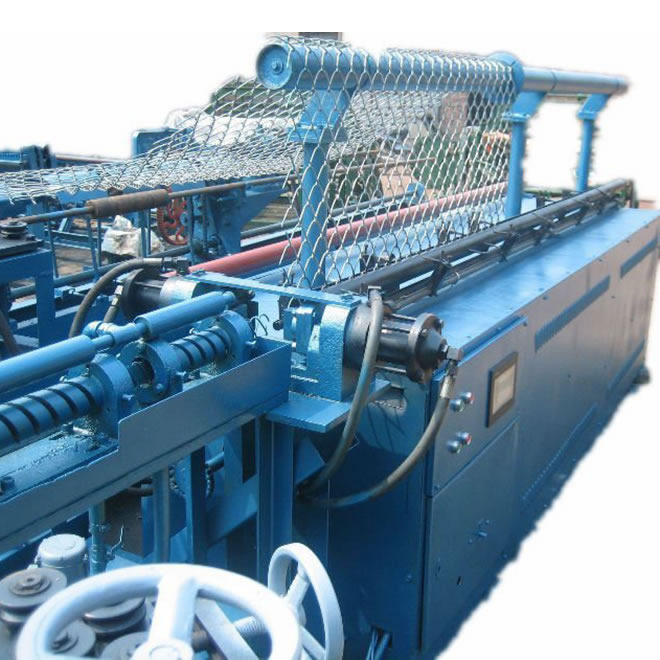

Looking for the right chain link fence machine for sale to boost your fencing business or manufacturing capabilities? You're in the right place! This in-depth guide unpacks market trends, critical product specs, advanced manufacturing, direct product comparison, custom project consultation, and real-world deployment—delivering unrivaled expertise for your purchase and long-term investment.

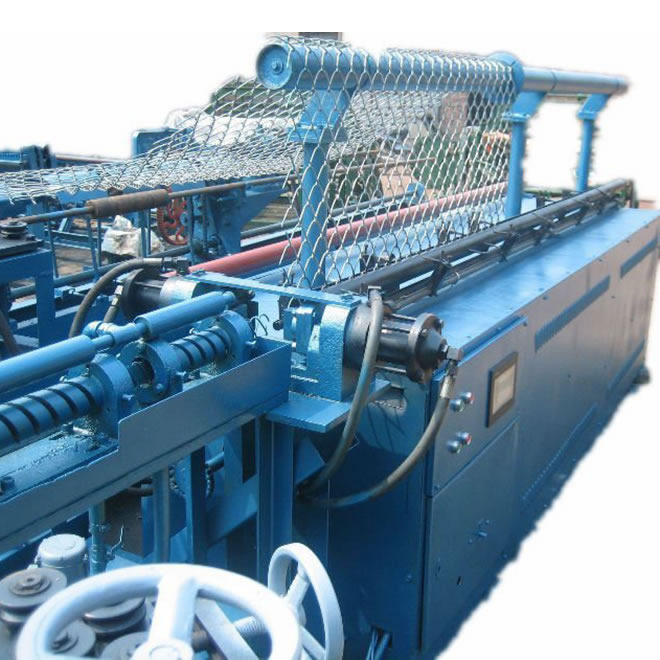

High-speed

chain link fence machine for sale: Modern automated line from

Hebei Wire Mesh

1. Market Trends & Overview – Global Chain Link Fence Machine Industry

Chain link fencing is one of the most widely used perimeter protection methods worldwide in industries like construction, sports, transportation, oil & gas, and urban infrastructure. As the demand for high-efficiency mesh fencing production grows, the need for robust chain link fence machine for sale solutions is surging.

Fact: According to Mordor Intelligence 2024, the global fencing market size is projected to exceed $38.6 billion by 2028, with chain link fencing maintaining over 25% market share. Key drivers include urbanization, security awareness, smart manufacturing adoption, and infrastructure expansion, especially in Asia, Europe, and North America.

- Automation and digital controls are the main technology trends.

- Steel wire, galvanized or PVC-coated, remains the material of choice due to its cost-effectiveness and corrosion resistance.

- High-speed + low-labor machines dominate new builds and retrofits.

- Compliance with ISO 9001, ISO 10223-6, and ASTM A392 standards enhances export capability.

Digital-controlled chain link machine for sale: Full automation boosts output and mesh accuracy.

