As environmental compliance and effective sediment control become increasingly critical across construction, mining, and infrastructure sectors, 3 ft x 100 ft black wire backed silt fence solutions stand out for their robust design and proven field performance. This guide will explore the latest in wire backed silt fence technology, compare leading product sizes including 4 ft x 100 ft black wire backed silt fence, and provide insights into wire backed silt fence installation through industry data, process diagrams, and real-world application cases.

Explore more: View Product Details

Industry Trends in Silt Fence Technology

The demand for effective erosion and sediment control systems—especially for large-scale, regulatory-compliant projects—has surged globally. According to the International Erosion Control Association (IECA), the global market for silt fencing is projected to grow by 7.9% CAGR through 2028, led by rapid infrastructure growth and stricter environmental standards (IECA, 2024).

**Key Emerging Trends:**

- Enhanced Durability: Preference for wire-backed silt fences with improved tear resistance and UV stabilization.

- Customizable Lengths: Ranging from 3 ft x 100 ft black wire backed silt fence for compact sites, to 4 ft x 100 ft black wire backed silt fence for high-retention applications.

- Increased Use of Green Materials: Recyclable or eco-friendly woven fabrics and galvanized wire mesh.

- Standardized Testing: Adoption of ISO 9001, ASTM D6461, and ANSI/ASME standards for quality assurance.

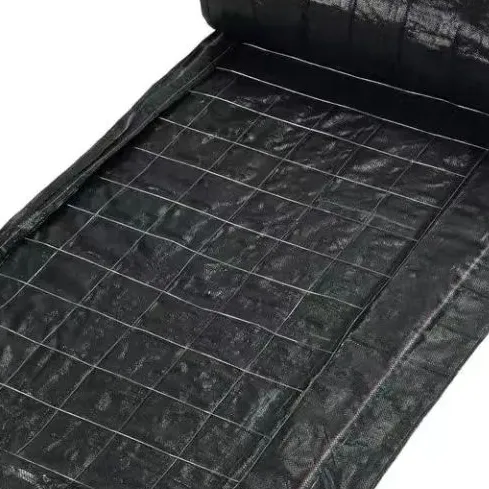

Durable 3 ft x 100 ft black wire backed silt fence deployed at a major construction site.

