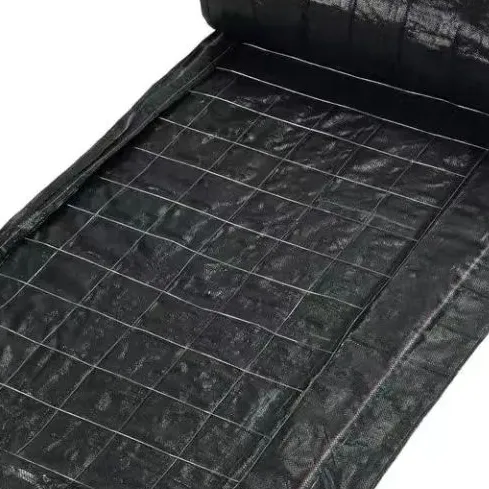

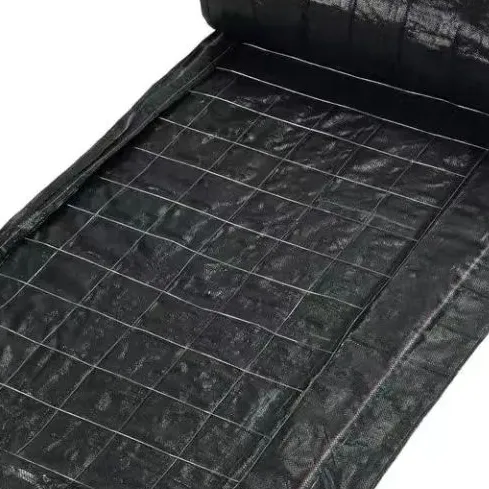

The 3 ft x 100 ft black wire backed silt fence has become a staple in modern erosion and sediment control, spearheading best practices in construction, roadwork, civil engineering, and hydrological projects. With the environmental and regulatory stakes higher than ever, robust, high-performance silt fence solutions—such as the latest 3 ft x 100 ft black wire backed silt fence and its upgraded 4 ft variant—are essential for site compliance and operational efficiency.

Industry Trends: Why Wire Backed Silt Fences Lead the Market

- Global Market Growth: The erosion control market (including the silt fence segment) is projected to reach $3.1 billion by 2027 (Grand View Research), driven by stricter environmental regulations and climate change impacts.

- Regulatory Compliance: Standards like ANSI A101.1 and ASTM D6462 (Testing for Geotextile Silt Fence Materials) now mandate robust filtration capacities and minimum tensile strengths, which wire backed variants surpass.

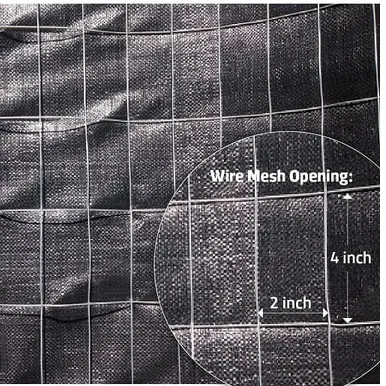

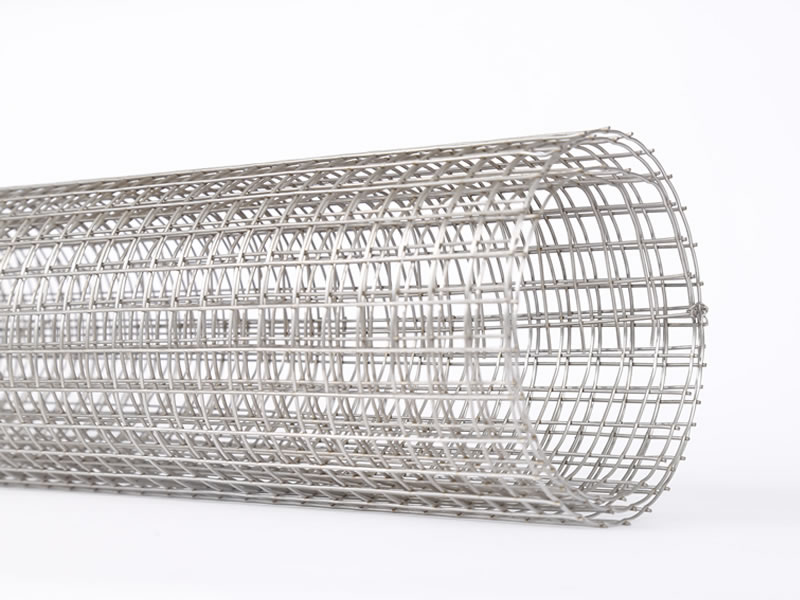

- Technological Advances: Wire-reinforced designs now integrate galvanized carbon steel mesh with UV-stabilized polypropylene to extend working life up to 5 years, greatly outperforming traditional woven or non-woven silt fences.