2. Technology In-Depth: Manufacturing Process & Chain Link Fence Machine Technical Parameters

Manufacturing Workflow of Chain Link Fence Machine

- Wire Preparation – (Material: Galvanized steel, PVC-coated steel)

- High-strength Q195, Q235, SS304 steel, diameter range: 1.8mm–4.5mm

- Meets ISO 16120-2 wire rod standards for mechanical properties

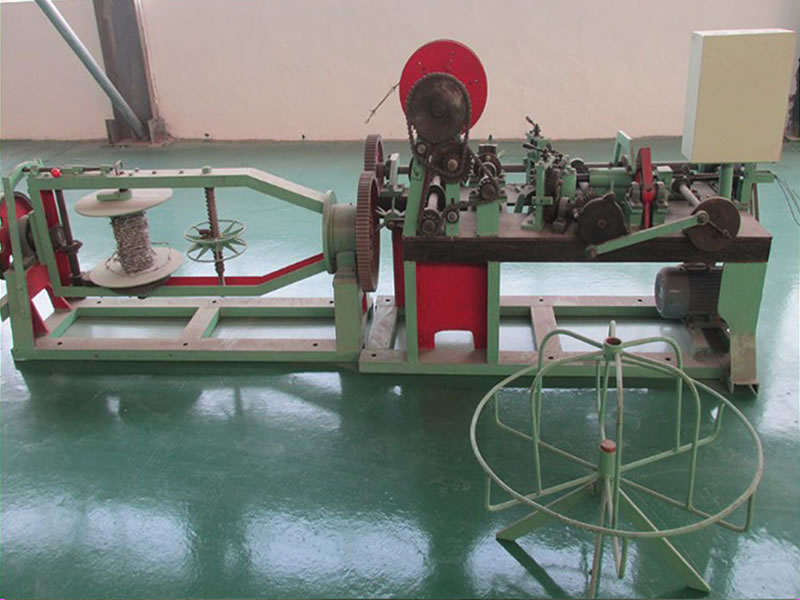

- CNC Wire Straightening – Ensures uniform mesh & eliminates manual error

- Wire Feeding – Precision servo motors automatically feed wire

-

Weaving/Twisting

- Automated vertical and spiral weaving using PLC controls

- Mesh size adjustable from 25x25mm to 100x100mm (±2mm tolerance)

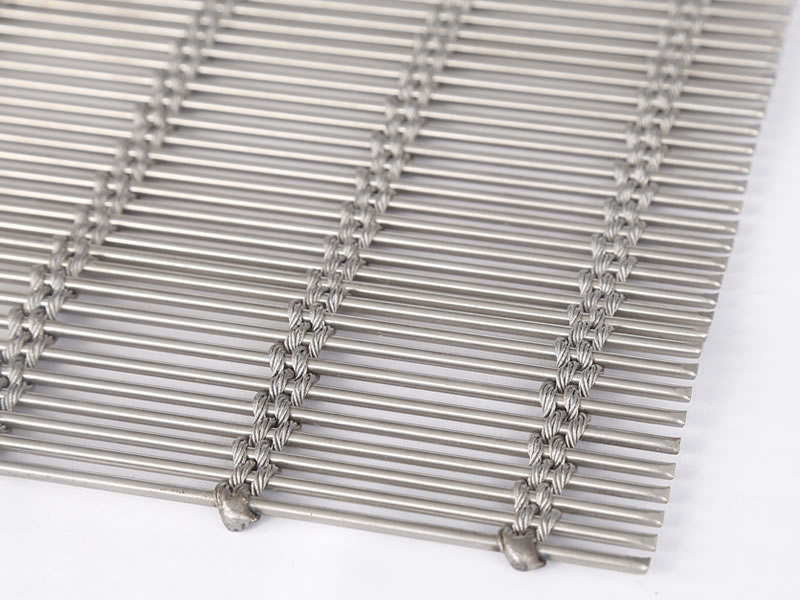

- Edge Locking & Cutting – Automated edge folding, optional barbed or knuckled finish

- Panel Rolling or Cutting – Custom length mesh panel output up to 30m per cycle

Diagram: Each major process above is governed by ISO 9001 QA + withstands continuous 24/7 industrial operation.

