Is Metal Clad Wire Strong

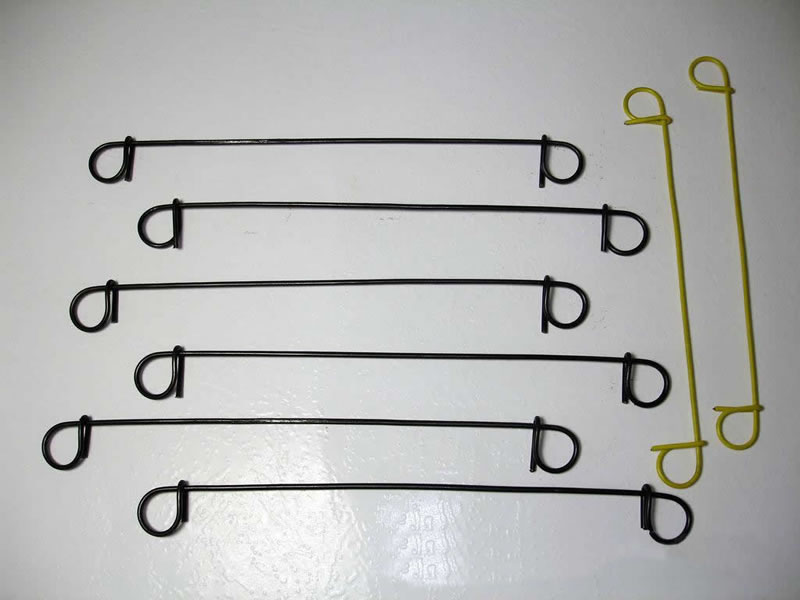

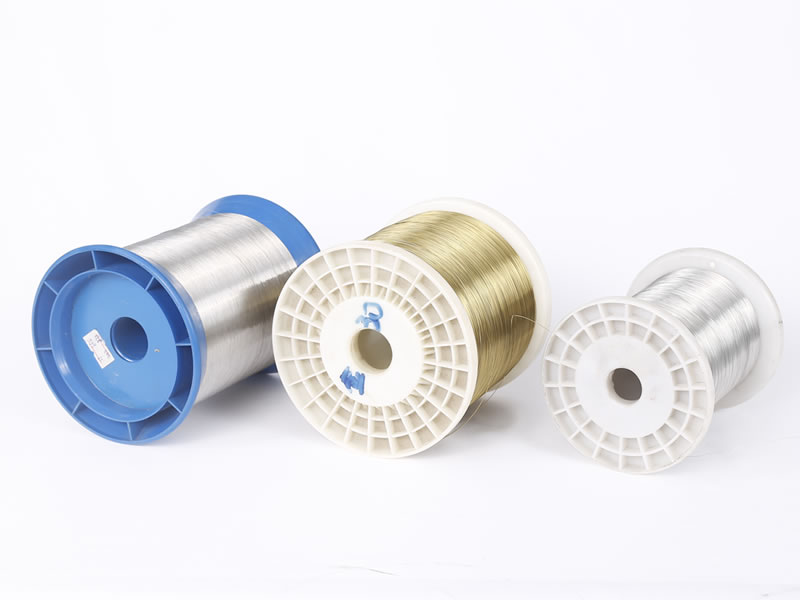

Yes, Metal Clad Wire can be very strong, depending on the type of metal used, its diameter, and how it’s processed. For example, steel wire fittings—especially high-carbon or stainless steel—is known for its excellent tensile strength and durability, making it ideal for heavy-duty applications like construction reinforcement, suspension bridges, and fencing. On the other hand, metals like copper or aluminum are softer and more flexible, which makes them less strong but better suited for electric tie wire and applications requiring malleability.