Hit enter to search or ESC to close

Strong Security Window Screens & Mesh for Home Safety

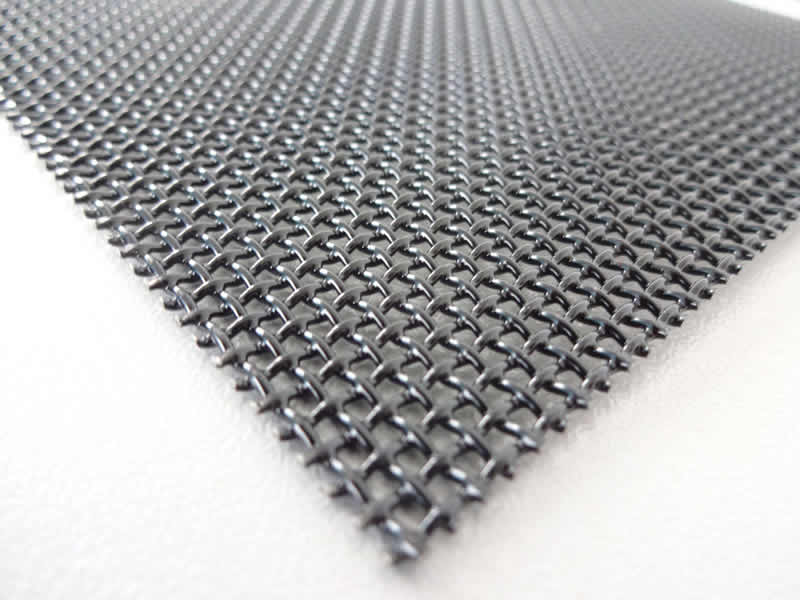

In an era where robust asset protection and occupant safety are paramount, the demand for sophisticated security solutions has never been higher, particularly within the B2B sector. Among these critical solutions, the security window screen stands out as an indispensable component, offering an unparalleled blend of physical deterrence, aesthetic integration, and environmental adaptability. These advanced screens are engineered not merely as barriers but as integral layers of a comprehensive security infrastructure, designed to withstand forced entry attempts, mitigate impacts, and often provide additional benefits such as insect exclusion, UV radiation reduction, and enhanced airflow. Unlike conventional meshes, a security window screen is typically fabricated from high-tensile stainless steel wire, meticulously woven or perforated to create a formidable shield. This specialized construction ensures exceptional resistance to cutting, tearing, and outward pressure, making them suitable for a diverse range of high-stakes environments from critical infrastructure and financial institutions to secure residential complexes and industrial facilities. The strategic implementation of these screens reflects a proactive approach to risk management, safeguarding valuable assets and personnel against both opportunistic and determined threats. Their design philosophy centers on achieving maximum protection without compromising the building’s architectural integrity or its occupants' comfort and visual access, thereby merging high-level security with practical functionality. This introductory overview sets the stage for a deeper exploration into the technological intricacies, strategic advantages, and diverse applications of these essential security components, highlighting their pivotal role in modern security frameworks.

The market for security window screen solutions is undergoing significant transformation, driven by evolving security threats, advancements in material science, and increasing demands for sustainable and intelligent building components. One prominent trend is the shift towards integrating smart technologies, such as embedded sensors that can detect tampering or forced entry attempts and trigger immediate alerts to centralized security systems. This convergence of physical security with digital intelligence enhances response times and provides a more proactive defense posture. Furthermore, there is a growing emphasis on sustainability, leading manufacturers to develop screens with improved energy efficiency, often incorporating features that reduce solar heat gain and minimize the need for air conditioning, aligning with green building initiatives. The raw materials themselves are also evolving; while high-grade stainless steel remains standard, research into composite materials and advanced coatings is exploring ways to enhance strength-to-weight ratios and improve corrosion resistance in extreme environments. For instance, the demand for security window screen mesh with enhanced ballistic resistance or fire-retardant properties is increasing in specialized applications like government buildings or industrial facilities handling flammable materials. The aesthetic integration of these screens is also a key trend, with design innovations allowing for slimmer profiles, customizable finishes, and virtually invisible installations that do not detract from a building's architectural vision. This market evolution reflects a comprehensive approach to security that considers not only brute-force protection but also environmental impact, technological sophistication, and seamless architectural incorporation, ensuring that modern security doors and windows offer multifaceted benefits beyond mere intrusion prevention. As the global security landscape continues to evolve, manufacturers are continually pushing the boundaries of innovation to meet increasingly complex demands, providing solutions that are robust, intelligent, and environmentally conscious.

