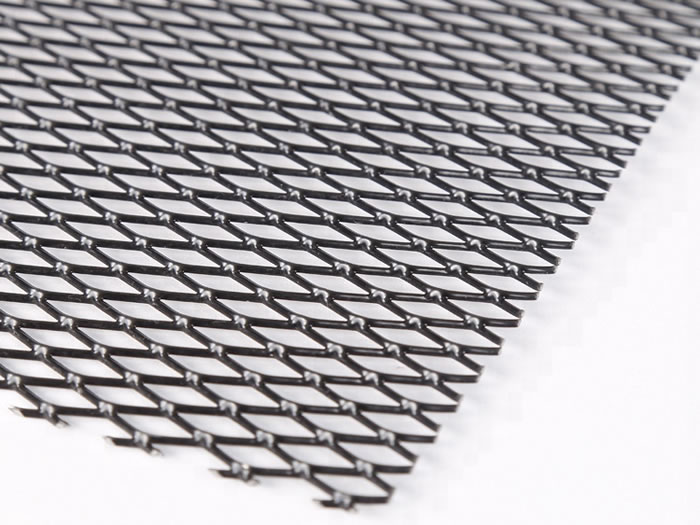

Wire mesh products are among the most versatile and widely used materials in both industrial and commercial applications. Composed of interlinked metal wires, wire mesh can be manufactured in various patterns, sizes, and metals, offering a combination of strength, durability, and flexibility. From construction and agriculture to security and filtration, wire mesh plays a vital role in modern infrastructure and technology.

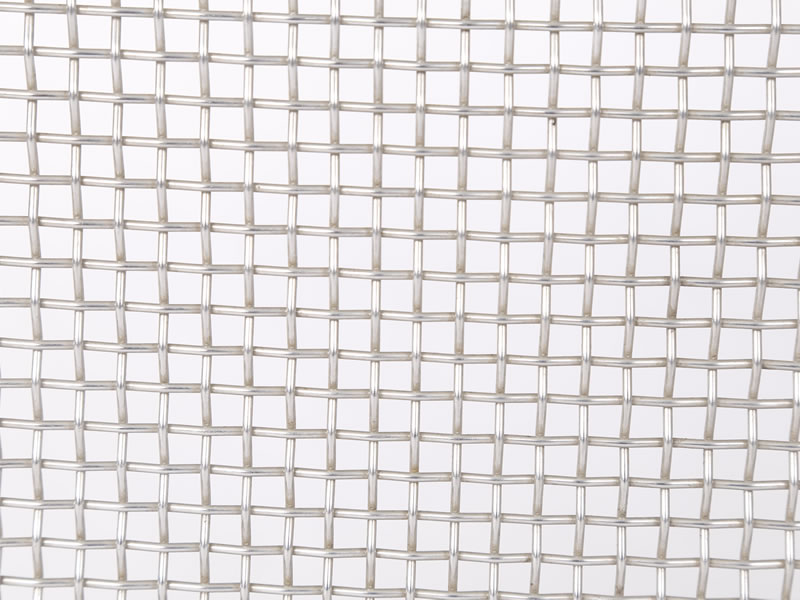

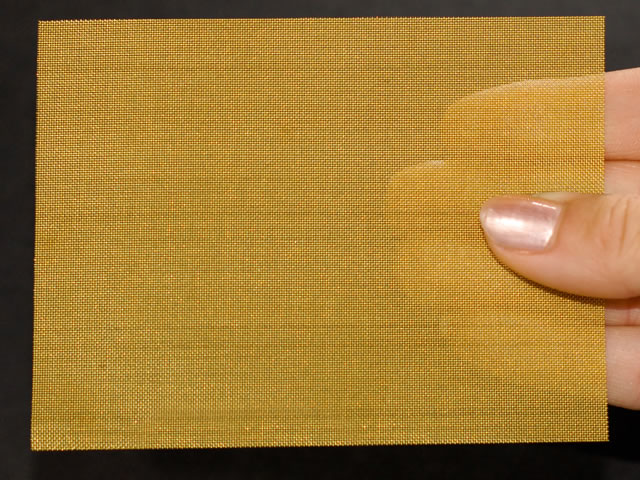

Wire mesh is typically made by welding or weaving metal wires into a grid pattern. Common materials used include stainless steel, galvanized steel, aluminum, and copper. The choice of material depends on the application and desired properties such as corrosion resistance, conductivity, or tensile strength. For example, stainless steel mesh is favored in environments where rust resistance is essential, while galvanized mesh offers a more cost-effective option for general outdoor use.

