Hit enter to search or ESC to close

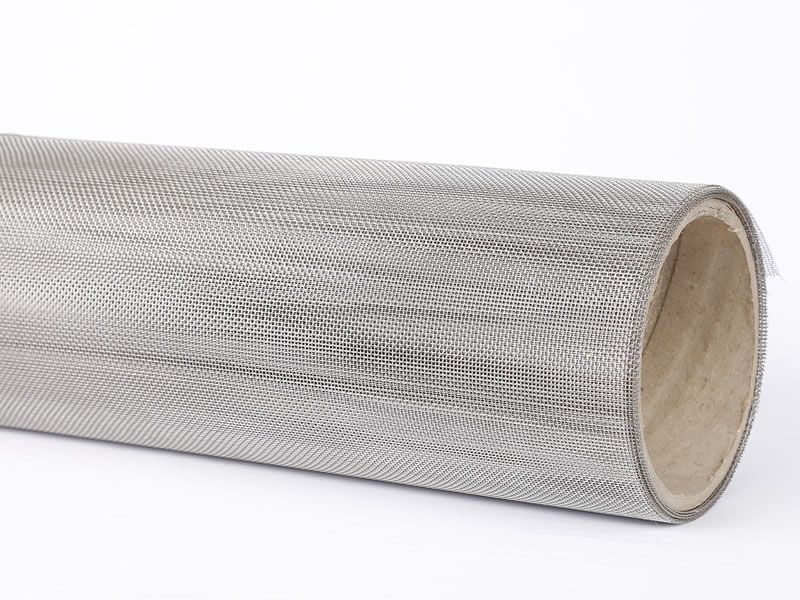

Stainless Steel Mesh For Sale - Quality Wire Mesh Rolls

In today's diverse industrial landscape, the demand for high-performance filtration, separation, and structural reinforcement solutions is ever-increasing. Among the myriad of materials available, stainless steel mesh for sale stands out as a superior choice, renowned for its unparalleled corrosion resistance, high tensile strength, and exceptional longevity. This material's intrinsic properties make it indispensable across a spectrum of critical applications, from intricate filtration processes in pharmaceutical manufacturing to robust architectural elements demanding aesthetic appeal and structural integrity. Understanding the nuances of stainless steel mesh begins with appreciating its fundamental composition: primarily iron, chromium (at least 10.5%), and often nickel, molybdenum, or other alloying elements. The chromium content forms a passive, self-repairing oxide layer on the surface, which is the secret behind its remarkable resistance to rust and staining. This passive layer, typically a few nanometers thick, provides a formidable barrier against aggressive chemical agents, extreme temperatures, and abrasive environments, ensuring operational stability and extended service life. The versatility extends to its various forms, including woven, welded, and expanded meshes, each offering distinct advantages in terms of aperture size, strength-to-weight ratio, and flow characteristics. Selecting the appropriate mesh requires a comprehensive understanding of specific application demands, including required filtration precision, load-bearing capacity, and environmental exposure to ensure optimal performance. The market for stainless steel mesh is characterized by continuous innovation, driven by advancements in material science and manufacturing technologies, leading to products with enhanced performance attributes and expanded utility. This initial exploration sets the stage for a deeper dive into its manufacturing processes, technical specifications, and widespread industrial applications, providing a holistic perspective for B2B decision-makers seeking reliable and cost-effective material solutions that promise long-term returns on investment.

