Hit enter to search or ESC to close

High-Quality Chain Link Fence Machine for Sale - Durable & Efficient

The global demand for secure perimeter solutions continues its robust upward trajectory, driving significant innovation and expansion within the wire mesh industry. As infrastructure projects proliferate worldwide, from residential developments and agricultural enclosures to high-security industrial zones and public utilities, the need for efficient and reliable chain link fencing remains paramount. This sustained demand directly influences the market for advanced chain link fence machine for sale. Contemporary trends highlight a shift towards machines that offer not only increased production speed but also enhanced versatility, automation, and energy efficiency. Manufacturers are increasingly seeking solutions that can process a wider range of wire gauges and mesh sizes, while minimizing operational costs and labor requirements. The integration of smart technologies, such as IoT-enabled monitoring and predictive maintenance, is also gaining traction, promising higher uptime and optimized resource utilization. This technological evolution is critical for businesses aiming to maintain a competitive edge and meet the escalating market expectations for durable, cost-effective fencing solutions. The market is also witnessing a growing preference for eco-friendly manufacturing processes and machines that contribute to sustainable production, aligning with global environmental regulations and corporate social responsibility initiatives. Businesses investing in modern chain link weaving machine for sale are positioned to capitalize on these trends, delivering superior products with improved efficiency.

Furthermore, the diversification of application scenarios necessitates machines capable of producing specialized fencing, including anti-climb, high-security, and decorative options. This requires machines with precise control over weaving patterns and tension. The economic landscape, characterized by fluctuating raw material prices and increasing labor costs, further compels producers to invest in highly automated and material-efficient chain link machine for sale. Supply chain resilience, post-pandemic, has also become a critical factor, with buyers prioritizing suppliers who can offer reliable delivery times and comprehensive after-sales support. This market dynamic underscores the importance of not just the machine's technical specifications, but also the total cost of ownership and the long-term support provided by the manufacturer. Emerging markets, particularly in Asia and Africa, represent significant growth opportunities, with large-scale infrastructure projects driving substantial procurement of fencing materials and, consequently, the machinery required for their production. Understanding these intricate market dynamics is crucial for any enterprise considering an investment in a modern chain link fence machine for sale, ensuring that their acquisition aligns perfectly with current and future industry demands and enables maximum return on investment. The focus is increasingly on robust, adaptable machinery that can deliver consistent quality under continuous operation, proving essential for both small-scale operations and large industrial producers alike.

