Metal wire is an essential component in modern industry and daily life. It is a slender, flexible strand or rod of metal that is typically made by drawing the metal through a die. With its high tensile strength and adaptability, metal wire is widely used in various fields ranging from construction and manufacturing to art and electronics.

One of the most important features of metal wire is its strength-to-weight ratio. Metals such as steel, copper, aluminum, and titanium are commonly used to produce wire, each offering specific benefits. Steel wire, for instance, is known for its durability and is widely used in suspension bridges, fencing, and reinforcement in concrete structures. Copper wire, with its excellent conductivity, is the backbone of electrical wiring and telecommunications.

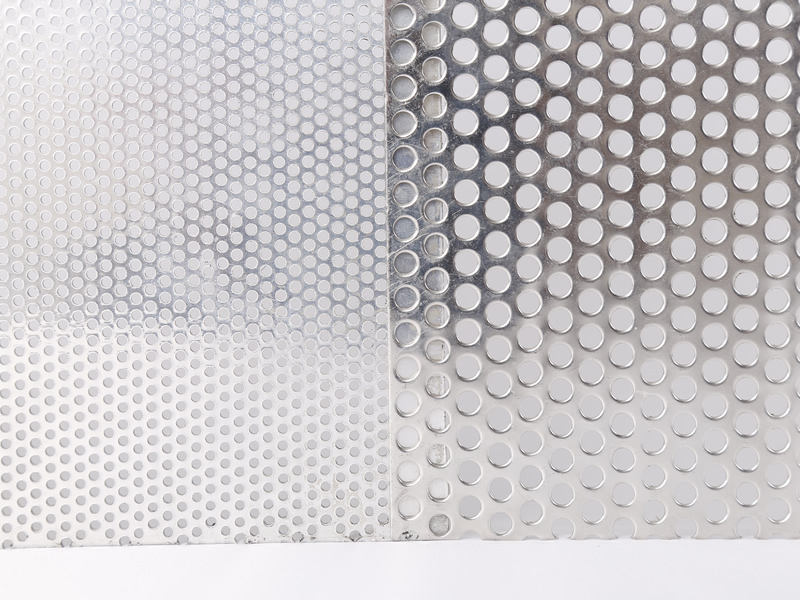

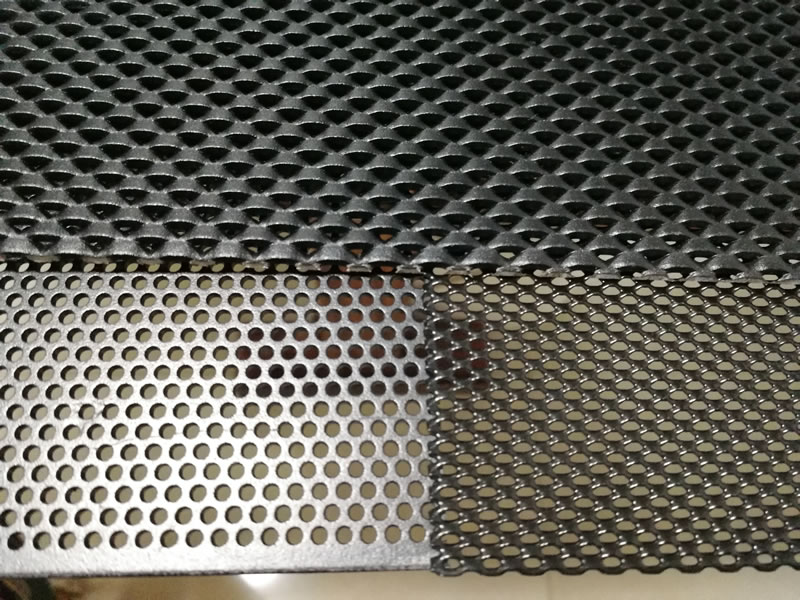

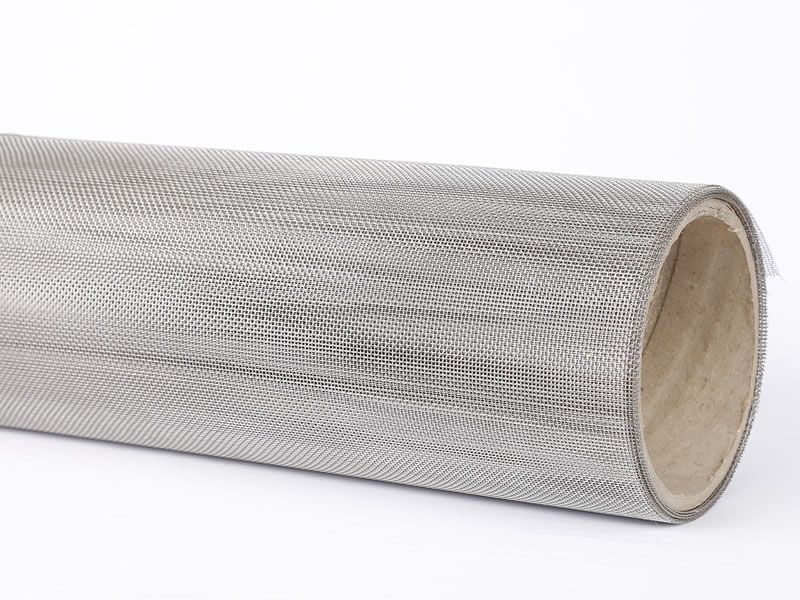

In the construction industry, metal wire plays a critical role. It is used in binding materials, structural reinforcement, and as components of mesh or fencing systems. Welded wire mesh, made from steel wires joined at intersections, is a common material in concrete slab support. Barbed wire, another form of metal wire, is crucial for perimeter security in agricultural and military settings.