One of the key applications of wire mesh products is in the construction industry. Welded wire mesh is often used to reinforce concrete in buildings, roads, and tunnels. It provides structural support while allowing for better distribution of load and resistance to cracking. Wire mesh is also used for safety barriers, fencing, and scaffolding platforms. Its strength and ability to be shaped into various forms make it an indispensable component of modern construction projects.

In agriculture, wire mesh serves many functions such as animal enclosures, crop protection, and trellising for climbing plants. The mesh provides a physical barrier without obstructing visibility or airflow, which is especially important for livestock containment and garden protection. Different mesh sizes and gauges are used depending on the animal species or agricultural purpose.

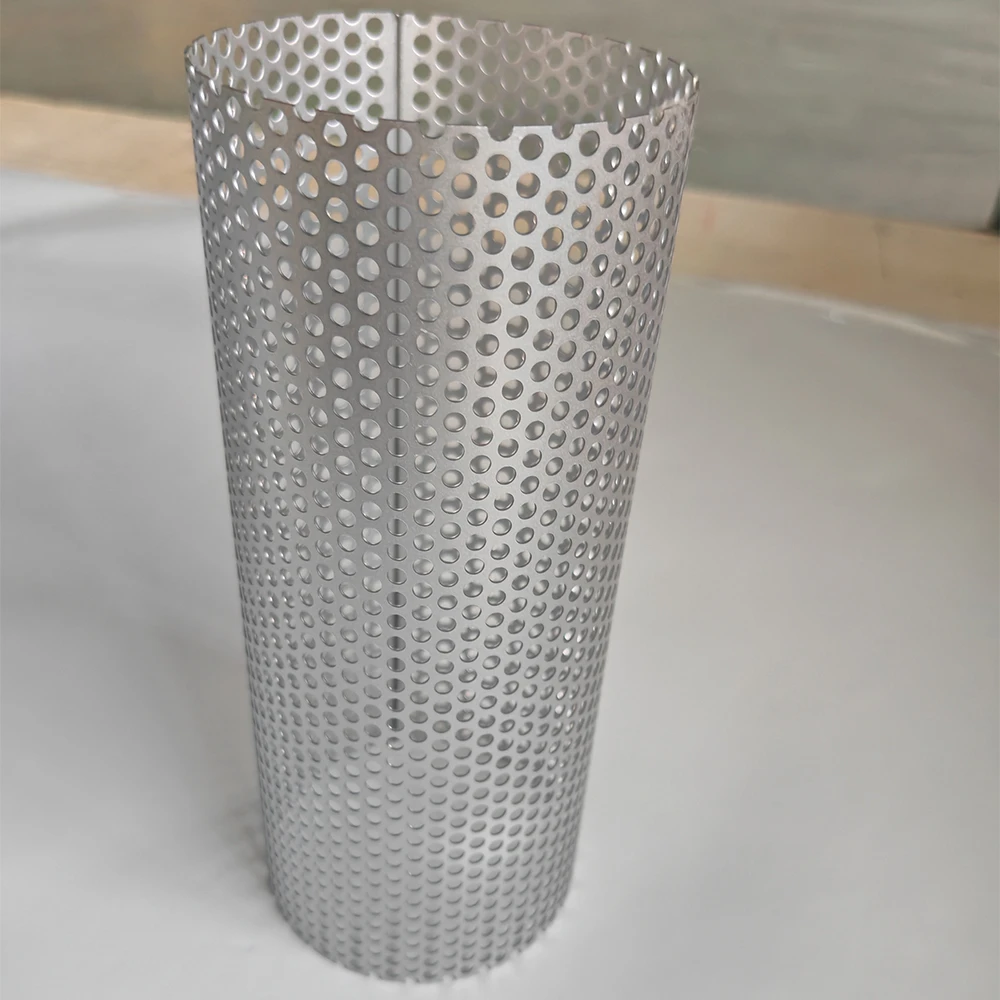

Wire mesh is also essential in industrial and commercial filtration systems. Fine woven meshes are used to filter liquids, gases, and even light particles in industries like chemical processing, food production, and water treatment. The precision and uniformity of the mesh make it ideal for maintaining purity and consistency in filtration applications.

