Understanding Stainless Steel Wire Mesh: An Essential Component for Industrial Innovation

In the diverse landscape of industrial materials, stainless steel mesh for sale stands out as a critical element, enabling myriad applications across virtually every sector. From intricate filtration systems to robust architectural enhancements, the demand for high-performance stainless steel wire mesh continues to grow, driven by its unparalleled properties. As a B2B professional, understanding the nuances of this material is paramount for making informed procurement decisions that impact operational efficiency, product lifespan, and overall project success. This comprehensive guide delves into the technical aspects, applications, and strategic considerations for selecting the ideal stainless steel mesh for your specific requirements.

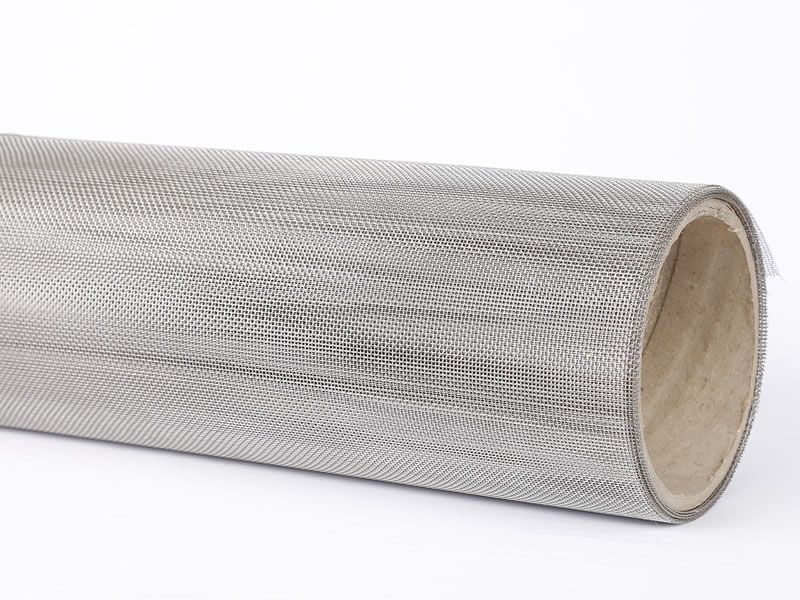

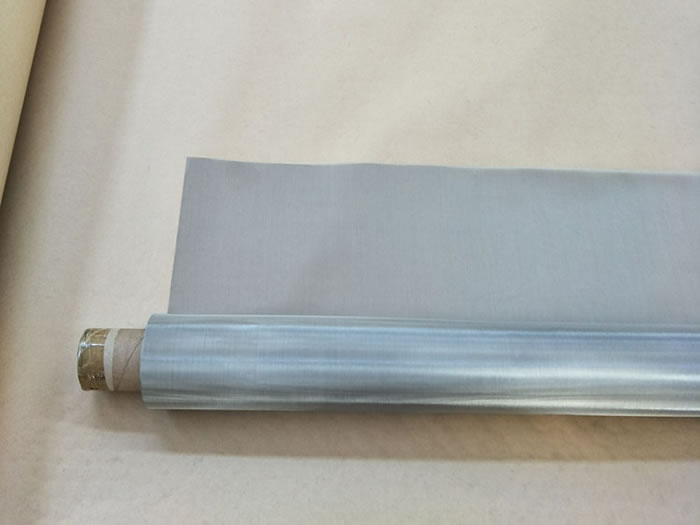

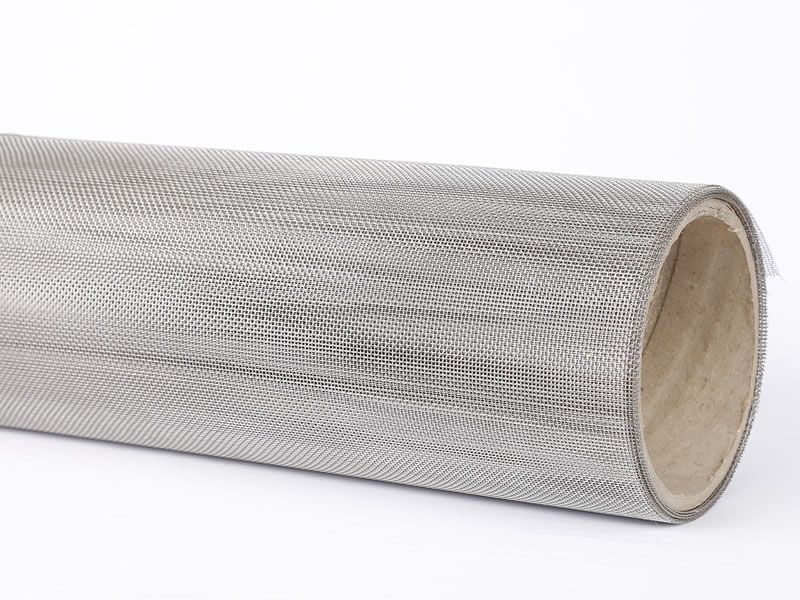

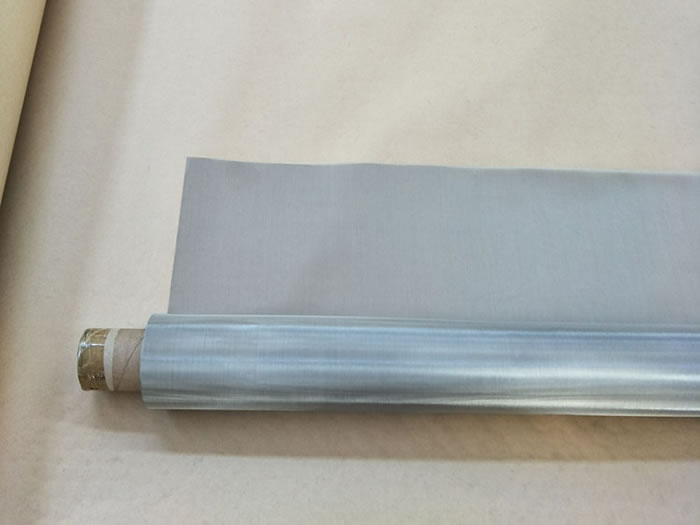

The market for stainless steel mesh for sale is dynamic, with innovations in material science and manufacturing processes constantly pushing the boundaries of what is achievable. Industry trends point towards increased demand for finer meshes for precise filtration, broader use of specialized alloys for extreme environments, and growing adoption in sustainable construction. Whether you require standard rolls of stainless steel wire mesh or custom-fabricated components, selecting a reputable supplier offering consistent quality and technical support is crucial.

The Advanced Manufacturing Process of Stainless Steel Wire Mesh

The production of high-quality stainless steel wire mesh involves a sophisticated multi-stage process that ensures uniformity, durability, and precise specifications. It typically begins with the selection of premium stainless steel alloys, such as 304, 316, 316L, or 321, chosen for their specific corrosion resistance, heat resistance, and mechanical properties. These alloys undergo a meticulous wire drawing process, reducing their diameter to the precise gauge required for the mesh. The primary manufacturing technique for wire mesh is weaving or welding.