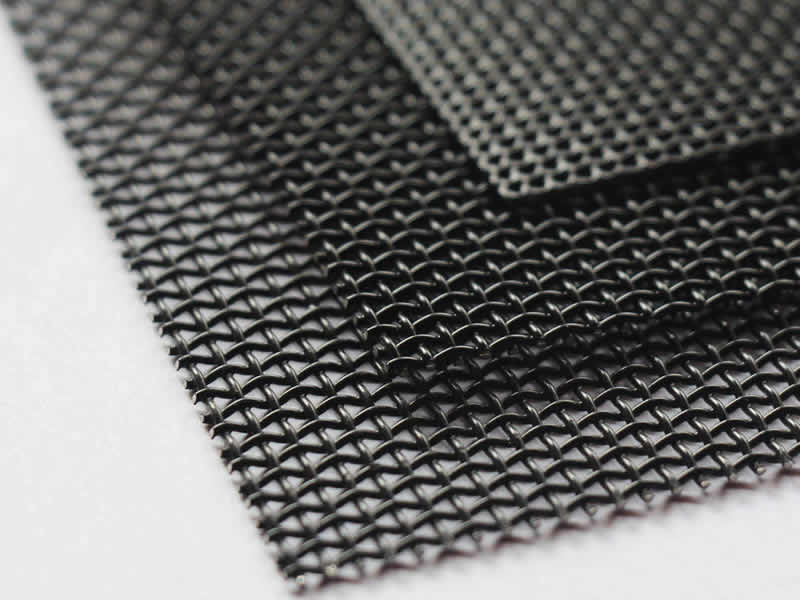

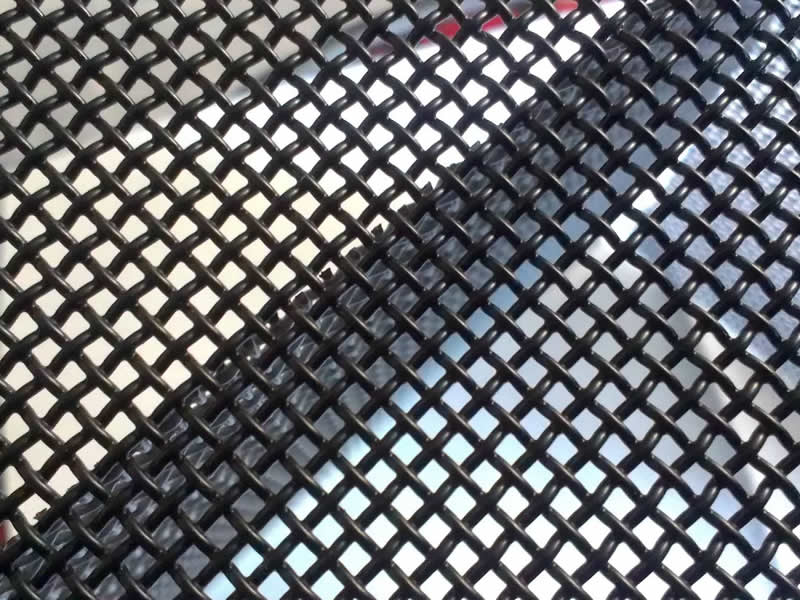

The efficacy of a security window screen is primarily defined by its technical specifications, which dictate its strength, durability, and functional attributes. Key parameters include the mesh count, wire diameter, tensile strength of the wire material, and the specific alloy composition. For instance, a common material specification is marine-grade 316L stainless steel, renowned for its superior corrosion resistance, particularly in coastal or high-humidity environments, offering a significant advantage over standard 304 stainless steel. Wire diameters typically range from 0.8mm to 1.0mm, with the mesh count (wires per inch) inversely related to the wire diameter to maintain sufficient open area for visibility and airflow. A higher wire diameter and specific weaving pattern contribute directly to enhanced shear resistance and impact absorption, crucial for deterring forced entry. Tensile strength, measured in megapascals (MPa), indicates the material’s resistance to breaking under tension, with premium security screens often featuring wire tensile strengths exceeding 800 MPa, far surpassing that of conventional insect screens. The coating applied, such as electrostatically applied powder coating, not only provides aesthetic finish but also adds a protective layer against abrasion and environmental degradation, prolonging the product's operational lifespan. Understanding these intricate technical details is crucial for B2B purchasers, as they directly influence the screen’s ability to meet stringent security requirements, ensuring the chosen security window screen mesh solution provides the necessary level of protection and longevity for the intended application, whether in high-security zones or general commercial properties. These detailed specifications are rigorously tested against international standards such as ASTM F1233 for forced entry resistance, ensuring performance reliability.