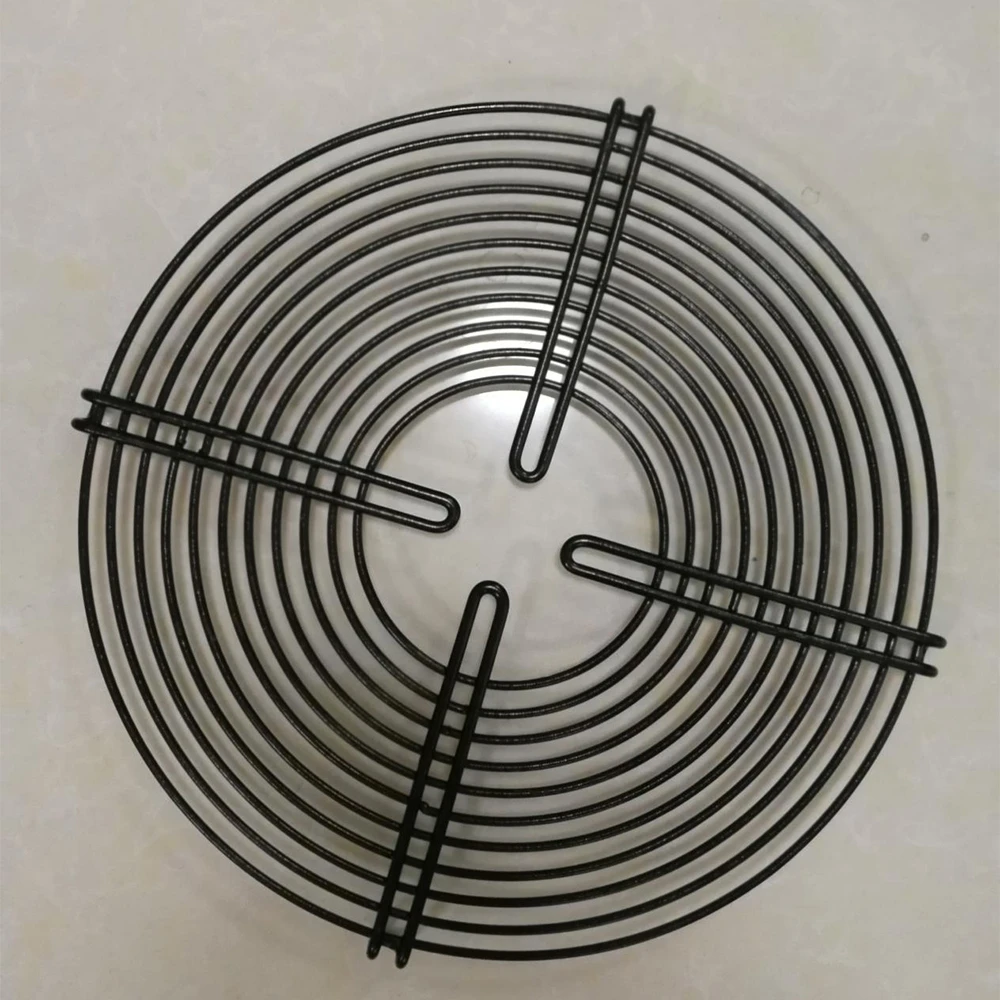

Security and safety are other major fields where wire mesh products excel. From window guards and security screens to machine guards and protective cages, wire mesh can provide a high level of safety without sacrificing visibility. It is also widely used in prisons, military installations, and secure facilities where both strength and transparency are required.

In recent years, wire mesh has also found use in interior design and architecture. Designers use decorative mesh panels for walls, ceilings, and furniture to achieve a modern, industrial aesthetic. The combination of strength and visual appeal makes wire mesh a favorite material in contemporary design.

In summary, wire mesh products are highly adaptable materials that offer numerous benefits across multiple industries. Their wide range of applications, from heavy-duty construction to delicate filtration, demonstrates their unmatched versatility. As industries evolve, the demand for innovative and reliable wire mesh solutions continues to grow.