I-Metal wire yinxalenye ebalulekileyo kushishino lwanamhlanje kunye nobomi bemihla ngemihla. Yintonga ebhityileyo, ebhetyebhetye okanye intonga yentsimbi eyenziwa ngokuzoba isinyithi kwidayisi. Ngokuqina kwayo okuphezulu kunye nokuguquguquka, ucingo lwentsimbi lusetyenziswa ngokubanzi kwiinkalo ezahlukeneyo ukusuka kulwakhiwo kunye nokuvelisa ukuya kubugcisa kunye ne-elektroniki.

Enye yezona zinto zibalulekileyo zocingo lwetsimbi kukuqiniswa kwayo kobunzima. Iintsimbi ezifana nentsimbi, ubhedu, i-aluminiyam, kunye ne-titanium ziqhele ukusetyenziswa ukuvelisa ucingo, nganye inika izibonelelo ezithile. Intambo yentsimbi, umzekelo, iyaziwa ngokuhlala kwayo kwaye isetyenziswa ngokubanzi kwiibhulorho ezimisiweyo, ukubiyela, kunye nokuqiniswa kwezakhiwo zekhonkrithi. Ucingo lwe-Copper, kunye ne-conductivity yayo egqwesileyo, ngumqolo wocingo lombane kunye nonxibelelwano.