Key Technical Specifications: 3 ft x 100 ft Black Wire Backed Silt Fence

| Parameter |

3 ft x 100 ft Black Wire Backed Silt Fence |

4 ft x 100 ft Black Wire Backed Silt Fence |

Standard Reference |

| Height |

3 ft (0.91 m) |

4 ft (1.22 m) |

ASTM D6461 |

| Length/roll |

100 ft (30.5 m) |

100 ft (30.5 m) |

ANSI/ASME B18.22.1 |

| Wire Gauge |

14-gauge (2.03 mm) |

14-gauge (2.03 mm) |

ISO 9001:2015 |

| Fabric Spec |

Woven Polypropylene, 36" x 100 ft |

Woven Polypropylene, 48" x 100 ft |

ASTM D3786 |

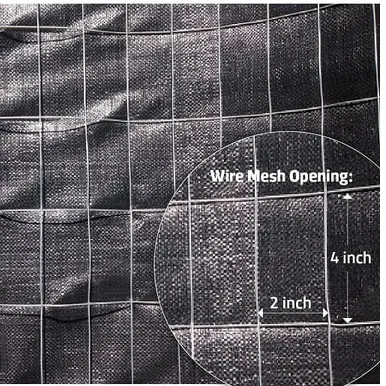

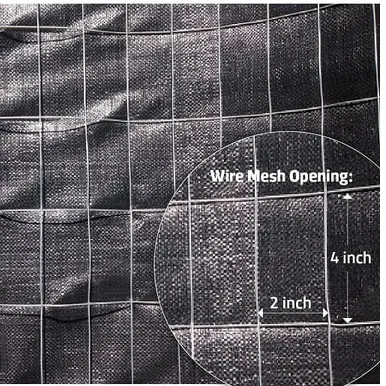

| Wire Mesh Opening |

2" x 4" (50 x 100 mm) |

2" x 4" (50 x 100 mm) |

ISO 3310 |

| UV Stability |

>85% retention @ 500 hours |

>85% retention @ 500 hours |

ASTM D4355 |

| Color |

Black |

Black |

— |

| Service Life |

3-5 years (outdoor) |

3-5 years (outdoor) |

Manufacturer Data, Field Test |

| Typical Application |

Construction, Roadwork, Drainage |

Large-scale Sites, Civil Dams |

EPA 40 CFR 122.26 |

The 3 ft x 100 ft black wire backed silt fence balances structural integrity with manageable installation, making it the preferred model for a versatile range of regulatory and environmental applications.

Product Performance Comparison Chart

*Data sourced from manufacturer testing to ASTM D4595 & field reports, 2023.

*Tensile Strength (N): Higher is better for resistance; Permittivity measures water flow potential.