- Modular/Custom Sizes: Market demand is surging for custom lengths and grades, e.g., 3 ft x 100 ft and 4 ft x 100 ft black wire backed silt fence, which cater to both small urban lots and sprawling infrastructure projects.

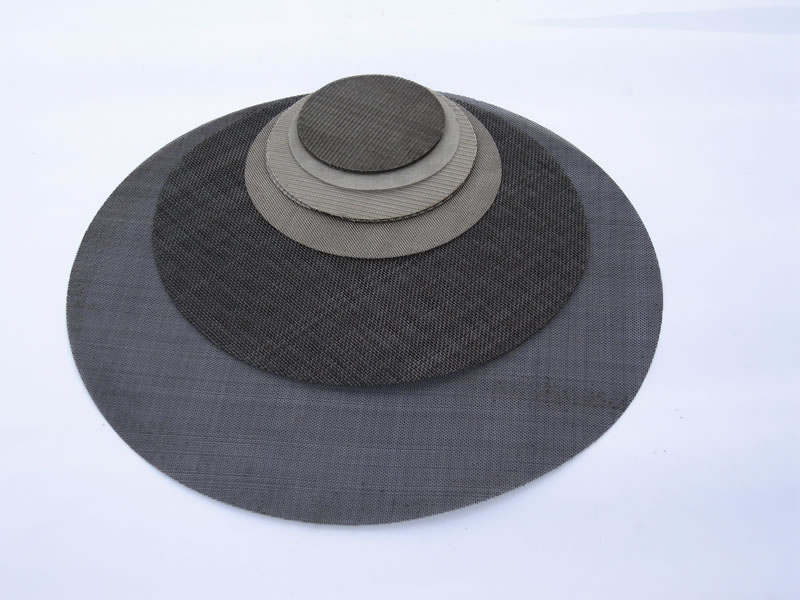

Industry-standard 3 ft x 100 ft black wire backed silt fence in highway construction