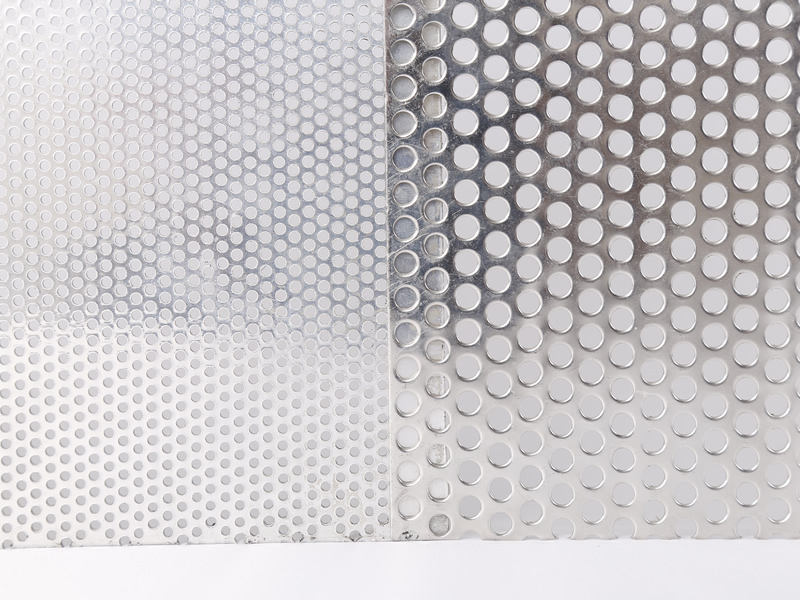

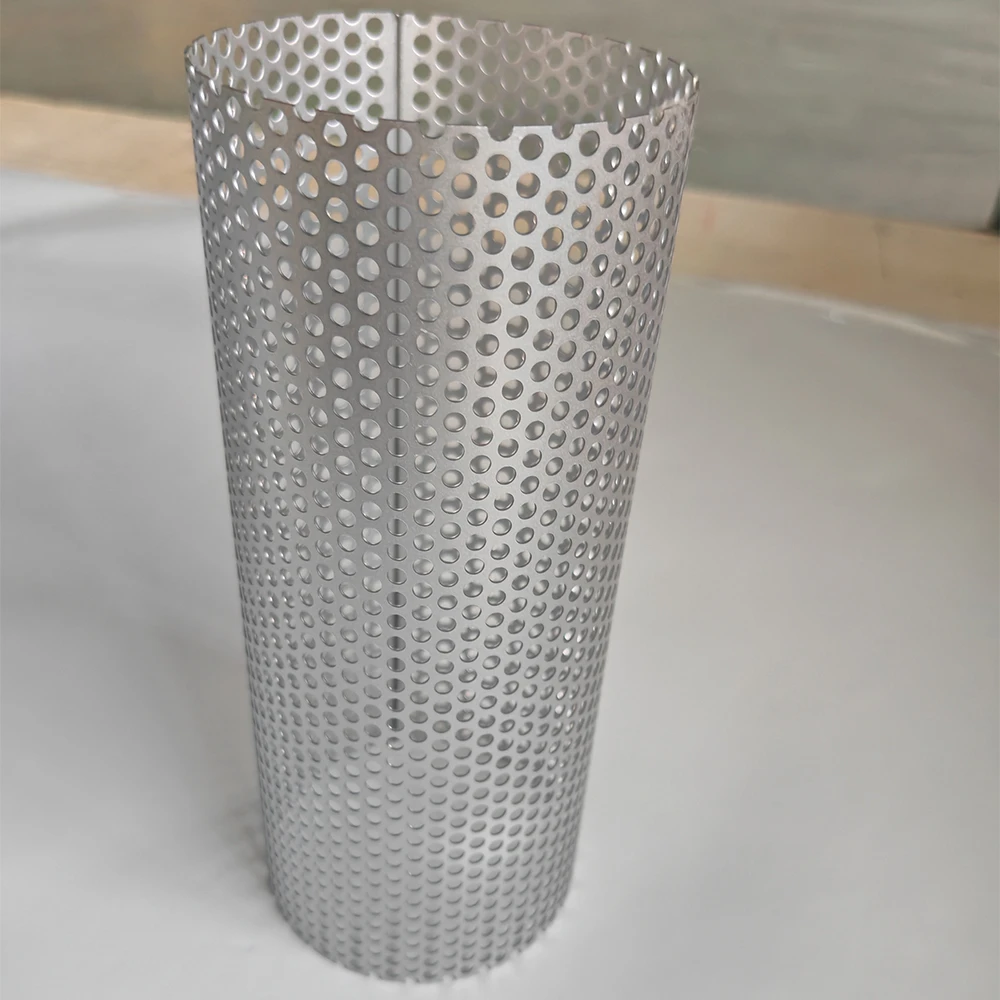

Kwishishini lokwakha, ucingo lwentsimbi ludlala indima ebalulekileyo. Isetyenziswa kwizinto ezibophelelayo, ukuqiniswa kwesakhiwo, nanjengamacandelo omnatha okanye iinkqubo zokubiya. I-welded wire mesh, eyenziwe kwiingcingo zetsimbi ezidibeneyo kwii-intersections, yinto eqhelekileyo kwinkxaso ye-slab yekhonkrithi. Ucingo oluhlabayo, olunye uhlobo locingo lwentsimbi, lubalulekile kukhuseleko lweperimeter kwindawo yezolimo neyomkhosi.

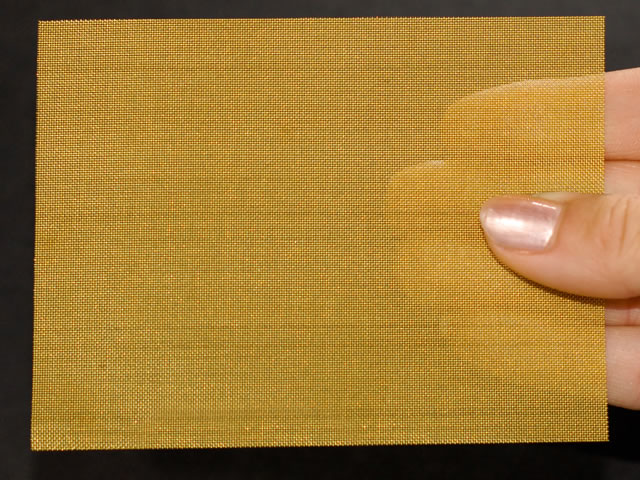

Iingcingo zesinyithi nazo ziyimfuneko kwihlabathi le-elektroniki. Iingcingo zobhedu ezincinci kunye ne-aluminium zisetyenziselwa ukwenza iisekethe, i-windings kwiimotor kunye ne-transformers, nakwiindibano zentambo. Ezi ngcingo kufuneka zenziwe ngokuchanekileyo ukuqinisekisa ukuxhathisa umbane ophantsi kunye nokusebenza okungaguqukiyo.