| Parameter | Typical Range/Value | Significance for Security |

|---|---|---|

| Material Grade | 304 / 316 / 316L Stainless Steel | Corrosion resistance, strength. 316L offers superior resistance. |

| Wire Diameter | 0.8mm - 1.0mm (0.031" - 0.039") | Directly impacts cut resistance and rigidity. Thicker wire = more robust. |

| Mesh Count | 10x10 to 12x12 wires/inch (2.0-2.5mm hole) | Balance of security, visibility, and airflow. Prevents small object penetration. |

| Tensile Strength | 700 MPa to 900 MPa (100,000 - 130,000 PSI) | Resistance to stretching and breaking under tension. Higher is better. |

| Coating Type | Electrophoretic Coating, Powder Coating (AkzoNobel, DuPont) | Corrosion protection, UV resistance, aesthetic finish, increased lifespan. |

| Corrosion Resistance | Salt Spray Test (ASTM B117) > 1000 hrs | Indicates durability in harsh environments. Critical for longevity. |

| Impact Resistance | Knife Shear Test, Dynamic Impact Test (AS 5039/5041) | Ability to withstand physical attacks and blunt force trauma without breaching. |

The production of a durable security window screen involves a sophisticated multi-stage manufacturing process that ensures its structural integrity and long-term performance. It begins with the selection of premium-grade raw materials, primarily high-tensile stainless steel wire, typically 304, 316, or 316L alloys, chosen for their inherent strength and corrosion resistance. The wire undergoes a precise drawing process to achieve the exact specified diameter, maintaining uniformity across the entire length. This is followed by the weaving phase, where advanced automatic weaving machines interlace the warp and weft wires under immense tension to create a highly robust and uniform mesh structure, often in a plain weave or twill weave pattern to maximize stability and prevent unraveling. After weaving, the mesh undergoes a series of crucial post-processing treatments. This includes rigorous cleaning and degreasing to prepare the surface for coating, followed by an electrophoretic deposition (EPD) process, which applies a base layer of anti-corrosion primer. This electrically charged primer ensures uniform coating coverage even within the intricate mesh structure, providing a foundational shield against rust and environmental wear. Subsequent to EPD, a final layer of high-quality powder coating, often from reputable suppliers like AkzoNobel or DuPont, is electrostatically applied and then cured at high temperatures. This not only imparts the desired color and aesthetic finish but also enhances UV resistance, abrasion resistance, and overall durability. Throughout each stage, stringent quality control measures are implemented, adhering to international standards such as ISO 9001 for quality management and ANSI/ASCE for structural integrity. Inspections include visual checks for defects, dimensional accuracy measurements, and mechanical tests such as tensile strength tests, impact resistance tests (e.g., knife shear test, dynamic impact test per AS 5039/5041), and accelerated corrosion tests (e.g., salt spray test per ASTM B117 for over 1000 hours). This meticulous manufacturing and testing regimen ensures that every security window screen mesh product meets the highest standards for performance, longevity, and reliability, delivering superior protection for various applications in demanding industries such as petrochemical, metallurgy, and critical infrastructure, where resistance to harsh elements and forced entry is paramount, contributing to energy efficiency by reducing solar gain and enhancing airflow.