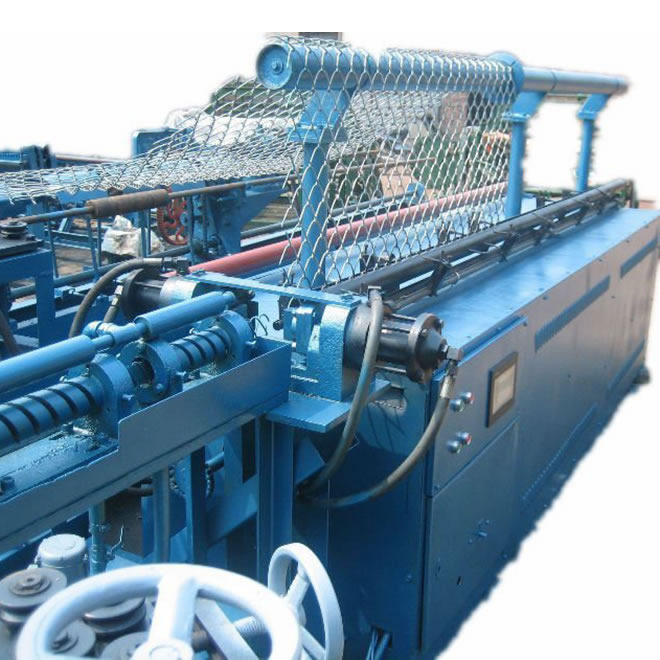

A modern chain link fence machine for sale is a sophisticated piece of industrial equipment designed for the automated production of woven wire mesh. At its core, the machine typically comprises several key components working in concert: a wire feeding system, a weaving head, a cutting mechanism, and a rolling or coiling unit. The wire feeding system precisely delivers galvanized or PVC-coated wire from spools into the machine. The weaving head, often utilizing a single or double spiral mechanism, intricately interlocks the wires to form the characteristic diamond pattern. Precision engineering ensures that each weave is consistent, maintaining the structural integrity and aesthetic uniformity of the fence. Once the desired mesh width is achieved, an automated cutting mechanism severs the woven fabric, and the finished product is then automatically rolled into compact bundles or coils, ready for transport and installation. The level of automation varies significantly across models, from semi-automatic machines requiring more operator intervention to fully automatic systems capable of continuous, unattended operation, which are highly sought after in the current market.

Several types of chain link fence machine for sale cater to diverse production needs. The single wire type is simpler, using one wire to form the mesh, suitable for smaller operations or specific mesh sizes. In contrast, the double wire or dual-feed type machine significantly boosts productivity by simultaneously weaving two wires, effectively doubling the output rate for certain configurations. Advanced models often feature PLC (Programmable Logic Controller) systems for precise control over weaving parameters, including mesh size, wire gauge, and production speed, allowing for quick adjustments and minimal downtime. Integration of frequency converters ensures energy efficiency by optimizing motor speeds according to the load. Furthermore, some machines incorporate automatic edge twisting or knotting mechanisms, providing a secure and aesthetically pleasing finish to the fence rolls. Understanding these mechanical intricacies and available configurations is paramount for potential buyers, as it directly impacts production capacity, operational efficiency, and the quality of the final product. The choice between machine types often depends on projected production volume, budget constraints, and the specific market demands for different types of chain link fencing.

The manufacturing process of a robust chain link fence machine for sale exemplifies precision engineering, ensuring durability and high performance. It begins with the meticulous selection of high-grade raw materials. Key structural components, such as the machine frame and critical moving parts, are typically fabricated from heavy-duty steel alloys, often Q235B or Q345B, renowned for their excellent tensile strength and fatigue resistance. These materials undergo rigorous quality checks upon arrival, including spectrographic analysis to confirm chemical composition and ultrasonic testing for internal defects. The manufacturing process itself involves a combination of advanced techniques. Large structural elements are often fabricated through precision cutting and welding, ensuring dimensional accuracy and robust joints. Smaller, intricate components, especially those requiring high wear resistance or precise tolerances, are often produced using CNC (Computer Numerical Control) machining. This allows for unparalleled accuracy, repeatability, and efficiency in shaping complex parts like weaving mandrels, gears, and wire guides. Surface treatments, such as powder coating or chrome plating, are applied to critical components to enhance their corrosion resistance and extend their operational lifespan, particularly important in demanding industrial environments where such machines operate continuously.

Each stage of the manufacturing process adheres to stringent quality control protocols, reflecting international standards such as ISO 9001 for quality management systems and ANSI standards for mechanical integrity. Key inspection points include dimensional verification of all machined parts, material hardness testing, and weld integrity checks using non-destructive testing (NDT) methods. Before assembly, all electrical components are tested for conformity to IEC (International Electrotechnical Commission) standards, ensuring operational safety and reliability. Post-assembly, every chain link fence machine for sale undergoes a comprehensive series of functional tests, including continuous run tests under various load conditions to simulate real-world production. This ensures consistent performance, optimal wire feeding, precise weaving, and accurate cutting. For instance, a machine might be tested for 72 hours of continuous operation at its maximum rated speed to verify stability and durability. The typical service life of a well-maintained industrial-grade chain link machine can exceed 15-20 years, depending on usage intensity and maintenance regimen. These robust manufacturing and testing procedures ensure that each machine delivered meets the highest benchmarks for quality, reliability, and longevity, providing a foundational asset for industries from petrochemical to metallurgy and public infrastructure, where consistent fence quality and production uptime are critical.