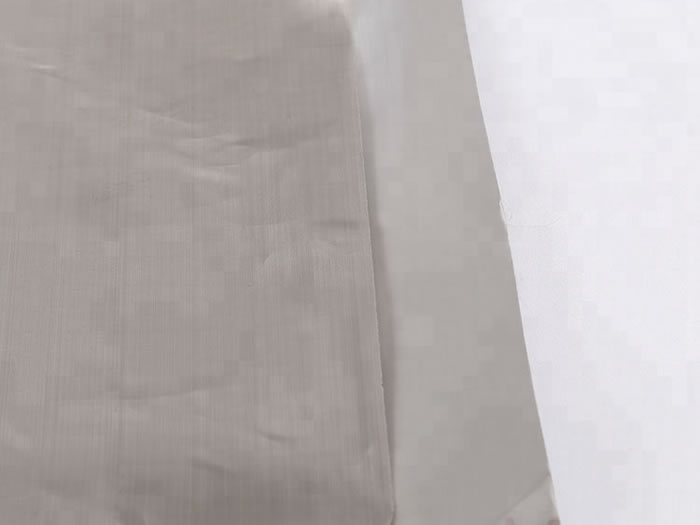

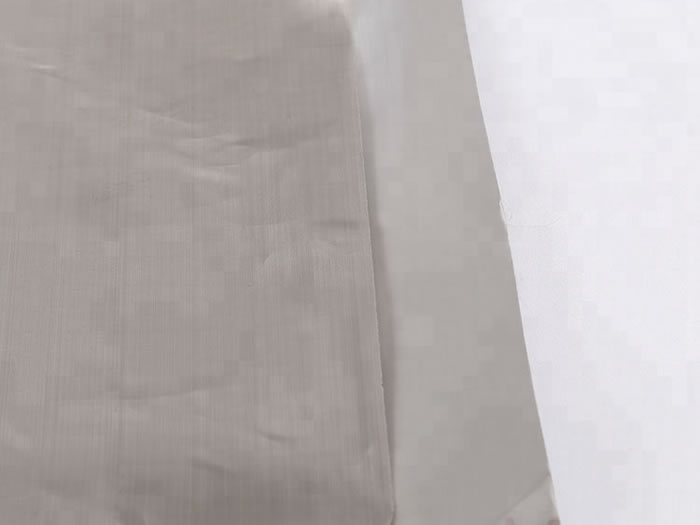

- Weaving: This involves interweaving warp (longitudinal) and weft (transverse) wires on specialized looms to create various patterns like plain weave, twilled weave, or Dutch weave. Plain weave offers robustness and uniform openings, ideal for general filtration. Twilled weave, with its stronger wire arrangement, provides increased strength and can accommodate heavier wires. Dutch weave, characterized by its tightly packed weft wires, offers superior filtration capabilities for very fine particles.

- Welding: For welded wire mesh, individual wires are resistance-welded at each intersection, forming a strong, rigid grid. This method is preferred for applications requiring structural integrity and defined openings, such as security barriers or reinforcing cages.

Post-processing includes cleaning, annealing (heat treatment to improve ductility and reduce stress), and precise cutting to size. Quality control is paramount throughout, adhering to international standards such as ISO 9001 for quality management and ASTM E2016 for mesh specifications. Rigorous inspection ensures precise mesh count, wire diameter, opening size, tensile strength, and freedom from defects. This stringent adherence to standards guarantees that the final stainless steel mesh for sale products meet the demanding requirements of industries like petrochemicals, metallurgy, and water treatment, offering exceptional lifespan and reliable performance in corrosive environments.

Key Technical Parameters and Specifications

When sourcing stainless steel wire mesh, a thorough understanding of its technical parameters is essential. These specifications define the mesh's performance characteristics and suitability for specific applications. Key parameters include:

- Mesh Count: The number of openings per linear inch, indicating the fineness of the mesh. A higher mesh count means smaller openings and finer filtration.

- Wire Diameter: The thickness of the individual wires. Thicker wires provide greater strength and durability but reduce the open area.

- Opening Size (Aperture): The clear space between adjacent parallel wires. This is crucial for filtration and screening applications.

- Open Area Percentage: The ratio of the open space to the total area of the mesh, expressed as a percentage. A higher open area allows for greater flow rates.

- Weave Pattern: Plain, Twilled, Dutch (Plain/Twilled), or crimped weaves, each offering distinct properties regarding strength, stability, and filtration capability.

- Material Grade: The specific stainless steel alloy (e.g., 304, 316, 316L), determining corrosion resistance, heat resistance, and mechanical strength.