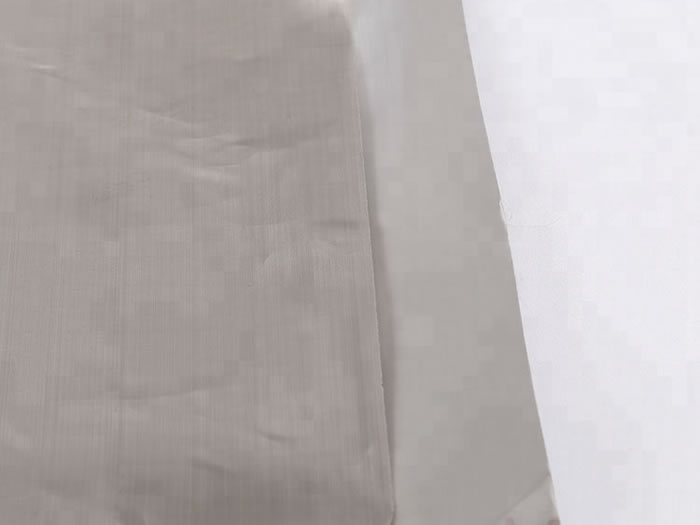

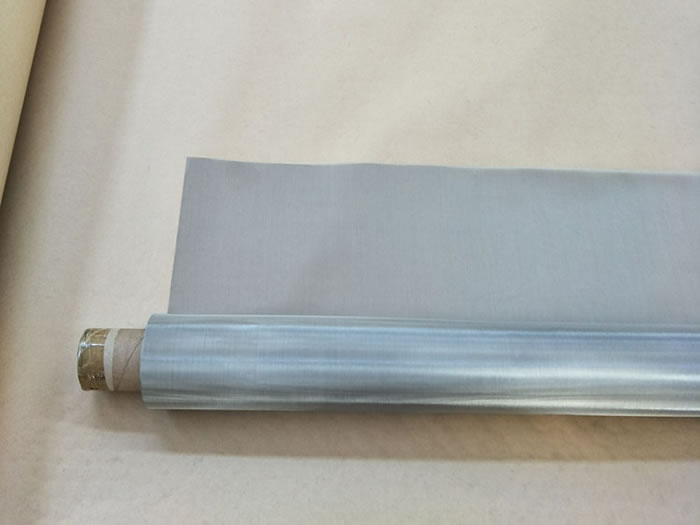

The production of high-quality stainless steel wire mesh involves a sophisticated multi-stage process, meticulously controlled to ensure adherence to stringent industry standards such as ISO 9001:2015 for quality management systems and ASTM E2016-11 for woven wire mesh specifications. The journey begins with the selection of premium-grade stainless steel wire, typically AISI 304, 304L, 316, or 316L, chosen specifically for its intended application's corrosion resistance and mechanical properties. AISI 304 offers excellent general-purpose corrosion resistance, making it suitable for a wide range of environments, while 316L, with its added molybdenum content, provides superior resistance to pitting and crevice corrosion, particularly vital in chloride-rich environments like marine, pharmaceutical, or chemical processing applications. Once the raw wire coils are drawn to the precise diameter, often ranging from an ultra-fine 0.02mm to a robust 6.0mm, they undergo a crucial weaving or welding phase. Woven mesh production utilizes highly specialized looms where warp wires (longitudinal) and weft wires (transverse) are intricately interlaced to form various patterns: plain weave for robust, simple structures; twill weave for increased wire density and finer filtration capabilities; or Dutch weave, which creates small, intricate pores for highly precise particle separation. For welded mesh, individual wires are resistance-welded at each intersection, forming a rigid, dimensionally stable grid ideal for security fencing, concrete reinforcement, or machine guards. Post-weaving or welding, the mesh may undergo further treatment, including thorough cleaning, annealing to relieve internal stresses and enhance ductility, and passivation. Passivation is a critical chemical process where free iron on the surface is removed, allowing the chromium to form a stronger, more uniform passive oxide layer, significantly boosting inherent corrosion resistance and ensuring the long-term integrity of the stainless steel wire mesh. Each batch undergoes rigorous quality control, encompassing visual inspection, precise mesh count verification, accurate wire diameter measurement, comprehensive tensile strength testing, and precise aperture size analysis, ensuring every roll meets exact specifications and performance criteria for its intended, demanding application.