Investing in a chain link fence machine for sale requires a thorough understanding of its technical specifications, which directly correlate with its performance, efficiency, and suitability for specific production demands. Key parameters include the wire diameter range, mesh opening size, maximum fence width, and production capacity. A typical industrial machine might handle wire diameters from 2.0 mm to 4.0 mm (14-8 SWG), accommodating various fencing requirements from light residential use to heavy-duty industrial security. The mesh opening, typically measured diagonally, can range from 25x25mm up to 100x100mm, offering versatility for different applications. Maximum fence width is a crucial factor, with standard machines capable of producing rolls up to 4 meters wide, while specialized models can achieve wider outputs for large-scale projects. Production capacity, often expressed in square meters per hour, is a critical performance indicator, with advanced double-wire machines capable of exceeding 150-200 square meters per hour, significantly enhancing productivity compared to older models. Energy consumption is another vital metric; modern machines often incorporate variable frequency drives (VFDs) and high-efficiency motors, reducing power usage by up to 20-30% compared to conventional systems, translating into substantial operational cost savings.

Beyond these primary specifications, secondary metrics like the machine's overall dimensions, weight, and installed power (kW) are important for facility planning and installation. Noise levels and safety features, such as emergency stops, safety guards, and interlocking mechanisms, comply with international industrial safety standards, ensuring a secure working environment. The type of raw material processed – typically galvanized steel wire, PVC coated wire, or stainless steel wire – also influences machine design and component selection. For example, machines processing PVC-coated wire require specialized guides to prevent scratching the coating. The level of automation, from semi-automatic to fully automatic with automatic mesh rolling and edge finishing, dictates labor requirements and overall efficiency. The integration of advanced diagnostics and remote monitoring capabilities further enhances the operational efficiency and predictive maintenance schedules. Below is a comparative table illustrating typical parameters for different classes of chain link fence machine for sale, providing a clear benchmark for decision-making. These parameters underscore the machine's capacity to deliver consistent quality and high output, essential for meeting diverse market needs in sectors like construction, agriculture, and public safety.

| Parameter | Entry-Level (Semi-Auto) | Mid-Range (Full-Auto Single Wire) | High-End (Full-Auto Double Wire) |

|---|---|---|---|

| Wire Diameter Range | 2.0mm - 4.0mm | 2.0mm - 5.0mm | 1.8mm - 6.0mm |

| Mesh Opening (Diagonal) | 50x50mm - 100x100mm | 40x40mm - 100x100mm | 25x25mm - 100x100mm |

| Max Fence Width | 3.0 meters | 4.0 meters | 6.0 meters |

| Production Capacity (m²/hr) | Up to 80 | 100 - 150 | 150 - 220+ |

| Installed Power | 5-7 kW | 9-12 kW | 15-20 kW |

| Control System | Manual/Basic PLC | Advanced PLC | PLC with HMI Touchscreen |

The ubiquitous nature of chain link fencing is a testament to its unparalleled versatility and cost-effectiveness, making machines that produce them, like the chain link fence machine for sale, essential assets across a myriad of industries. In the residential and commercial sectors, chain link fences are widely used for securing property boundaries, playgrounds, sports courts (tennis courts, baseball fields), and temporary construction sites. Their open weave allows for visibility while providing a clear physical barrier. For instance, a sports complex benefits from the durability and low maintenance of chain link, which can withstand significant impact from sports activities and varying weather conditions. In agricultural applications, chain link is invaluable for livestock containment, protecting crops from wildlife, and delineating farm boundaries. Its flexibility allows for adaptation to uneven terrain, and its robust construction ensures long-term protection against animal breaches. The ease of installation and relatively low material cost make it a preferred choice for large-scale agricultural projects seeking efficient fencing solutions.