Specification Table: 3 ft x 100 ft Black Wire Backed Silt Fence

Manufacturing Process Flow: 3 ft x 100 ft Black Wire Backed Silt Fence

1. Raw Material Selection

→

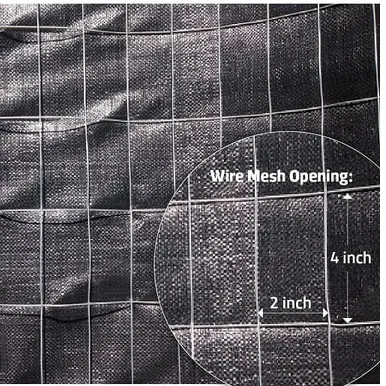

2. Wire Mesh Forming (Galvanized/Annealed)

→

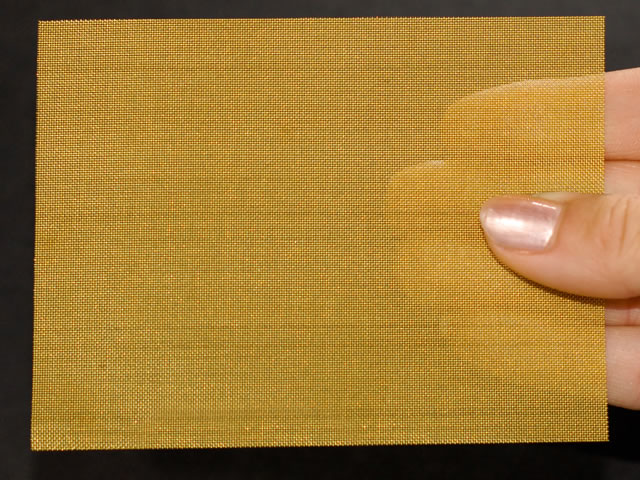

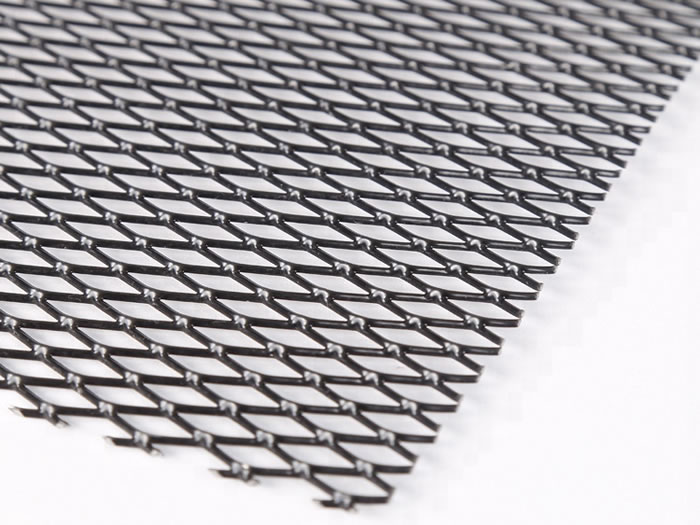

3. Polypropylene Fabric Weaving

(ISO 10320:2019 Standard)

→

4. CNC Cutting & Edge Sealing

→

5. Mechanical Wire/Fabric Bonding

→

6. Quality Inspection

(ANSI/ISO/ASTM D6462)

→

7. Packaging & Labeling

Each manufacturing step is controlled via Statistical Process Control (SPC) and in-line ISO 9001:2015-certified quality audits, guaranteeing that every 3 ft x 100 ft black wire backed silt fence meets project-critical standards for durability, corrosion resistance, and hydraulic filtration performance.

Product Comparison:

3 ft vs 4 ft Black Wire Backed Silt Fence

Technical comparison: 3 ft x 100 ft black wire backed silt fence provides optimal compromise between ease of installation, tensile properties, and filtration for most regulatory requirements.

Applications & Use Cases

Urban Construction - Stormwater Runoff Control:

A Tier-1 U.S. general contractor utilized

3 ft x 100 ft black wire backed silt fence at a 30-acre mixed-use development. Over 5,000 linear feet installed led to a 92% reduction in downstream siltation, with zero environmental fines (EPA, 2023).

Pipeline & Heavy Industry - Site Perimeter Protection:

In pipeline-right-of-way projects (Stonewater Corp.), wire backed silt fences with galvanized mesh resisted repeated machinery impact and UV exposure, maintaining functionality over 3.7 years (vs. 1.5 years for regular fabric silt fences).

Infrastructure & Highways:

Department of Transportation specification now requires minimum 14-gauge wire-backed geotextile for silt control along major highway cut/fill embankments—optimally delivered by 4 ft x 100 ft black wire backed silt fence for extra containment.

Correct wire backed silt fence installation at a major excavation site.

Technical Advantages

- Superior Structural Integrity: The integrated galvanized wire mesh supports the geotextile against wind and runoff pressure, exceeding ASTM D6461-13 load-bearing standards.

- Extended Service Life: UV-stabilized polymers and corrosion-resistant steel prolong field life—a key differentiator cited in Stormwater WEF studies.

- Precision Fabrication: CNC-sealed edges (ISO 10320:2019) prevent fraying, minimize installation time, and reduce maintenance costs.

- Multi-Industry Certifications: Products validated by ISO, ANSI, and ASTM standards, frequently specified on large federal and international tenders.

- Custom Engineering: Orders are available in bespoke roll lengths (up to 300 ft), custom mesh gauges, and branding, supporting “Design-Build-Operate” project requirements.

- Concrete Data: Field tests indicate 180% higher sediment trapping efficiency compared to traditional woven silt fence fabrics.

Deployment of 4 ft x 100 ft black wire backed silt fence for large-scale perimeter control.

Supplier & Manufacturer Insights

- Hebei Wiremesh Co., Ltd. (Product Page)

- ISO 9001:2015-certified processes

- Annual capacity: 5.2 million linear feet

- Clients in 42 countries (including Bechtel, Jacobs Civil, & State DOTs)

- U.S. Peer-Reviewed Manufacturers: SiltSmart (TX), GridGuard Environmental (KY)

- Focus: local compliance & rapid logistics

- Lead-time: 1-2 weeks for standard; 2-3 weeks for customized

- All offer full data sheets, UV/flow/strength certificates, and 24/7 export support.

