Hit enter to search or ESC to close

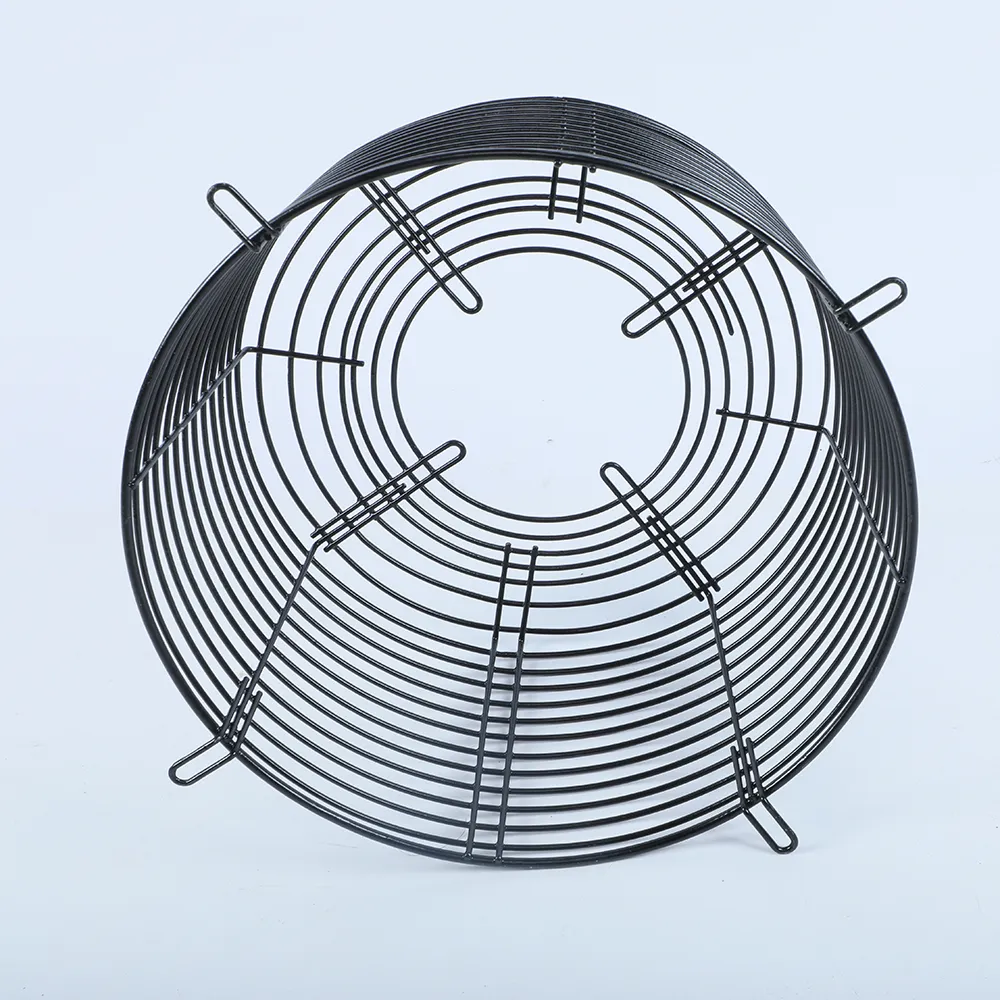

316 Stainless Steel Welded Wire Mesh – Durable, Corrosion Resistant, Premium Quality

(316 stainless steel welded wire mesh)

The rising demand for advanced filtration and reinforcement materials has spotlighted 316 stainless steel welded wire mesh

as a leading solution across various industries. Known for its exceptional chemical and mechanical properties, stainless steel 316 welded wire mesh achieves a delicate balance between durability, corrosion resistance, and versatility. The specialized alloy composition, including 16–18% chromium, 10–14% nickel, and 2–3% molybdenum, elevates its resilience far beyond standard stainless grades, particularly against chloride-induced pitting. The robust welded intersections confer mechanical integrity, making stainless steel 316 wire mesh ideal for both static and dynamic environments. These unique structural and compositional strengths ensure extensive use in marine, pharmaceutical, food processing, and architectural applications.