Typical Stainless Steel Wire Mesh Specifications

| Mesh Count (per inch) |

Wire Diameter (mm) |

Opening Size (mm) |

Open Area (%) |

Weave Pattern |

| 4 |

0.90 |

5.45 |

74.0 |

Plain |

| 10 |

0.50 |

2.04 |

49.0 |

Plain |

| 50 |

0.18 |

0.328 |

27.0 |

Plain |

| 100 |

0.10 |

0.154 |

23.7 |

Plain |

| 200 |

0.05 |

0.077 |

23.0 |

Plain |

These parameters collectively determine the mesh's filtration efficiency, flow rate, mechanical strength, and resistance to clogging. Specifying these details precisely when procuring stainless steel mesh for sale ensures that the product performs optimally for its intended use, whether it's for particle separation, structural reinforcement, or decorative purposes.

Versatile Applications Across Diverse Industries

The inherent properties of stainless steel wire mesh – particularly its corrosion resistance, high tensile strength, and versatility in weave patterns – make it indispensable across a vast array of industrial sectors. Its application extends far beyond simple screening, playing a crucial role in enhancing efficiency and safety in demanding environments.

- Petrochemical and Chemical Industry: Used extensively for filtration in reactors, catalyst support grids, gas scrubbers, and strainers, where resistance to aggressive chemicals and high temperatures is critical. The mesh ensures purity of products and protection of downstream equipment.

- Water Treatment and Wastewater Management: Essential for pre-filtration, grit removal, fine screening, and filter support in municipal and industrial water treatment plants. Its anti-corrosive properties ensure longevity in aqueous environments.

- Mining and Metallurgy: Employed in screening and sizing of ores, aggregates, and other raw materials. Its durability stands up to abrasive conditions and heavy loads.

- Food and Beverage Processing: Used for sieving, grading, drying, and conveying various food products. The hygienic nature of stainless steel prevents contamination, making it compliant with strict food safety standards.

- Pharmaceutical Industry: Critical for precise particle separation, tablet pressing, and sterile air filtration in cleanroom environments, where material purity and non-reactivity are paramount.

- Architectural and Decorative Applications: Increasingly utilized for facades, railings, ceilings, and interior design elements due to its aesthetic appeal, durability, and low maintenance.

- Automotive and Aerospace: Found in exhaust systems, fuel filters, and sound attenuation components, benefiting from its heat and corrosion resistance.

In these applications, stainless steel wire mesh offers distinct advantages such as improved process efficiency through consistent filtration, reduced maintenance costs due to extended service life, and enhanced safety by containing hazardous materials. The robust construction and material integrity mean less downtime and more reliable operations for your industrial processes.

Advantages of Opting for Quality Stainless Steel Wire Mesh

Investing in high-quality stainless steel mesh for sale offers a multitude of technical and economic benefits for B2B applications. The unique properties of stainless steel, combined with precision manufacturing, result in a product that consistently outperforms alternatives in demanding environments.

- Superior Corrosion Resistance: Stainless steel contains chromium, which forms a passive, self-healing oxide layer that provides excellent resistance to rust, oxidation, and various chemical attacks. This is crucial in harsh industrial settings, extending the mesh's operational life significantly.

- High Strength-to-Weight Ratio: Despite being lightweight, stainless steel mesh exhibits remarkable tensile strength and durability, capable of withstanding significant mechanical stress, vibration, and impact without deforming or breaking.

- Temperature Resistance: Stainless steel retains its mechanical properties and structural integrity over a broad range of temperatures, from cryogenic to high-heat applications, making it suitable for processes involving extreme thermal conditions.

- Hygienic and Easy to Clean: Its smooth, non-porous surface makes it resistant to bacterial growth and easy to sanitize, a vital characteristic for applications in the food & beverage, pharmaceutical, and medical industries.