Understanding the technical parameters of stainless steel mesh for sale is crucial for specifying the correct product for any industrial requirement, ensuring optimal performance and longevity. Key metrics include mesh count, wire diameter, aperture size (opening), weave pattern, material grade, and roll or sheet dimensions. Mesh count, defined as the number of wires or openings per linear inch, directly correlates with filtration precision; a higher mesh count indicates smaller, finer openings suitable for ultra-fine particle separation (e.g., 600 mesh for sub-25 micron filtration), while a lower count (e.g., 2 mesh) allows for greater flow rates and larger particle retention in coarse screening applications. Wire diameter, measured in millimeters or inches, dictates the mesh's overall strength and rigidity, directly influencing its load-bearing capacity and resistance to deformation under dynamic pressure or heavy loads. The aperture size, or open area, is a critical derived metric calculated based on mesh count and wire diameter, determining the precise size of particles that can pass through the mesh, which is paramount for accurate filtration and screening applications. Weave patterns, such as plain, twill, or various Dutch weaves, significantly impact the mesh's open area percentage, strength characteristics, and flow dynamics. Material grade (e.g., SS304, SS304L, SS316, SS316L, or even more specialized alloys like Duplex stainless steels for extreme conditions) is paramount for chemical compatibility and corrosion resistance, dictating the mesh's suitability for specific, often aggressive, environments, including exposure to strong acids, alkalis, or highly saline solutions. For example, in petrochemical applications dealing with aggressive hydrocarbons or corrosive gases at elevated temperatures, SS316L or Duplex SS are often preferred due to their enhanced resistance to intergranular corrosion and pitting. Standard roll dimensions typically range from 30 meters to 100 meters in length, with widths from 0.914 meters (36 inches) to 1.5 meters (60 inches), though custom dimensions are widely available to meet bespoke project requirements. Operating temperature ranges, tensile strength, and burst pressure are also critical performance indicators, ensuring the mesh can withstand operational stresses and maintain structural integrity over its expected, often multi-decade, lifespan. Below is a detailed table outlining typical parameters for various applications, offering a tangible reference for B2B procurement professionals.

| Parameter | Range/Value | Typical Application |

|---|---|---|

| Material Grade | SS304, SS304L, SS316, SS316L (Duplex, Super Duplex for extreme cases) | General filtration, chemical processing, marine environments, high-stress applications |

| Mesh Count | 2 mesh (10mm opening) to 635 mesh (20 microns opening) per inch | Coarse screening for aggregates to ultra-fine filtration for pharmaceuticals |

| Wire Diameter | 0.02 mm to 6.0 mm (0.0008 inches to 0.236 inches) | Dictates mesh strength, rigidity, and open area control; critical for load bearing |

| Aperture Size | 20 microns to 12.7 mm (0.0008 inches to 0.5 inches) | Determines precise particle separation and flow characteristics |

| Weave Pattern | Plain, Twill, Dutch, Reverse Dutch, Five-Heddle, Intercrimp | Influences flow rate, strength, filtration efficiency, and stability |

| Open Area | Approx. 20% to 75% (highly variable by weave/mesh count) | Directly impacts throughput capacity and screening efficiency |

| Temperature Range | Up to 800°C (1472°F) for SS304/316, higher for specialized alloys | High-temperature processes, furnace components, heat treatment applications |

| Tensile Strength | Typically 520-620 MPa for SS304; higher for specific hardened grades | Ensures structural integrity, load-bearing capacity, and resistance to rupture |

The adaptability and robust performance of stainless steel wire mesh enable its deployment across an extensive array of industries, each leveraging its unique properties for specific operational advantages and cost efficiencies. In the petrochemical sector, it is vital for catalyst support grids, particulate filtration in refining processes, demister pads to separate liquid droplets from gas streams, and safeguarding critical equipment from corrosive substances. Here, its anti-corrosion properties significantly extend the lifespan of infrastructure and contribute to energy efficiency by maintaining system purity and flow. The mining and metallurgy industries rely heavily on stainless steel mesh for vibratory screen decks used in ore screening and grading, dewatering applications, and as robust protective barriers against harsh abrasive conditions and high-impact forces, with certain weaves specifically designed to withstand severe wear and tear. For sophisticated water treatment and drainage systems, fine mesh screens prevent clogging from debris and particulate matter, ensuring efficient fluid flow, safeguarding sensitive downstream equipment like pumps and valves, and thereby reducing maintenance costs and enhancing overall system reliability. The food and beverage sector benefits immensely from its hygienic properties; stainless steel is non-toxic, non-reactive, easy to sterilize, and resistant to bacterial growth, making it ideal for sieving, drying, conveying food products, and as filter elements in liquid processing lines. Beyond traditional industrial applications, there's a rapidly growing trend in architectural and design uses, where the aesthetic appeal, structural strength, and low maintenance of stainless steel wire mesh roll are harnessed for modern building facades, decorative partitions, balustrade infill panels, security screens, and unique artistic installations, offering both functional benefits and contemporary design elements. Emerging trends include the increasing demand for ultra-fine mesh in advanced filtration technologies, such as microfiltration and nanofiltration, driven by stringent environmental regulations, the growing need for higher purity standards in sensitive processes (e.g., semiconductor manufacturing), and the burgeoning hydrogen economy. The continuous development of specialized alloys like Duplex stainless steel, offering enhanced strength and corrosion resistance in even more extreme environments, further expands the material's utility, showcasing continuous innovation within the industry and solidifying its position as a cornerstone material in modern industrial and commercial development.