The demand for reliable chain link machine for sale also stems from its critical role in industrial and infrastructural projects. In petrochemical facilities, secure perimeters are non-negotiable for safety and regulatory compliance. Chain link fencing, often coupled with barbed wire or razor wire, provides an effective first line of defense. Its open design also facilitates visual surveillance, crucial for monitoring large industrial complexes. Similarly, in the metallurgy sector and mining operations, robust fencing is required to secure hazardous areas, equipment, and raw material stockpiles. The corrosion-resistant properties of galvanized or PVC-coated chain link make it ideal for environments exposed to chemicals or harsh weather. For public utilities and water supply/drainage systems, chain link fences protect critical infrastructure like reservoirs, pumping stations, and electrical substations from unauthorized access and vandalism. In these scenarios, the fence's ability to be customized for height, wire gauge, and anti-climb features, directly produced by a versatile chain link weaving machine for sale, offers significant advantages. Furthermore, the inherent design allows for excellent wind permeability, reducing structural stress in high-wind areas, and its modular nature simplifies repairs and expansions. These diverse applications underscore the fundamental utility and enduring demand for high-quality chain link fencing, affirming the value of investing in efficient production machinery.

The latest generation of chain link fence machine for sale offers a suite of advanced features and technical advantages that significantly enhance productivity, operational efficiency, and product quality. One major advancement is the implementation of fully automatic operation, from wire feeding and weaving to cutting, rolling, and even edge finishing. This minimizes manual intervention, drastically reducing labor costs and human error, while maximizing continuous production uptime. Precision components, often manufactured through CNC machining, ensure superior mechanical performance and extended lifespan. For instance, hardened alloy steel molds and cutters resist wear even under high-speed operation, maintaining precise mesh dimensions over millions of cycles. Integrated hydraulic or pneumatic systems provide smooth, powerful, and controlled movements for weaving heads and cutting mechanisms, contributing to both speed and accuracy. The ability to handle various wire materials—from galvanized steel to vinyl-coated wires—without extensive retooling is another significant advantage, offering manufacturers the flexibility to meet diverse market demands with a single machine.

Energy efficiency is a paramount consideration for modern industrial machinery. Contemporary chain link weaving machine for sale models incorporate highly efficient servo motors and variable frequency drives (VFDs) that precisely control power consumption based on load, leading to substantial energy savings—up to 25% compared to older, fixed-speed motor systems. This not only reduces operational expenses but also contributes to a lower carbon footprint. Automation extends to fault detection and troubleshooting; sophisticated sensor arrays and PLC diagnostics can identify issues quickly, minimizing downtime and simplifying maintenance. Some high-end models even offer remote monitoring and diagnostic capabilities via IoT (Internet of Things) platforms, allowing operators and technicians to oversee machine performance from anywhere and predict potential failures before they occur. The integration of intuitive HMI (Human-Machine Interface) touchscreens simplifies operation and parameter adjustments, making the machines user-friendly even for less experienced operators. These technical advantages translate into higher yield rates, reduced waste, superior product consistency, and a faster return on investment for businesses seeking a competitive edge in the chain link fencing market.

Selecting the right chain link fence machine for sale is a strategic decision that goes beyond initial purchase price, requiring a comprehensive evaluation of manufacturers and their capabilities. Reputable manufacturers distinguish themselves through adherence to international quality standards such as ISO 9001:2015, extensive R&D investment, and a proven track record of customer satisfaction. When comparing potential suppliers, consider factors like the company's service history and years in the industry, which often correlate with accumulated expertise and reliability. Look for manufacturers that openly provide performance data, test certificates, and client testimonials. While some manufacturers might offer slightly lower initial costs, scrutinize the build quality, component sourcing (e.g., using globally recognized brands for motors, PLCs), and the availability of spare parts. A robust after-sales service network, including technical support, training, and prompt spare parts delivery, is crucial for minimizing potential downtime and ensuring long-term operational success. Furthermore, assessing a manufacturer's capacity for customization is vital for businesses with unique production requirements.