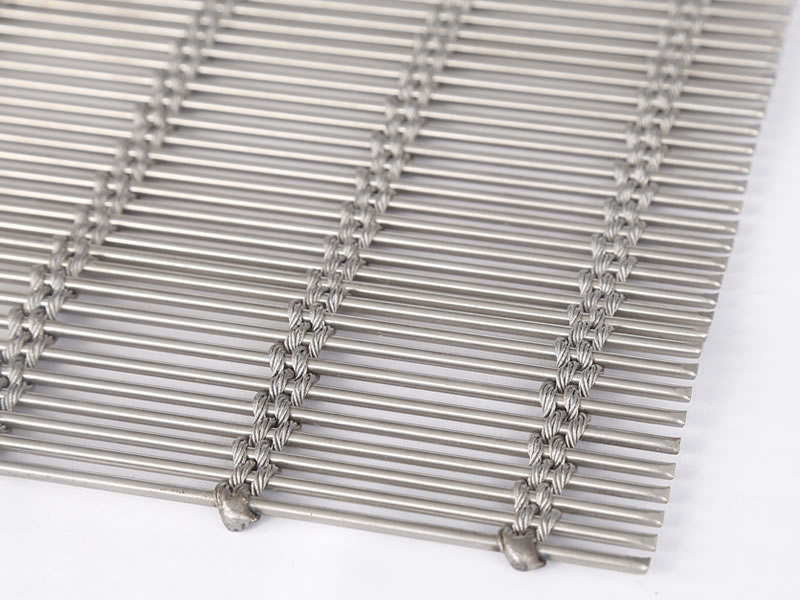

Ukongeza ekusebenziseni imboni, ucingo lwetsimbi lufumene indawo yobugcisa kunye noyilo. Amagcisa asebenzisa ucingo kwimifanekiso eqingqiweyo, ukwenza ubucwebe, kunye nobugcisa bokuhombisa ngenxa yokuguquguquka kunye nokukwazi ukubamba imilo. Isibheno sayo sobuhle esidityaniswe nezinto eziluncedo zesakhiwo siyenza ibe yinto eyintandokazi phakathi kwabayili.

Enye yeenzuzo zocingo lwetsimbi kukuhlaziywa kwayo. Iingcingo zetsimbi, ngakumbi ezo zenziwe nge-aluminium kunye nobhedu, zingancibilika kwaye zisetyenziswe kwakhona ngaphandle kokulahlekelwa iimpawu zazo. Oku kunegalelo kuzinzo kunye nokunciphisa impembelelo yokusingqongileyo.

Ukuveliswa kocingo lwentsimbi kubandakanya iinkqubo ezininzi ezinjengomzobo, ukufakwa kwe-anneal, kunye nokwaleka. Umzobo unciphisa ububanzi ngelixa ukhulisa ubude kunye namandla. I-anealing ithambisa isinyithi ukuphucula ukuguquguquka, kunye neengubo ezifana ne-zinc (i-galvanization) okanye iplastiki igalelwe ukomeleza ukuxhathisa ukudleka.

Ukuqukumbela, ucingo lwetsimbi luyinto esisiseko kumacandelo amaninzi. Ukuguquguquka kwayo, amandla, kunye nokuguquguquka kwayo kuqinisekisa ukuba iyaqhubeka ukudlala indima ebalulekileyo kumashishini emveli kunye namashishini asakhulayo. Kungakhathaliseki ukuba kubunjineli obunzima okanye kwiinkqubo ze-elektroniki ezithambileyo, ukubaluleka kocingo lwetsimbi akukwazi ukugqithiswa.