- Aesthetic Appeal: The bright, clean appearance of stainless steel, especially a finely woven stainless steel wire mesh roll, is highly valued in architectural and design applications, offering both functionality and modern aesthetics.

- Longevity and Low Maintenance: The inherent durability and resistance to degradation translate into a longer service life and reduced need for replacement or intensive maintenance, leading to significant long-term cost savings.

Choosing a high-grade stainless steel wire mesh ensures not just performance, but also contributes to the sustainability and cost-effectiveness of your operations. Its robust nature minimizes downtime and enhances the reliability of critical systems.

Choosing the Right Supplier: Manufacturer Comparison & Custom Solutions

The selection of a reliable manufacturer for stainless steel mesh for sale is as crucial as the product specifications themselves. A reputable supplier should demonstrate not only expertise in manufacturing but also a commitment to quality, adherence to international standards, and robust customer support. When evaluating manufacturers, consider their service history, certifications (e.g., ISO 9001, CE), production capacity, and flexibility in offering custom solutions.

Comparative Analysis of Common Stainless Steel Grades for Mesh

| Grade |

Key Characteristics |

Typical Applications |

Advantages |

| 304 (18/8) |

Good corrosion resistance, excellent formability, common grade. |

General industrial, architectural, food processing. |

Versatile, cost-effective, readily available. |

| 316 |

Enhanced corrosion resistance (molybdenum added), improved pitting resistance. |

Marine, chemical processing, pharmaceutical, medical. |

Superior performance in chloride environments. |

| 316L |

Low carbon version of 316, better for welding, prevents carbide precipitation. |

Welded structures, corrosive environments, high-purity applications. |

Excellent weldability, reduced intergranular corrosion risk. |

| 321 |

Titanium stabilized, good high-temperature strength, excellent creep resistance. |

Aircraft exhaust manifolds, furnace parts, expansion joints. |

Resists sensitization at elevated temperatures. |

Beyond standard offerings, many industrial applications require customized stainless steel wire mesh solutions. This might include specific mesh dimensions, unique weave patterns, specialized alloys for extreme chemical resistance, or custom fabrication into filters, baskets, or other components. A manufacturer capable of providing precision cutting, bending, welding, and forming can be a valuable partner. When discussing custom requirements, provide detailed blueprints, material specifications, and performance criteria to ensure the final product perfectly aligns with your operational needs.

Real-World Impact: Application Case Studies

The practical utility and transformative impact of stainless steel wire mesh are best illustrated through its successful deployment in various complex industrial scenarios. These cases highlight how tailored mesh solutions solve specific engineering challenges, leading to significant operational improvements.

- Petrochemical Filtration Upgrade: A major refinery needed to enhance the purity of its processed hydrocarbons while operating at elevated temperatures and pressures. By replacing existing filtration media with custom-fabricated 316L stainless steel wire mesh filters featuring a specific Dutch weave pattern, the refinery achieved finer particle separation (reducing impurities by 15%), extended filter lifespan by 30%, and significantly reduced maintenance downtime, leading to substantial cost savings and improved product quality.

- Municipal Wastewater Treatment: A large urban wastewater treatment plant faced issues with high-solids content clogging their primary screening systems. Implementation of large panels of sturdy stainless steel wire mesh roll with optimized apertures effectively pre-screened incoming water, reducing downstream equipment wear by 20% and improving overall treatment efficiency. The corrosion resistance of the stainless steel ensured long-term performance in a highly aggressive environment.

- Food Processing Sieving System: A leading bakery modernized its flour sieving system. By integrating fine-mesh 304 stainless steel screens, they eliminated contamination risks from foreign particles and achieved more consistent flour granularity, vital for product uniformity. The mesh's hygienic properties and ease of cleaning also simplified compliance with stringent food safety regulations.

These examples demonstrate that the right stainless steel mesh for sale solution, carefully selected and expertly manufactured, is not just a component but a strategic investment that drives operational excellence, enhances product quality, and ensures long-term system reliability. Customer feedback consistently highlights the superior durability and consistent performance when high-grade stainless steel mesh is utilized.