Customization options for a chain link machine for sale can significantly enhance its utility and efficiency for specific operational contexts. These can range from minor adjustments to complete bespoke designs. Common customization requests include modifications to the maximum fence width or height to accommodate oversized projects, specialized weaving heads for producing unique mesh patterns or smaller mesh openings, and integration with existing factory automation systems. For example, some clients may require machines adapted to handle non-standard wire gauges or materials, such as specific grades of stainless steel, necessitating specialized wire feeding and tensioning mechanisms. Energy-saving features, specific electrical configurations to match local power grids, and advanced safety interlocks conforming to particular regional regulations are also frequently requested customizations. A truly customer-centric manufacturer will offer a consultation process, involving detailed technical discussions and feasibility studies, to ensure the customized solution perfectly aligns with the client's production goals and operational environment. This collaborative approach minimizes risks and maximizes the return on investment, solidifying the manufacturer as a trusted partner rather than just a supplier of a chain link fence machine for sale.

The true measure of a chain link fence machine for sale's effectiveness lies in its real-world performance and the success stories of its users. Consider a recent case study involving a major fencing contractor in the Middle East. Faced with escalating demand for high-security perimeter solutions for oil and gas facilities, they invested in a high-speed, fully automatic chain link weaving machine. Prior to this acquisition, their production capacity was a bottleneck, relying on older, semi-automatic models. Post-installation, the new machine, featuring dual-wire feed and an integrated automatic rolling system, boosted their daily output by over 70%, enabling them to meet aggressive project deadlines and take on larger contracts. The client reported a significant reduction in labor costs due to the machine's automation, and the consistent mesh quality, maintained by its precision control system, led to fewer material rejections and enhanced client satisfaction. This tangible return on investment underscored the machine's technical superiority and its direct impact on business growth, solidifying its standing as a premier chain link fence machine for sale.

Another compelling example comes from an agricultural fencing supplier in North America who needed a versatile chain link machine for sale to produce various mesh sizes for diverse farm applications, from poultry enclosures to cattle fencing. They opted for a model known for its quick changeover capabilities between different mesh specifications. The feedback highlighted the machine's intuitive HMI, which simplified operator training and reduced setup times by 50%. This flexibility allowed them to efficiently process custom orders, enhancing their competitive edge in a niche market. Furthermore, a long-term client, an established construction material supplier in Europe, has been operating one of our chain link fence machine for sale models for over a decade. Their primary feedback consistently emphasizes the machine's extraordinary durability and minimal maintenance requirements, attributing these qualities to the robust construction and high-quality components. "The machine has been a workhorse," stated their production manager, "delivering consistent, high-quality output year after year with very few interruptions. It has truly been a cornerstone of our fencing division's success." These testimonials and practical application results collectively demonstrate the reliability, efficiency, and long-term value that modern chain link fence machines provide to diverse industries globally.

Building trust with B2B clients who are considering a significant investment in a chain link fence machine for sale is paramount. Transparency regarding support, logistics, and long-term commitments is key. Our commitment to client satisfaction extends beyond the sale, encompassing comprehensive support throughout the machine's lifecycle.

Our streamlined logistics ensure efficient and secure delivery of your chain link fence machine for sale. Once manufactured and rigorously tested, machines are carefully packed for international transit, utilizing robust wooden crates or steel frames to prevent damage. We partner with reputable global freight forwarders to provide both sea and air freight options, offering DDP (Delivered Duty Paid), DAP (Delivered At Place), or FOB (Free On Board) terms as per client preference. A dedicated logistics team monitors shipments in real-time and provides regular updates, ensuring transparency and peace of mind from our factory to your facility. Typical sea freight transit times range from 3-6 weeks depending on destination, while air freight is available for urgent requirements.

Every chain link fence machine for sale comes with a comprehensive warranty, typically covering 12 to 24 months from the date of commissioning or shipment, whichever comes first, against manufacturing defects and component failures under normal operating conditions. Our dedicated customer support team provides multi-channel assistance, including phone, email, and video conferencing, ensuring that technical queries are resolved swiftly. We also offer optional extended warranty programs and preventative maintenance contracts to ensure the long-term optimal performance of your investment. Our commitment is to provide unparalleled service, ensuring maximum uptime and profitability for your chain link fence production operations.

This is the last article

JOIN OUR NEWSLETTER

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.