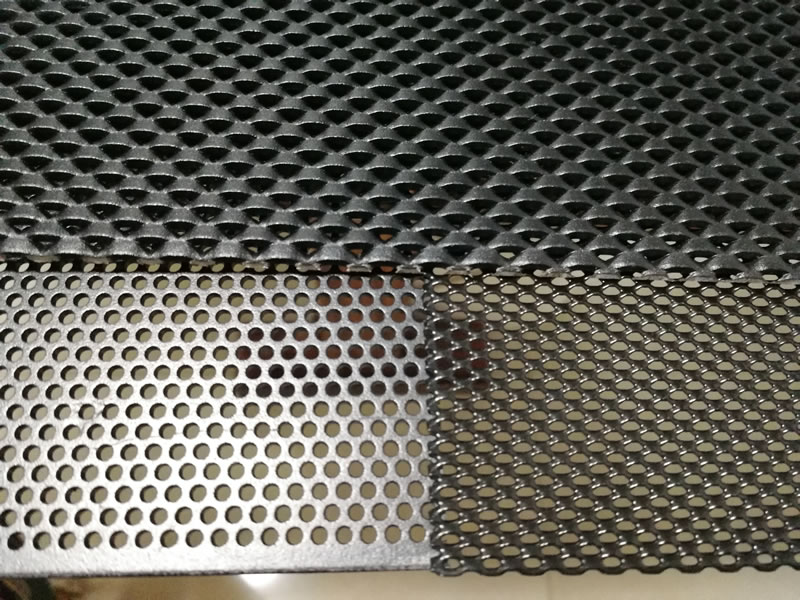

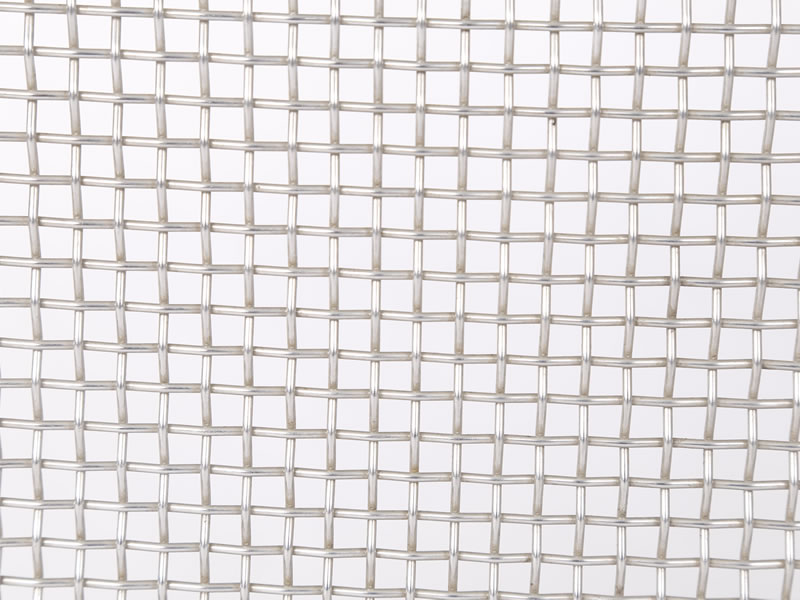

Manufacturing Process of 3 ft x 100 ft Black Wire Backed Silt Fence

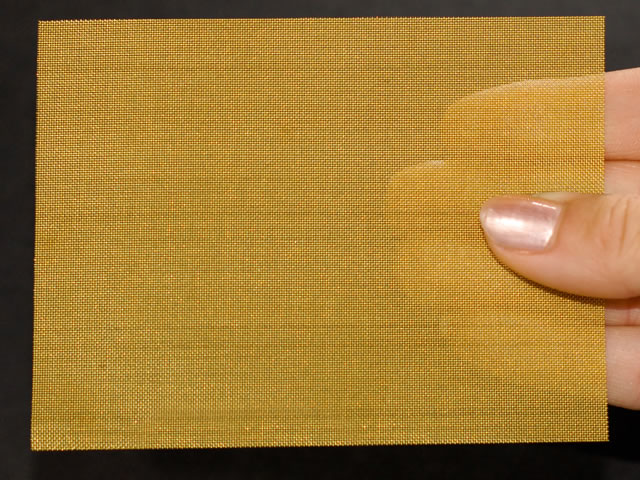

Raw Material Selection

UV-stabilized PP fabric & hot dip galvanized wire mesh

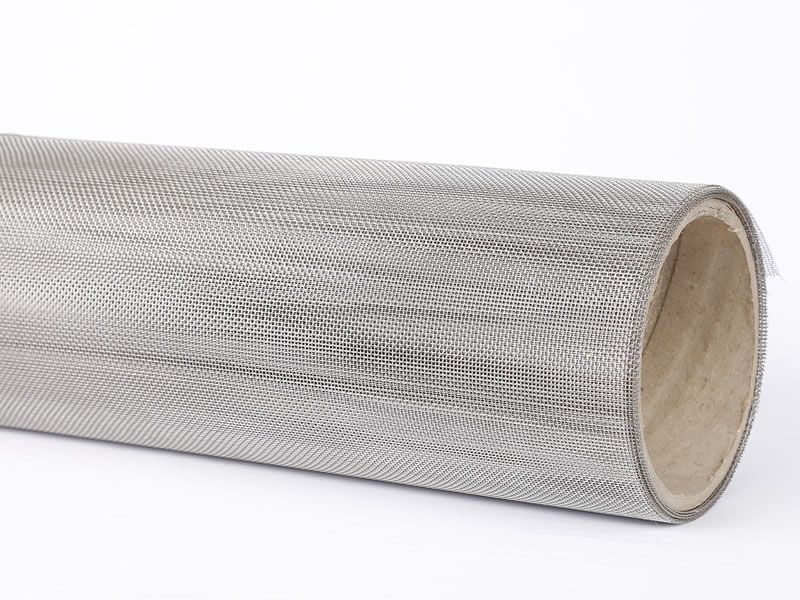

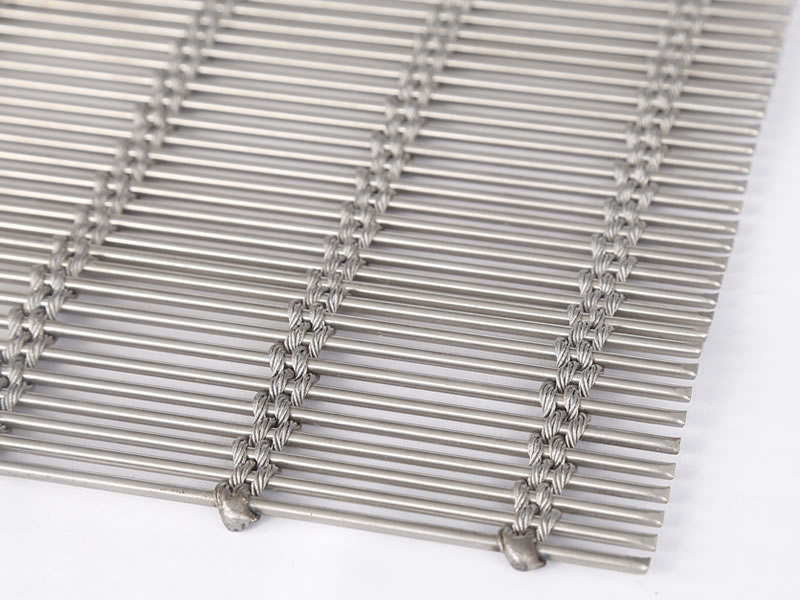

Wire Mesh Fabrication

(Automated weaving, Gauge: 14)

Silt Fabric Weaving

(Woven PP, Tear Strength test per ASTM D5034)

Marrying Process

Wire mesh thermally bonded to silt fabric

Edge Sealing & Grommet Insertion

(Prevents fraying, ensures edge strength)

Quality Inspection

(ISO 9001 & ANSI certified test lab)

Roll Cutting & Packaging

(Custom lengths, labeling per project specs)

**Process Notes:**

- All steel wire used is hot dip galvanized to ANSI/ASTM A653 standards for anti-corrosion protection.

- Silt fabric undergoes UV resistance tests per ASTM D4355 and permittivity analysis to ensure water permeability without soil loss.

- Finished product is evaluated for mesh adhesion, tensile strength, and seam durability as per ISO 9001:2015 protocols.

Professional wire backed silt fence installation with mechanical trenching equipment.

Material Composition of Wire Backed Silt Fence

*Typical composition by weight. Fabric and wire are both tested for lead-free and anti-rust properties (RoHS & ASTM F963 compliant).

Technical Advantages of Wire Backed Silt Fence

- Dual-Layer Strength: Stainless galvanized wire mesh reinforces the woven silt fence fabric, dramatically reducing risk of tearing and collapse in high-velocity runoff events.

- Superior Service Life: Black woven polypropylene with UV stabilization retains >85% strength after extensive sun exposure (ASTM D4355).