Metal wire is also indispensable in the world of electronics. Thin copper and aluminum wires are used to create circuits, windings in motors and transformers, and in cable assemblies. These wires must be precisely manufactured to ensure low electrical resistance and consistent performance.

In addition to industrial use, metal wire has found a place in art and design. Artists use wire for sculptures, jewelry-making, and decorative crafts due to its flexibility and ability to hold shape. Its aesthetic appeal combined with structural utility makes it a favorite material among designers.

One of the advantages of metal wire is its recyclability. Metal wires, especially those made of aluminum and copper, can be melted down and reused without losing their properties. This contributes to sustainability and reduces environmental impact.

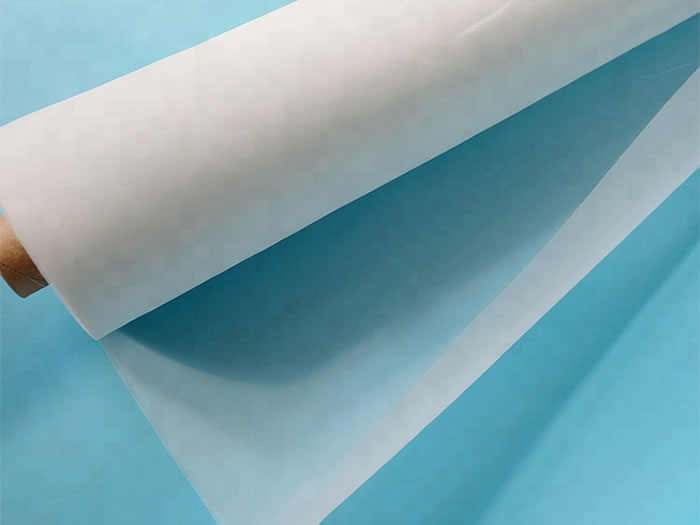

The production of metal wire involves several processes such as drawing, annealing, and coating. Drawing reduces the diameter while increasing length and strength. Annealing softens the metal to improve flexibility, and coatings like zinc (galvanization) or plastic are applied to enhance corrosion resistance.

In conclusion, metal wire is a foundational material in many sectors. Its versatility, strength, and adaptability ensure that it continues to play a vital role in both traditional and emerging industries. Whether in heavy-duty engineering or delicate electronic systems, the significance of metal wire cannot be overstated.