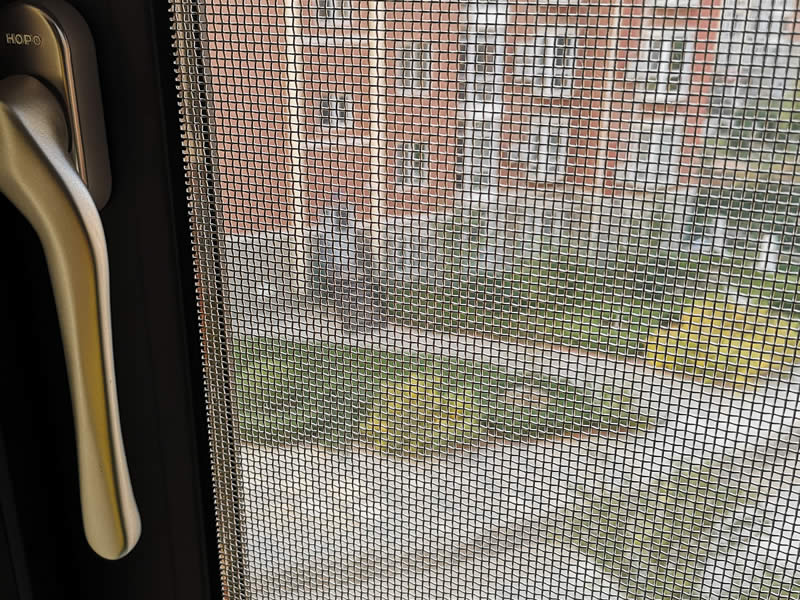

The deployment of high-grade security window screen solutions offers a multi-faceted array of technical advantages that extend far beyond simple intrusion prevention, delivering comprehensive value for B2B applications. Foremost among these is their exceptional physical strength and resistance to forced entry, stemming from the use of high-tensile stainless steel wire, typically with a breaking strength that can withstand significant impacts from blunt objects or cutting tools, including bolt cutters or knives, as evidenced by compliance with standards like AS 5039. This inherent robustness provides a formidable barrier against unauthorized access, safeguarding assets and personnel. Beyond overt security, these screens offer superior corrosion resistance, particularly when fabricated from marine-grade 316L stainless steel and treated with advanced electrophoretic and powder coatings. This makes them ideal for installation in harsh environments, including coastal regions, industrial zones with high pollutant levels, or facilities exposed to chemical agents, ensuring a prolonged service life of often 10-15 years without significant degradation. Furthermore, their design contributes significantly to energy efficiency; the precise weave and dark coating can reduce solar heat gain by up to 60%, thereby lowering cooling costs in warmer climates, while simultaneously maintaining excellent airflow for natural ventilation. The fine mesh also acts as an effective insect barrier, eliminating the need for separate screens. Despite their strength, advanced manufacturing techniques ensure remarkable optical clarity and minimal visual obstruction, preserving aesthetic appeal and outward visibility. This combination of physical security, environmental durability, energy savings, and uncompromised visibility makes a premium security window screen a strategically advantageous investment, enhancing the safety, sustainability, and comfort of any commercial or industrial facility. These advantages underscore why such screens are considered a crucial element of modern integrated security systems, offering passive yet powerful protection.

The versatility and robust performance of security window screen solutions render them indispensable across a wide spectrum of B2B applications, addressing diverse security and environmental challenges. In the commercial sector, these screens are extensively deployed in retail establishments, banks, and corporate offices to deter smash-and-grab thefts and provide a layer of protection during non-business hours without compromising natural light or exterior aesthetics. For critical infrastructure, such as power stations, water treatment facilities, and communication hubs, the screens serve as a crucial physical barrier against vandalism, sabotage, and unauthorized access, integrating seamlessly with existing perimeter security systems. In the industrial domain, including petrochemical plants, mining operations, and manufacturing facilities, the corrosion-resistant properties of the security window screen mesh are particularly valuable, protecting vulnerable points from environmental degradation while preventing unauthorized entry and enhancing safety. Furthermore, in educational institutions and healthcare facilities, these screens offer a dual benefit: ensuring the safety of students, staff, and patients by preventing falls or unauthorized egress, while also providing a secure barrier against external threats. Residential sectors demanding high security, such as luxury estates, multi-unit dwellings, and remote properties, also greatly benefit from these screens, integrating with security doors and windows to form a comprehensive defensive perimeter that deters intruders effectively. For instance, a recent project involved equipping a large data center in a high-risk urban area with custom-fitted 316L stainless steel security screens, significantly enhancing their physical security posture against advanced intrusion techniques. The screens’ ability to maintain airflow was crucial for cooling efficiency, further highlighting their multi-functional advantage. Another case involved a coastal resort where the screens provided robust protection against both forced entry and saltwater corrosion, maintaining aesthetic appeal and structural integrity over years of exposure. These varied applications underscore the adaptability and effectiveness of these solutions in meeting stringent security demands across diverse operating environments.