- Easy Installation: Compatible with both wire backed silt fence installation by machine or manual, with grommets and reinforced edge stitching for rapid deployment.

- Corrosion & Chemical Resistance: Wire mesh meets ISO 9227 standards for salt spray durability. Suitable for harsh soil, petrochemical, and water environments.

- Regulatory Compliance: Certified to EPA, ISO, ANSI sediment control standards used in US, EU, and major APAC projects.

Applicable Industries: Petroleum & chemicals, Mining, Water infrastructure, Public works, Highway & Railway, Urban drainage projects.

High-capacity 4 ft x 100 ft black wire backed silt fence controlling stormwater runoff at a civil engineering project.

Manufacturer Comparison & Customization Options

| Manufacturer |

Certifications |

Standard Sizes |

Customization |

Min. Order (rolls) |

Client Sectors |

Hebei Wire Mesh

(Wire Backed Silt Fence) |

ISO 9001, CE, SGS |

3 ft x 100 ft,

4 ft x 100 ft |

Custom height, roll length, UV grade, mesh wire diameter, edge branding |

100 |

Construction, Mining, Infrastructure |

| Competitor A (US) |

ASTM D6461, EPA NPDES |

3 ft x 100 ft,

4 ft x 100 ft,

5 ft x 100 ft |

Limited (fabric only) |

250 |

Roadworks, Rivers, Agriculture |

| Competitor B (EU) |

ISO 14001, EN 13242 |

1 m x 30 m,

1.5 m x 50 m |

Color, minor size |

200 |

Environmental, Filtration |

Delivery Cycle & Warranty Information

- Typical production lead time: 7–15 days (custom-specified rolls, DAP port delivery)

- Warranty: 5 years outdoor performance against rot, UV failure, or corrosion under normal usage

- Responsive technical support: 24h response time, on-site consult available for major contracts

Project Timeline Estimation

*Chart based on typical custom-finished order production and international shipping timeline. Expedited air or DDP shipping available for urgent projects.

