Hit enter to search or ESC to close

High Quality 3mm Metal Wire – Durable & Versatile Best 3mm Perforated Metal Sheet & Steel Wire Price

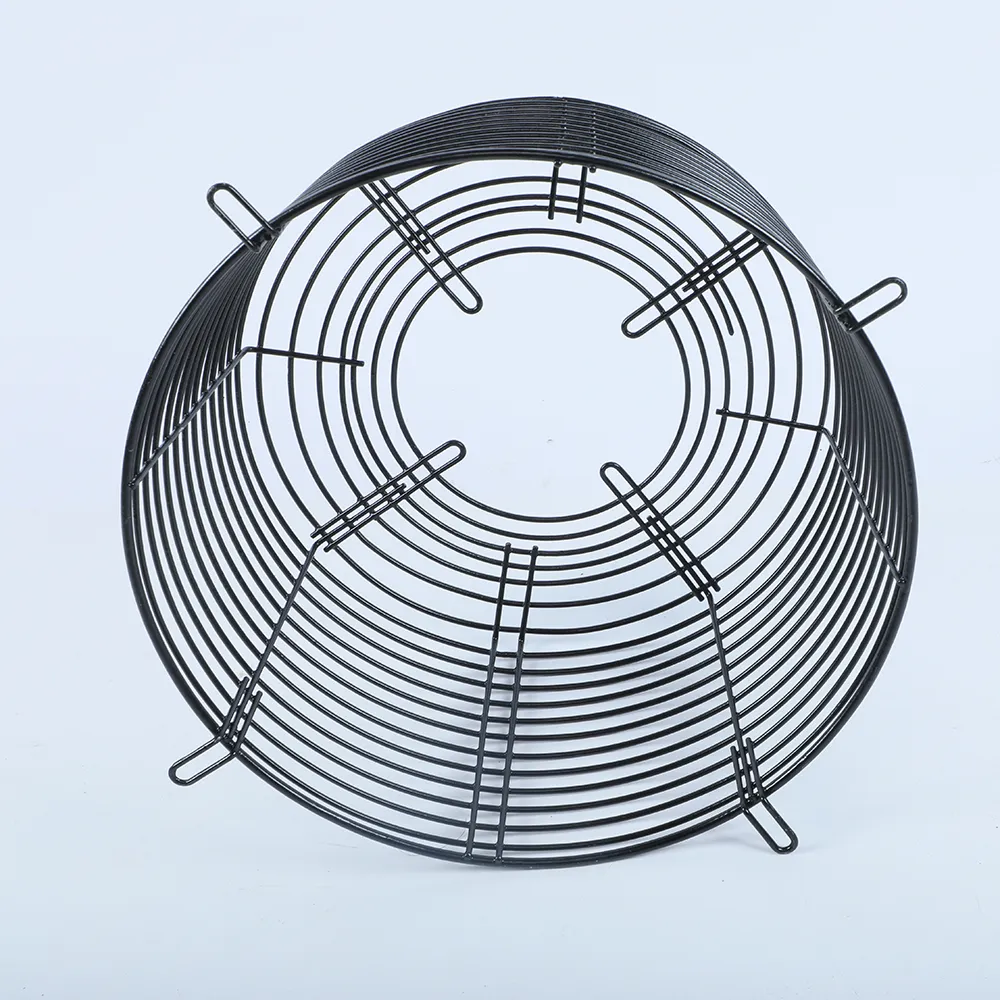

(3mm metal wire)

The demand for 3mm metal wire

has emerged across a diverse spectrum of industries, including construction, manufacturing, fencing, security, and creative art installations. Its versatility is backed by robust mechanical properties, cost-effectiveness, and scalability for large and small-scale projects. This post presents a structured deep dive into the unique technical specifications, manufacturer differentiators, price variables, and latest usage cases of 3mm wire, perforated sheets, and other affiliated metal products in the global supply chain.

The global metal wire market has grown significantly, with the 3mm segment accounting for a substantial share. According to recent data, steel wire consumption is projected to rise by 4.8% annually, with the construction sector absorbing nearly 38% of total wire products. These numbers reflect not only the widespread utility but also sharpen the focus on supplier innovation, pricing transparency, and tailored manufacturing solutions for highly specific industry needs.

Through comprehensive analysis, this blog will systemically explore the distinguishing features, comparative advantages, and advanced applications of 3mm wire and its related metal products in today's competitive market landscape.

The mechanical excellence of 3mm metal wire is underscored by key properties such as tensile strength, corrosion resistance, and ease of fabrication. With diameters precisely engineered to 3mm ±0.05mm, manufacturers utilize a mix of carbon steel, stainless steel (304, 316), galvanized coatings, and specialty alloys to balance strength and malleability.