The distinct technical advantages of stainless steel mesh for sale are pivotal to its widespread adoption across demanding industrial applications, offering benefits that significantly outweigh conventional materials and directly impact operational efficiency and cost savings. Foremost among these is its superior corrosion resistance, particularly when fabricated from grades like SS316L, which makes it inherently ideal for prolonged exposure to aggressive chemicals, corrosive gases, saltwater, and high humidity, far surpassing the capabilities of galvanized or carbon steel mesh which degrade rapidly in such environments. This inherent resistance to rust, pitting, and crevice corrosion translates directly into an exceptionally extended service life, drastically reducing the frequency of replacements and the associated maintenance labor and material costs, contributing to a demonstrably lower total cost of ownership over the product lifecycle. Furthermore, stainless steel exhibits excellent high-temperature resistance, retaining its structural integrity, mechanical properties, and filtration efficiency even in environments reaching hundreds of degrees Celsius (e.g., up to 800°C for common grades), making it indispensable in furnace components, heat exchangers, and industrial ovens where other materials would fail. Its high tensile strength and ductility allow it to withstand significant mechanical stress, severe vibration, and high-impact forces without deforming, fracturing, or losing its precise mesh opening, ensuring reliable performance in dynamic systems such as conveyor belts, vibrating screens, or high-pressure filters. The material's hygienic properties are another significant advantage; its non-porous surface is non-contaminating, extremely easy to clean and sanitize, and naturally resistant to bacterial growth, making it a preferred and often mandated choice in pharmaceutical, medical, and food processing industries where sterility and product purity are paramount. Moreover, stainless steel is fully recyclable, aligning with modern sustainability goals and offering an environmentally responsible material choice that contributes to a circular economy. Manufacturers often optimize these advantages further through specialized post-treatment processes like electropolishing, which smooths the surface and further enhances corrosion resistance and cleanability, or by applying specialized coatings for specific wear, abrasion, or non-stick properties. These technical attributes collectively contribute to optimizing operational efficiency, ensuring safety, and delivering profound long-term value in critical and demanding industrial processes, proving stainless steel mesh is an investment in reliability.

When sourcing stainless steel wire mesh, discerning manufacturers is absolutely critical for ensuring product quality, reliability, and unparalleled technical support. Reputable suppliers distinguish themselves through unwavering adherence to international quality standards like ASTM, ISO (e.g., ISO 9001:2015), and DIN, robust in-house quality control procedures, and extensive experience serving diverse industry applications globally. A key differentiator that sets leading manufacturers apart lies in their ability to offer bespoke customization solutions, precisely tailoring products to specific client requirements. While standard rolls of stainless steel wire mesh roll are readily available for common applications, many advanced industrial processes and specialized engineering projects demand highly tailored specifications that off-the-shelf products cannot meet. This includes precise control over mesh count, wire diameter, and aperture size to meet exact filtration or screening requirements, which can vary widely from ultra-fine particle separation in high-purity laboratory settings to heavy-duty industrial screening for aggregates. Customization extends to unique weave patterns, such as multi-layer Dutch weaves for enhanced filtration efficiency and pressure resistance, or pleated meshes for significantly increased surface area within compact filter elements. Furthermore, advanced manufacturers can provide specific surface finishes like calendering for a smoother, more uniform surface, electropolishing for dramatically improved corrosion resistance and hygiene in critical environments, or specialized coatings for enhanced abrasion resistance or anti-static properties. Comprehensive fabrication services, including precision cutting, slitting, welding into complex custom shapes (e.g., cylinders, cones, baskets), or forming into specific components, are also crucial for integrating the mesh seamlessly into existing or new systems. For example, a client requiring custom filter baskets for a high-temperature, corrosive chemical reactor would need a manufacturer capable of precision welding and forming SS316L mesh to exact dimensions, ensuring chemical compatibility and structural integrity under operational pressures. Evaluating potential suppliers should involve a thorough review of their certifications, a detailed assessment of their production capabilities and equipment, scrutinizing their technical support and R&D investment, and requesting verified case studies or client testimonials that demonstrate their expertise in similar, complex projects. This meticulous due diligence ensures a strategic partnership that delivers optimal product performance, long-term value, and moves beyond mere transactional purchases to a true collaborative solution for specialized industrial challenges.