Selecting the right manufacturer for security window screen solutions is a pivotal decision for B2B clients, directly impacting the longevity, effectiveness, and compliance of the deployed security infrastructure. A comprehensive evaluation process should extend beyond initial cost to encompass several critical factors. Firstly, scrutinize the manufacturer’s adherence to international quality and testing standards; certifications like ISO 9001, along with compliance to specific security performance standards such as ASTM F1233 (forced entry resistance) or Australian Standards AS 5039/5041 (security screen tests), serve as authoritative indicators of product reliability and consistency. Reputable manufacturers will readily provide third-party test reports and certification documentation. Secondly, assess the transparency and traceability of their material sourcing and manufacturing processes. Understanding the origin and grade of stainless steel (e.g., whether it is truly 316L marine grade), and the type and quality of coatings used (e.g., powder coatings from leading suppliers like AkzoNobel or DuPont), is crucial for predicting long-term performance and corrosion resistance. Manufacturers with a proven track record, extensive service years in the industry, and a robust portfolio of successful projects—particularly within your specific sector—demonstrate substantial experience and authority. Thirdly, evaluate their capacity for customization and their technical support infrastructure. The ability to provide tailored solutions for unique architectural requirements, unusual window dimensions, or specialized environmental conditions, combined with comprehensive pre-sale consultation and post-installation support, signifies a vendor committed to long-term client success. Lastly, consider their warranty commitments and delivery lead times. A strong warranty reflects confidence in product durability, while efficient and reliable logistics ensure project timelines are met. By thoroughly vetting manufacturers against these criteria, B2B clients can ensure they partner with a supplier who delivers superior security window screen mesh products that not only meet but exceed their rigorous security and operational demands, providing a genuine return on investment through enhanced safety and reduced maintenance.