Performance Data:

| Wire Type | Tensile Strength (MPa) | Corrosion Resistance | Elongation (%) | Available Coil Weight (Kg) |

|---|---|---|---|---|

| Stainless Steel 304 | 600-850 | Very High | 15-22 | 5–1000 |

| Carbon Steel | 350-650 | Low-Moderate | 10-18 | 10–2000 |

| Galvanized Steel | 370-690 | High | 13-18 | 10–2000 |

The data highlights why 3mm variants are preferred for fencing, mesh panels, balustrades, and machinery parts. High-tensile versions cater to dynamic loads while stainless grades provide longevity in corrosive or outdoor environments. Additionally, tight gauge control ensures compatibility with automated bending and welding systems, reducing assembly costs and improving product uniformity for manufacturers.

Selecting the right supplier is crucial when sourcing 3mm metal wire, 3mm perforated metal sheet, or evaluating 3mm steel wire price for bulk procurement. Key criteria include product consistency, lead time, compliance with standards (e.g., ASTM, EN, ISO), and after-sales support. The following table profiles three prominent manufacturers for comparative clarity:

| Manufacturer | Annual Capacity (Tons) | Quality Certification | 3mm Steel Wire Price (per ton) | Global Distribution |

|---|---|---|---|---|

| SteelPro Metals Ltd. | 50,000 | ISO 9001, CE | $850–$900 | Americas, Europe, MENA |

| HexaWire Industries | 37,000 | ASTM, RoHS | $870–$930 | Asia, Oceania, Africa |

| PrimeWeld Steels | 45,000 | EN 10270, ISO 14001 | $820–$880 | Europe, North America |

Price differentials stem from material sourcing, in-house processing technology, and logistics efficiency. While PrimeWeld offers the most competitive pricing, SteelPro Metals leads with broader certifications and global reach. It is essential to match supply reliability and product standards with project requirements, especially for large-scale infrastructural or OEM projects.

Beyond standard production, the market increasingly values bespoke solutions for 3mm metal wire and perforated metal sheets. Customization options span material composition (e.g., anti-bacterial alloys, high-carbon specialties), surface treatments (PVC-coating, powder painting), coil or straight-cut formats, and exact length-tolerance configurations.

Leading manufacturers employ state-of-the-art extrusion, cold drawing, and laser-perforation systems, capable of delivering tolerances as tight as ±0.01mm for high-precision demands. Value-added options include:

Such tailored approaches help clients optimize mechanical performance, reduce installation time, and enhance end-product branding—critical in sectors such as energy infrastructure, automated warehousing, or defense perimeter protection.

The true test of 3mm wire’s value lies in its field performance. Actual deployment confirms the wire’s structural stability, adaptability, and return on investment. Below are three representative cases across construction, manufacturing, and transport sectors:

| Industry | Client Application | Wire Type | Benefits Achieved | Service Life (Estimated) |

|---|---|---|---|---|

| Construction | Mesh Reinforcement | Galvanized 3mm Steel Wire | 33% faster installation, 27% lower rust complaints | 20+ years |

| Automotive | Component Spring & Retainers | Stainless Steel 304 | Weight reduction by 12%, zero corrosion failures | 15 years |

| Food Processing | Hygienic Conveyor Belts | Custom 3mm Perforated Sheet | 99% cleaning efficiency, cut cleaning time by 40% | 10 years |

Decisive factors for long-term success include wire consistency, surface finish, and resilience to environmental factors. These case studies demonstrate measurable improvements in efficiency and lifespan, outperforming older generations of wire and mesh products.

Staying ahead requires a keen assessment of market trends and price dynamics. Over the past year, global 3mm steel wire prices have fluctuated within a $790–$950 per ton range, primarily influenced by raw material costs, international logistics, and bulk contract demand. Europe and North America remain the largest consumers, with Asia-Pacific economies emerging as both producers and consumers.

The market for 3mm perforated metal sheets is expanding at a CAGR of 6.2%, fueled by their rising adoption in acoustic panels, filtration systems, and architectural facades. Innovations in automated laser perforation and eco-friendly surface treatments are driving differentiation. About 43% of surveyed buyers reported supplier switching in search of better customization and value-added services.

Additionally, sustainability pressures are encouraging adoption of recyclable alloys and energy-efficient production lines. Top-performing suppliers are investing in closed-loop water systems and digital process monitoring to lower costs and improve environmental compliance.

In summary, 3mm metal wire continues to set the benchmark for reliability, technical flexibility, and cost optimization across global industries. The synergy of high-tensile strength, superior finishing, and custom configurations empowers sectors from superstructure reinforcement to advanced manufacturing lines. Supplier selection, based on certified quality and adaptive production capabilities, remains paramount for achieving operational success.

As technology, sustainability, and application diversity expand, the future outlook for 3mm wire points to smarter integration with digital monitoring, automated fabrication, and innovative alloys. Industry players who leverage these advancements will capture larger shares of this expanding market and set new standards for engineering excellence.

(3mm metal wire)

JOIN OUR NEWSLETTER

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.