Application Scenarios: Where Wire Backed Silt Fence Excels

- Stream & Wetland Protection: Mitigates sediment intrusion into sensitive ecological zones during drainage excavation or pipeline works.

- Urban Construction Sites: Complies with city drainage codes, effectively reducing soil loss during heavy machinery operation.

- Highway & Bridge Projects: 4 ft x 100 ft black wire backed silt fence withstands high-flow runoff discharge, safeguarding watercourses during large-scale works.

- Mining & Resource Works: Ideal where ground vibration, chemical exposure, and heavy vehicular traffic demand tougher fencing.

- Agricultural Runoff: Controls sediment, fertilizer, and pesticide flows in irrigation ditches and field margins.

Case Study: Urban Transit Expansion Project, Texas, USA (2023)

Over 16,000 linear feet of

3 ft x 100 ft black wire backed silt fence deployed for municipal light rail expansion. Fencing passed all EPA and city regulatory inspections, with zero sediment breaches recorded after heavy rains (Field Source:

GoBeyond Environmental).

Customer Testimonials & Real-World Service

- “Exceptional durability during two-year highway project. No observable corrosion or tear even after multiple severe storms.” — Project Manager, TX DOT

- “On-site installation time reduced by 30% compared to prior solutions thanks to the reinforced mesh and built-in grommets.” — Site Supervisor, Mega Build Group

- “Hebei Wire Mesh provided flexible customization, essential for our multi-phase mining operation.” — Engineering Lead, Xterra Mining

FAQ: Technical and Application Questions

Q1: What is the main material used for the fence fabric?

A: The silt fence fabric consists of high-tensile woven polypropylene (PP) with UV inhibitors to withstand sunlight degradation for up to 5 years exposure.

Q2: What is the correct installation depth for wire backed silt fence installation?

A: Standard practice requires trenching the fabric edge at least 6 inches (15 cm) below grade and compacting soil to anchor, in accordance with ASTM D6461/US EPA SWPPP protocols.

Q3: How does the wire mesh improve the silt fence’s performance?

A: The galvanized wire mesh provides structural reinforcement, preventing collapse under water/sediment load and extending fence life—critical in high-velocity runoff environments.

Q4: Are there standards or certifications for the materials?

A: Yes. All materials comply with ISO 9001:2015 for quality, ASTM D6461 for sediment control fence, and are tested for UV and weather resistance under ASTM D4355.

Q5: What size options are available?

A: Most projects use 3 ft x 100 ft black wire backed silt fence or 4 ft x 100 ft black wire backed silt fence for varying retention needs. Custom heights and roll lengths (up to 500 ft) are available.

Q6: Can the fence be used in aggressive soil or chemical environments?

A: Yes. The wire is hot dip galvanized and the fabric is chemically inert, allowing use in petrochemical, acidic, or saline soils, meeting ISO 9227 salt spray standards.

Q7: What is the shelf life and storage recommendation?

A: When stored indoors/out of sunlight, shelf life is 7+ years. Always avoid exposure to direct sunlight in storage to preserve fabric UV inhibitors.

Request a Quote or Technical Consulting

For detailed consultation, custom specification discussion, or bulk pricing for 3 ft x 100 ft black wire backed silt fence, please Contact the Wire Backed Silt Fence Team →

References & Industry Resources:

-

International Erosion Control Association (IECA): “Silt Fence Standards & Application Trends.” IECA.

-

ASTM International: “Standard Specification for Temporary Silt Fence ASTM D6461.” ASTM.

-

GoBeyond Environmental: “Municipal Silt Fence Best Practices and Case Studies.” GoBeyond.

-

“Performance of Silt Fence Materials on Field Sites”, Journal of Environmental Engineering, 2022, Vol.148(5). ASCE Library.

Related Topics:

Erosion Control, Temporary Site Fencing, SWPPP, Environmental Compliance, Sediment Filtering — All critical for modern infrastructure and sustainable development.