316 stainless steel wire mesh boasts a suite of technical advantages that distinctly position it above other wire mesh variants. Its molybdenum-enhanced microstructure enables superior resistance to both general and localized corrosion, including intergranular attack, which is a critical factor in harsh environments. Laboratory studies show 316 mesh maintains over 94% tensile strength after prolonged exposure to saline conditions for 5,000 hours, while comparable meshes degrade by up to 28%. Its temperature resistance extends up to 870°C (1,598°F) under intermittent service, and 925°C (1,697°F) for short periods, outclassing 304 stainless wire mesh by over 150°C. These thermal properties are vital for processing and filtration operations involving significant temperature swings. Furthermore, the precise welds in 316 stainless steel welded wire mesh reduce the risk of mesh deformation during installation and use, ensuring dimensional stability and reliability throughout its service life.

Selecting the right manufacturer for wire mesh stainless steel 316 is crucial for achieving optimal performance and value. The following table presents a data-driven comparison of four leading global suppliers, evaluating core metrics such as mesh uniformity, corrosion resistance, delivery time, and customization options:

| Manufacturer | Mesh Uniformity (%) | Corrosion Resistance (Salt Spray Test, h) | Delivery Time (days) | Customization Options |

|---|---|---|---|---|

| MeshPerfect (USA) | 99.7 | 5000+ | 14–21 | Extensive (aperture, roll width, welding pattern) |

| SteelGrid Europe | 98.5 | 4200 | 18–25 | Standard (basic aperture, minimum width) |

| AsiaMesh Industries | 97.8 | 3900 | 10–18 | Moderate (varied gauge, aperture) |

| InoxPro Solutions | 99.2 | 4800+ | 16–24 | Comprehensive (custom weave, form factors) |

The highest mesh uniformity and corrosion resistance were recorded by MeshPerfect and InoxPro Solutions, indicating the importance of partnering with suppliers maintaining rigorous quality controls and advanced processing technology. Delivery timelines and customization capabilities also play a pivotal role in fulfilling specific project requirements.

Modern industries require flexibility in product dimensions, apertures, strength, and finish. 316 stainless steel wire mesh can be tailored to precisely match such specifications. Customization ranges from mesh opening size (as fine as 0.025 mm up to coarse 50 mm grids), wire diameter (0.5 mm to 6 mm), and mesh width and length, to additional treatments such as passivation, electro-polishing, and anti-bacterial coatings. Innovative welding patterns can be specified to enhance load-bearing capacity or optimize filtration characteristics, essential for industries such as petrochemicals or medical processing. Manufacturers employ advanced computer-controlled welding and rolling systems, ensuring each batch adheres to strict tolerance margins, typically within ±2%. Custom labeling, packaging, and just-in-time logistics further support integrators and end-users in complex supply chains.

The application spectrum for wire mesh stainless steel 316 is vast, spanning contamination control, safety barriers, architectural features, and process filtration. In the pharmaceutical sector, one major multinational deployed 316 welded wire mesh filters to achieve clean room compliance; subsequent testing saw biocontaminant presence lowered by 87% compared to previous filter regimes, reducing product recalls and boosting throughput by 19%. Coastal power stations utilize 316 stainless steel welded wire mesh as anti-corrosion fencing, reporting maintenance savings of more than $120,000 annually due to extended replacement cycles. In fine food processing, mesh with a 0.063 mm opening size ensures exclusion of particulates larger than 40 microns, safeguarding product purity. Infrastructure projects favor 316 mesh reinforcement for its ability to resist salt-polluted urban rainfall, thereby extending the lifespan of concrete armor by a projected 15+ years.

The operational success of any project hinges on the reliable quality and longevity of core materials. Reputable suppliers implement comprehensive quality protocols throughout manufacturing, including laser-measured aperture verification, continuous tensile testing, and exposure to over 4,800-hour salt fog simulations. 316 stainless steel welded wire mesh is non-reactive to most acids and is rated for upwards of 25 years in marine or chemically strenuous environments, making it a stalwart investment for mission-critical applications. The material’s smooth welds minimize microbial harboring risks—crucial in food and medical installations—while its resistance to fatigue loading ensures minimal maintenance in structural roles. In terms of environmental performance, the metal is 100% recyclable and well-aligned with sustainable construction and process mandates.

The evidence is clear: 316 stainless steel welded wire mesh delivers unmatched performance in resilience, customization, and operational value across challenging industries. Its strategic alloy design, documented by independent laboratories and in-field results, ensures a service life and reliability that set it apart from alternatives. By assessing manufacturer data, leveraging bespoke fabrication, and selecting a supplier committed to strict quality assurance, stakeholders can realize projects that meet or surpass regulation and expectation. For critical filtration, structural reinforcement, or demanding marine and process settings, the stainless steel 316 wire mesh stands as a proven, cost-efficient, and sustainable material of choice.

(316 stainless steel welded wire mesh)

JOIN OUR NEWSLETTER

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.