Ensuring Trust and Reliability: Our Commitment

Building trust in the B2B sector for stainless steel wire mesh involves more than just product delivery; it's about consistent quality, transparent processes, and unwavering support. Our commitment to excellence is deeply embedded in every stage, from material sourcing to post-sales service, ensuring that every stainless steel wire mesh product meets the highest industry benchmarks.

- Authoritative Certifications: We operate under strict quality management systems, holding certifications such as ISO 9001:2015, ensuring consistent product quality and adherence to internationally recognized standards. Our products frequently meet or exceed ASTM and ANSI specifications, providing verifiable benchmarks for performance.

- Rigorous Quality Control: Every batch of stainless steel wire mesh undergoes comprehensive testing, including material composition analysis, tensile strength tests, mesh count verification, and visual inspections, documented with detailed test reports available to clients.

- Extensive Service Experience: With over two decades of experience in the wire mesh industry, we have cultivated deep technical expertise and a profound understanding of diverse industrial needs. Our long-standing partnerships with leading companies globally attest to our reliability and service quality.

- Dedicated Customer Support: Our team of technical experts is available to assist with product selection, customization requirements, and troubleshooting, providing prompt and informed responses to ensure optimal solutions for your projects.

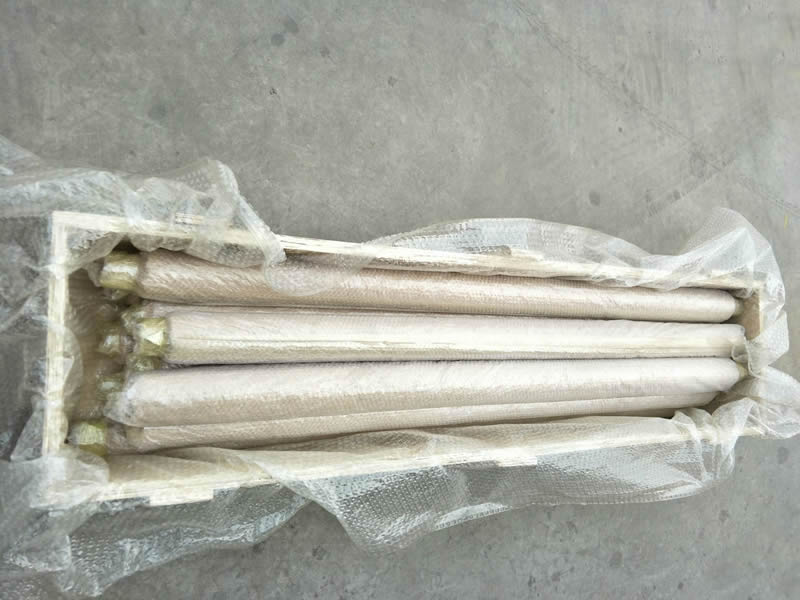

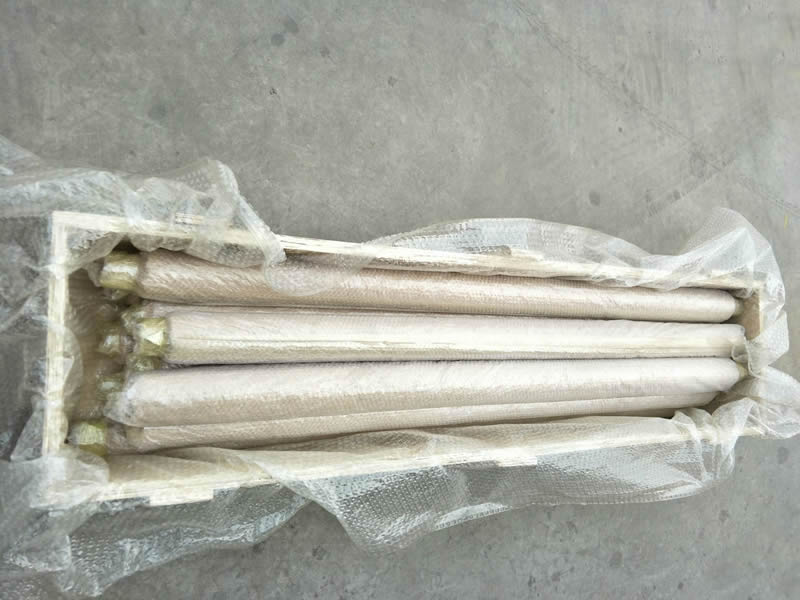

We stand by the quality of our stainless steel mesh for sale with comprehensive warranties, outlining product lifespan and performance guarantees under specified conditions. Our streamlined delivery protocols ensure efficient order processing and timely shipment, minimizing lead times and keeping your projects on schedule. This unwavering commitment to quality and service forms the bedrock of our client relationships.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a custom stainless steel wire mesh order?

- A: Lead times for custom stainless steel wire mesh orders vary depending on the complexity of the specifications, order volume, and current production schedules. Typically, lead times range from 2 to 6 weeks. We provide a detailed estimate upon quotation and communicate proactively throughout the manufacturing process to ensure transparency.

- Q: How do I determine the correct mesh count and wire diameter for my application?

- A: Determining the correct specifications depends on factors such as desired filtration efficiency, flow rate, mechanical strength requirements, and the nature of the material being processed (particle size, viscosity, corrosiveness). Our technical sales team can provide expert consultation based on your specific application and industry standards. Providing sample data or existing filter specifications can greatly assist in this process.