The practical effectiveness and superior performance of stainless steel mesh for sale are best exemplified through its successful implementation in various demanding industrial environments where reliability is non-negotiable. Consider a major petrochemical plant that adopted SS316L woven mesh for critical catalyst support grids in their reformer units. Prior to this, conventional carbon steel grids frequently succumbed to rapid corrosion and high-temperature deformation under the aggressive chemical and thermal conditions, leading to frequent, costly downtime and significantly reduced process efficiency. The strategic switch to SS316L mesh, specifically a 10-mesh, 1.0mm wire diameter specification with a plain weave, resulted in a remarkable 40% increase in the average operational lifespan for these grids, extending from a mere 18 months to over 30 months. This directly translated into fewer replacement cycles, reduced maintenance labor, and an overall enhancement of plant productivity and profitability. Another compelling case involves a leading pharmaceutical company utilizing ultra-fine SS304L Dutch weave mesh (e.g., 400x325 mesh with a 25-micron filtration rating) in their fluid bed dryer screens to ensure precise particle size separation of active pharmaceutical ingredients (APIs). This application demands absolute purity, minimal contamination risk, and consistent batch quality. The SS304L mesh's inert, non-reactive surface and exceptional ease of cleaning, combined with its precise and stable aperture control, entirely eliminated contamination issues previously encountered with alternative filter media, leading to a measurable 15% improvement in product yield and consistent adherence to stringent GMP (Good Manufacturing Practice) standards. In the architectural sector, a large-scale urban development project in a coastal city utilized SS316 architectural mesh for its exterior cladding and solar shading systems. This specialized mesh, featuring a larger wire diameter (e.g., 2.0mm) and a specific cable mesh weave pattern, provided excellent passive solar shading, reduced the building's energy consumption for cooling by an estimated 10-12% annually, and offered a durable, low-maintenance facade with high aesthetic appeal that resisted saltwater corrosion. These diverse, real-world examples underscore not only the technical prowess of stainless steel mesh but also its tangible economic and operational benefits, demonstrating how strategic material selection leads to long-term performance, efficiency gains, and enhanced safety across a multitude of critical industrial and commercial applications.

Building and maintaining trust with B2B clients in the procurement of stainless steel wire mesh is paramount, extending far beyond just product quality to encompass comprehensive support and clear, transparent commitments. Transparency in frequently asked questions (FAQs), reliable delivery logistics, and robust warranty provisions are crucial elements that foster long-term partnerships. Common FAQs often revolve around critical technical considerations such as optimal material compatibility for specific chemical environments (e.g., which grade of stainless steel is best for sulfuric acid exposure), the ideal mesh configuration for desired flow rates or filtration precision (e.g., plain vs. Dutch weave for specific micron ratings), and the full range of customization options available for unique project demands. For instance, clients frequently inquire about the performance difference between SS304 and SS316L for saltwater or marine applications, requiring expert guidance that confirms SS316L's superior resistance due to its molybdenum content and enhanced resistance to pitting and crevice corrosion. Delivery timelines are often a critical factor for industrial projects, directly impacting production schedules and project completion. Reputable suppliers provide clear, realistic lead times based on product specifications, order quantity, current production schedules, and raw material availability. While standard products like a stainless steel wire mesh roll in common sizes might have a lead time of 1-2 weeks for dispatch, highly customized or large-volume orders could range from 4-8 weeks, depending on complexity and raw material sourcing. Effective inventory management, coupled with robust logistics networks and reliable shipping partners, ensures timely and secure delivery globally, minimizing project delays. Furthermore, a clear, comprehensive, and accessible warranty policy underscores a manufacturer's confidence in their product and their commitment to client satisfaction. Typically, this includes a warranty against manufacturing defects and material flaws for a specified period, ranging from 1 to 5 years, depending on the application and product type. This commitment provides financial assurance and protects the client's significant investment. Beyond these formal assurances, responsive customer support – offering prompt technical advice, troubleshooting, and efficient post-sales service – reinforces trustworthiness, demonstrating a genuine, long-term partnership approach that extends beyond the initial transaction, solidifying confidence in the supplier.

