A wire mesh machine is a specialized piece of equipment designed to produce various types of triedgaas produkten, such as roestfrij stiel laske gaas, chain link fence mesh, or woven polyester mesh. These wire mesh making machines automate the process of cutting, bending, welding, or weaving metal wires—usually made from materials like galvanized steel, stainless steel, or iron—into precise grid patterns.

Wire mesh machines are widely used in industries such as construction, agriculture, mining, and fencing production. They improve efficiency, reduce labor costs, and ensure consistent product quality. Depending on the wire mesh type, a wire mesh machine can feature programmable settings for mesh size, wire diameter, and panel dimensions, allowing for high customization and production flexibility.

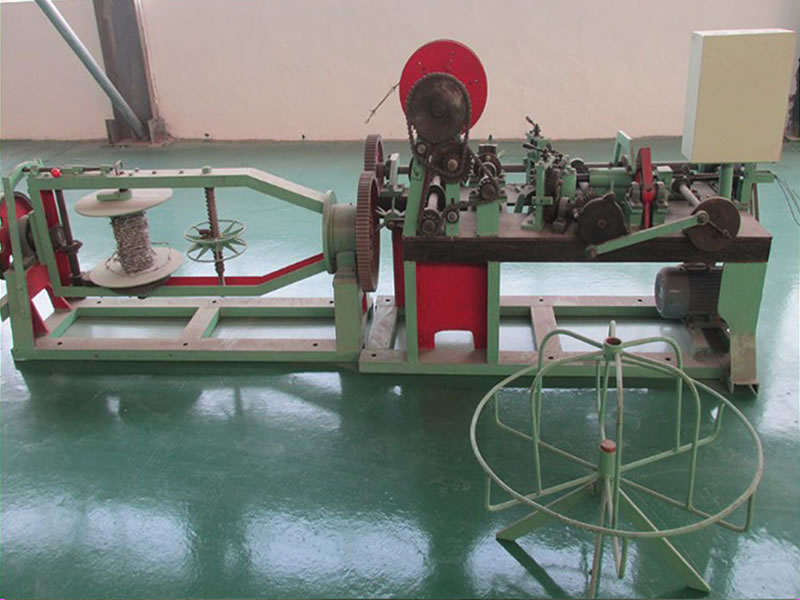

Advanced models may include automatic feeding systems, welding units, mesh rolling, and cutting devices, supporting both small-scale workshops and large-scale industrial operations. With robust construction and easy maintenance, wire mesh machines are essential for manufacturers seeking high output and precision.