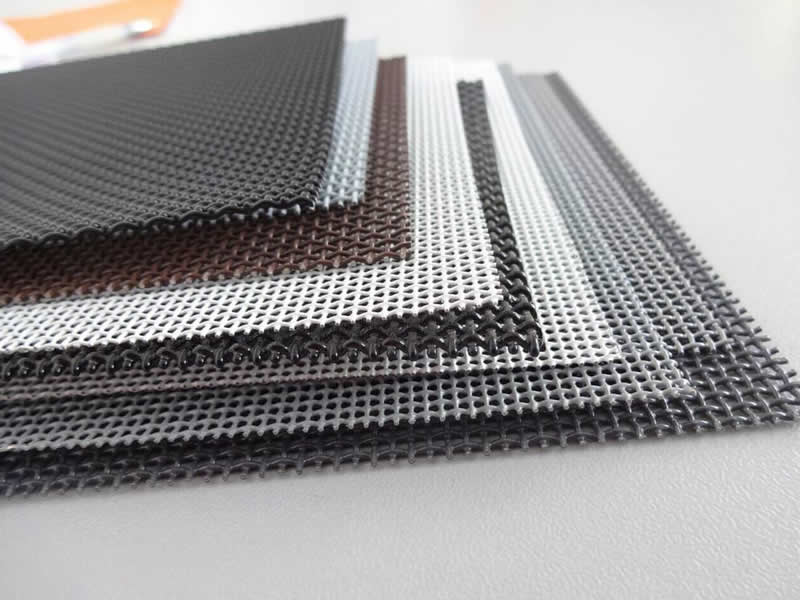

Recognizing that no two B2B projects are identical, leading manufacturers of security window screen solutions offer extensive customization capabilities to meet highly specific architectural, environmental, and security requirements. This bespoke approach ensures optimal integration and maximum performance for every unique application. Customization options typically span several key areas. Dimensional precision is paramount, allowing screens to be fabricated to exact window and door frame measurements, accommodating non-standard shapes such as arches, circles, or irregular polygons, and ensuring a seamless, gap-free fit that enhances both security and aesthetics. Material specifications can also be customized; while 304 and 316L stainless steel are standard, specific projects may require different alloys for enhanced resistance to particular chemical agents or extreme temperatures, ensuring the security window screen mesh performs optimally in niche industrial environments like those in the petrochemical or pharmaceutical sectors. Furthermore, clients can often specify specialized coatings, beyond standard black or white powder coats, to match specific branding guidelines or integrate perfectly with building facades. Options include various RAL colors, textured finishes, or even anti-graffiti coatings, which not only enhance durability but also contribute to the long-term visual integrity of the property. Integration with existing access control or alarm systems is another crucial aspect of customization, allowing for features like emergency exit mechanisms or tamper-detection sensors to be seamlessly incorporated into the screen’s framing system. This level of adaptability ensures that the security solution is not a generic add-on but an architecturally sympathetic and functionally integrated component of a broader security strategy. The ability to provide such precise and multi-faceted customization solidifies a manufacturer's position as a reliable partner for complex, high-stakes projects requiring more than off-the-shelf security doors and windows, demonstrating true expertise and problem-solving capabilities.

A security window screen is fundamentally distinct from a standard insect screen in terms of material, construction, and primary function. While both prevent insects, a standard screen is typically made from lightweight fiberglass or aluminum mesh with a low tensile strength, easily cut or pushed through. In contrast, a security screen is engineered from high-tensile stainless steel wire (e.g., 304 or 316L grade), often with a wire diameter of 0.8mm to 1.0mm, and woven into a dense, robust mesh. This construction provides exceptional resistance to cutting, impacts, and forced entry attempts, acting as a significant physical barrier against intruders. Security screens are also often treated with advanced corrosion-resistant coatings, ensuring a service life of 10-15 years or more, far exceeding that of conventional screens, and comply with rigorous standards like AS 5039/5041 for forced entry.

Yes, high-quality security window screen products are specifically designed to endure a wide range of extreme weather conditions. Their robust construction using marine-grade stainless steel (316L) provides superior resistance to corrosion, making them ideal for coastal areas exposed to saltwater spray or industrial environments with high humidity and chemical pollutants. Furthermore, the specialized powder coatings applied during manufacturing are UV-stabilized, preventing fading and degradation from prolonged sun exposure. These screens are also engineered to withstand significant wind loads and resist damage from hailstones or other impacts, maintaining their structural integrity and protective capabilities even in severe storms. This durability ensures a long service life and consistent performance across diverse climatic zones, minimizing maintenance and replacement costs for businesses.

The typical lead time for a custom security window screen order can vary depending on the complexity of the project, the volume of units required, and the current production schedule of the manufacturer. For standard custom sizes and designs, lead times usually range from 3 to 6 weeks from the confirmation of specifications and receipt of payment. However, highly specialized requests involving unique materials, intricate designs, or very large quantities may require extended lead times, potentially up to 8-10 weeks. Reputable manufacturers prioritize clear communication regarding delivery schedules, providing clients with realistic timelines upfront. It is always advisable to discuss specific project deadlines during the initial consultation to ensure alignment and to allow for any necessary adjustments in the production plan, guaranteeing timely delivery for critical installations.

Establishing trust and ensuring long-term client satisfaction are paramount in the B2B sector, particularly for critical security infrastructure like security window screen systems. A reliable manufacturer will provide clear, transparent information regarding their delivery cycles and comprehensive warranty commitments. For standard orders, a typical delivery cycle can range from 2 to 4 weeks, depending on the volume and customization required, while complex or large-scale projects might necessitate 6 to 8 weeks for manufacturing and logistics. Manufacturers with robust supply chain management and efficient production lines are better positioned to meet demanding project timelines, minimizing delays and ensuring that installations proceed as scheduled. This operational efficiency is a key indicator of a manufacturer's professionalism and capability. Equally important is the warranty commitment, which serves as a testament to product quality and manufacturer confidence. Most reputable suppliers offer a minimum 10-year warranty on the security window screen mesh itself, covering defects in materials and workmanship, and often a shorter warranty (e.g., 5-7 years) on the coating against bubbling, peeling, or fading, provided proper maintenance is followed. This extensive warranty period underscores the product's expected service life and provides B2B clients with significant peace of mind regarding their investment. Furthermore, dedicated customer support teams are crucial, offering technical assistance, troubleshooting, and post-sales service to ensure the ongoing optimal performance of the installed security doors and windows, thereby enhancing overall client trust and satisfaction. This holistic approach to service and commitment reinforces the value proposition of a high-quality security solution.

This is the last article

JOIN OUR NEWSLETTER

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.