While various materials are available for filtration, screening, and structural applications, a direct and comprehensive comparison highlights why stainless steel mesh for sale consistently emerges as the superior and most cost-effective choice for demanding industrial environments over its lifecycle. Common alternative competitors include galvanized steel mesh, carbon steel mesh, various plastic (polymer) meshes, and occasionally more exotic, highly specialized alloys like Inconel or Monel for exceptionally extreme, niche conditions. Galvanized steel mesh, while offering a lower initial procurement cost, relies on a sacrificial zinc coating for corrosion protection. This coating is inherently susceptible to mechanical damage from abrasion, impact, or aggressive chemical exposure, leading to rapid rust formation once compromised, especially in humid or corrosive environments. Its operational lifespan is significantly shorter compared to stainless steel, inevitably resulting in higher long-term replacement frequency and associated maintenance expenses, negating initial cost savings. Carbon steel mesh, although possessing high tensile strength, completely lacks inherent corrosion resistance and rapidly degrades through oxidation (rusting) in any humid or wet conditions, making it unsuitable for most industrial filtration, outdoor, or wet processing applications without extensive, costly protective coatings that themselves require periodic reapplication. Plastic meshes, typically manufactured from PVC, polyethylene (PE), or polypropylene (PP), are lightweight and resistant to some specific chemicals, but they possess significantly lower tensile strength, poor high-temperature resistance, and are prone to degradation from UV radiation, creep deformation under sustained load, and abrasion. This severely limits their use to less demanding, often temporary, or very specific low-stress applications. Stainless steel, by contrast, offers an unparalleled, optimal balance of exceptional inherent corrosion resistance, high tensile strength even at elevated temperatures, excellent temperature stability (retaining mechanical properties across a wide range), and a demonstrably long service life, even in the harshest conditions. While its initial procurement cost might be marginally higher than galvanized or plastic options, its inherent durability, minimal maintenance requirements, and reliable, uninterrupted performance translate into a demonstrably lower total cost of ownership (TCO) and superior operational efficiency over the product's extended lifespan. For critical applications demanding unwavering performance, safety, and long-term economic viability, the strategic investment in stainless steel wire mesh is justified by its unparalleled technical advantages and long-term economic benefits, ensuring system integrity and uninterrupted operations without compromise.

| Feature | Stainless Steel Mesh | Galvanized Steel Mesh | Plastic Mesh (PP/PE) |

|---|---|---|---|

| Corrosion Resistance | Excellent (inherent passivity, self-repairing) | Good (zinc coating, but prone to damage/flaking) | Good (specific chemical resistance, but not universal) |

| Tensile Strength | Very High (retains strength at high temps) | High (strength degrades if coating fails) | Low to Moderate (creep and elongation issues) |

| Temperature Resistance | Excellent (up to 800°C+ without degradation) | Moderate (zinc melts at ~419°C, coating failure) | Poor (typically |

| Service Life | Very Long (decades, minimal degradation) | Moderate (5-10 years, coating dependent) | Short to Moderate (1-5 years, UV/chemical degradation) |

| Maintenance Req. | Very Low (inherent resistance, easy cleanability) | Moderate (coating degradation, rust risk) | Low (but frequent replacement due to wear/degradation) |

| Initial Cost | Moderate to High (reflects material quality & longevity) | Low | Very Low |

| Lifecycle Cost (TCO) | Low (due to longevity, minimal maintenance, reliability) | Moderate to High (due to frequent replacement/maintenance) | High (due to frequent replacement and performance limitations) |

This is the last article

JOIN OUR NEWSLETTER

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.