- Q: What is the lifespan of stainless steel wire mesh in a corrosive environment?

- A: The lifespan of stainless steel wire mesh in a corrosive environment largely depends on the specific stainless steel grade (e.g., 304, 316, 316L), the concentration and type of corrosive agents, temperature, and pressure. Generally, 316L offers superior resistance to chloride-induced corrosion and can last significantly longer in aggressive chemical or marine environments compared to 304. Proper selection of the material grade is crucial for maximizing service life.

- Q: Do you offer samples of your stainless steel mesh for sale?

- A: Yes, we understand the importance of evaluating product quality firsthand. We can provide samples of our standard stainless steel wire mesh roll products or small custom cuts for testing purposes. Please contact our sales department to discuss your sample requirements.

Conclusion: Your Trusted Partner for Stainless Steel Wire Mesh Solutions

The demand for robust, reliable, and high-performance stainless steel wire mesh continues to be a cornerstone across industrial sectors. From the intricacies of fine filtration in pharmaceuticals to the heavy-duty screening in mining, the unique combination of corrosion resistance, strength, and versatility offered by stainless steel wire mesh makes it an indispensable material. Choosing the right partner for your stainless steel mesh for sale needs ensures not only superior product quality but also the benefit of extensive technical expertise, customized solutions, and steadfast after-sales support.

As a leading provider, we are dedicated to supplying premium stainless steel wire mesh products that meet the precise demands of your applications. Our commitment to rigorous manufacturing standards, comprehensive quality control, and customer-centric service ensures that you receive a solution that enhances efficiency, reduces operational costs, and delivers lasting value. Explore our range of Stainless Steel Wire Mesh products and let us be your trusted partner in achieving your industrial objectives.

Authoritative References

- ASTM International. "Standard Specification for Industrial Woven Wire Cloth and Screens (Square Opening Series)." ASTM E2016.

- International Organization for Standardization. "Quality management systems — Requirements." ISO 9001.

- Davis, J.R. "ASM Handbook, Vol 1: Properties and Selection: Irons, Steels, and High-Performance Alloys." ASM International.

- American Welding Society. "Welding Handbook, Volume 1: Materials and Applications." AWS.

- NACE International. "Corrosion Basics: An Introduction." NACE Press.