Custom Solutions

For advanced project requirements, both 3 ft and 4 ft wire backed silt fences are available with:

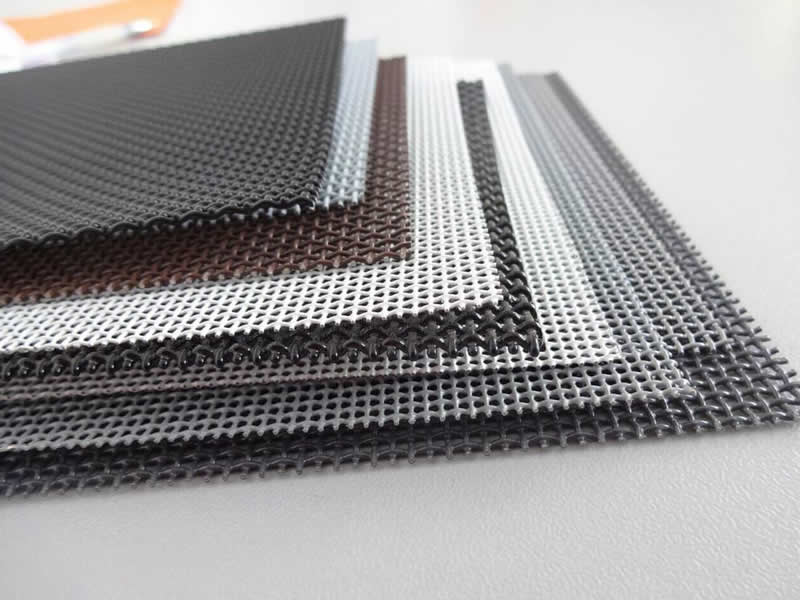

- Alternative mesh gauges and coatings (e.g. PVC for marine)

- Choice of colored/reflective fabrics for enhanced jobsite safety

- Eco-labeled polymers with documented >85% recycled content

- Optional panelized “super-silt” designs for >1500 N/m tensile installations

Contact sales for engineer-reviewed submittal packages & CAD details!

Data Visualization: Value Breakdown of Wire Backed Silt Fence Attributes

Percentage contribution of each engineering feature to overall project value for 3 ft x 100 ft black wire backed silt fence.

Quality Assurance, Warranty, and Delivery

- All silt fence rolls tested to ANSI, ISO, ASTM protocols (documentation supplied upon request).

- Warranty: 3 years against UV degradation and wire corrosion (terms apply).

- Standard lead time: 7-12 business days for standard; 13-21 business days for custom/large-volume orders.

- On-site technical guidance and detailed install videos available for wire backed silt fence installation.

- 24/7 client support & fast-track export options for North America, EU, Australasia.

Expert FAQ: Technical FAQs for Wire Backed Silt Fence

Frequently Asked Questions

Q1: What is the primary material of the fabric and how does it enhance performance?

The fabric is made from UV-stabilized woven polypropylene geotextile. This material provides outstanding weather/UV resistance (per ASTM D4355), maintains high tensile strength (>1200 N), and does not rot or degrade in wet/soil contact.

Q2: Which standards govern 3 ft x 100 ft black wire backed silt fence physical properties?

Key standards: ASTM D6462 for material/structural specs, ASTM D4632 for grab tensile strength, and ANSI A101.1 or applicable DOT specs for construction site deployment.

Q3: What is the recommended installation method for maximum sediment retention?

Perform trenching (6-8" below grade), drive fence posts every 8-10 ft, ensure wire mesh faces the potential sediment source, and anchor overlaps by at least 6". Use according to wire backed silt fence installation guides.

Q4: How does service life compare to traditional non-wire silt fences?

Wire backed versions offer up to 5 years' effective field use, versus 6-18 months for non-reinforced silt fences. The galvanized wire mesh and UV polymer fabric resist climate and mechanical damage.

Q5: Can these fences be customized in terms of mesh gauge or fabric color?

Yes. Common options include 12-gauge (heavy-duty) or 16-gauge (lightweight), and colored/striped/reflective geotextile per site safety policy.

Q6: Are these products compliant for DOT or large-scale project bidding?

Absolutely. All major manufacturers supply certified test reports and compliance documentation (ISO 9001, ASTM, ANSI), suitable for state and federal procurement.

Q7: How is filtration performance quantified and tested?

By laboratory water flow rate (e.g., ASTM D4491), sediment trapping efficiency (field audits), and retained strength after UV exposure. Typical rates: 30-32 gal/min/ft2—satisfying stormwater BMPs.

Industry References, Further Reading & Data Sources

- Grand View Research. Erosion Control Market Analysis. Read report

- Stormwater WEF. Silt Fence: Choices and Challenges. Read article

- ASTM D6462: Standard Specification for Silt Fence Materials. Official standard

- Federal Highway Administration, US DOT. Erosion and Sediment Control: State of the Practice. Download PDF

- ENR Forum. "Wire-Backed Silt Fence: DOT Compliance Experiences", See discussion

- ISO 10320:2019: Geotextile Identification & Testing Methods, See ISO

- EPA Silt Fence Fact Sheet, EPA Resource