PLC-based chain link weaving machine for sale control box with real-time error correction system

Core Technical Parameters – Chain Link Fence Machine for Sale

| Parameter |

Specification (Standard Model) |

Premium Model |

Industry Benchmark |

| Wire Diameter |

1.8 – 4.5 mm |

1.8 – 5.0 mm |

1.6 – 5.5 mm |

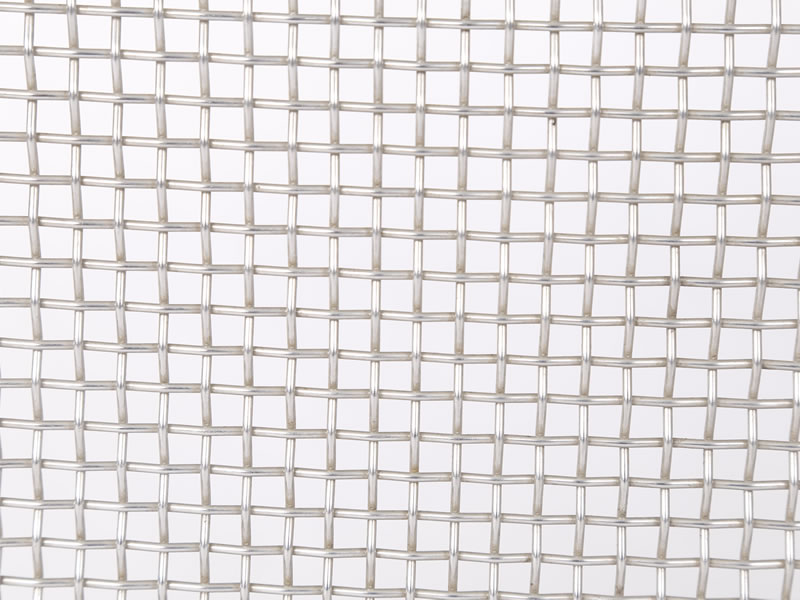

| Mesh Size |

25x25, 50x50, 75x75, 100x100 mm |

Customized, Min. 15x15mm |

20x20 – 100x100 mm |

| Max. Mesh Width |

2.5 m |

4.0 m / 6.0 m (customized) |

1.2 – 6.0 m |

| Output Speed |

75–120 m2/h |

120–180 m2/h |

90–160 m2/h |

| Material |

Galvanized/PVC Coated Steel |

Stainless Steel, Customized Coating |

Galvanized, SS304, PVC |

| Power |

6.0–8.5 kW |

8.5–12 kW |

5.8–14 kW |

| Control System |

PLC (Delta/Siemens), HMI Touch Screen |

Full Automation (Servo, remote) |

PLC, Manual/Auto |

| Standard Compliance |

ISO 9001, ISO 10223-6 |

ISO, CE, ANSI, SGS |

ISO, ASTM, CE |

Key Manufacturing Highlights

- Frame: Welded by Q235B steel profile, CNC laser cut, powder-coated anti-corrosive finish (ISO 2178 compliance)

- Drive Components: Precision CNC-machined gears, hardened with carbon nitriding, ensure 5+ year service with minimal wear

- Bearings: NSK/ZWZ ultra-low noise ball bearings – reduce vibration, enable 24/7 use

- Certification: Factory certified to ISO 9001:2015, products tested by SGS/CE/ANSI

- Quality Assurance: Each machine undergoes 128-point inspection, including mesh tension, alignment, and electrics

Material infeed & tensioning system: Stable wire feeding is the base of precise mesh forming.

3. Data Visualization: Chain Link Fence Machine Global Parameters & Market Stats

Parameter Distribution – Global Models (2024)

Machine manufacturers offering 2.0–4.5mm wire support dominate the market. Source: ExportHub, GlobalSpec, 2024.

Application Segment Share (2023) – Pie Chart

Construction and perimeter security are the top end-uses for chain link fence machines globally (Source: ResearchAndMarkets).

Output panel of chain link machine for sale, ready for industrial and sports enclosure installation

Output Speed Comparison by Brand (sq.m/h) – Line Chart

Top-tier machines reach up to 180m2/h with advanced servo control.

4. Chain Link Fence Machine for Sale – Manufacturer Comparison Table (2024)

| Brand |

Main Model |

Max. Mesh Width |

Wire Diameter |

Speed

(sq.m/h) |

PLC Brand / Control |

Certifications |

Warranty |

| Hebei Wire Mesh |

CLFM-4000S |

4.0 m |

1.8–5.0 mm |

120–180 |

Siemens/Delta, HMI+Remote |

ISO, CE, SGS |

3 years |

| Brand K (India) |

KLM-2530 |

2.5 m |

2.2–4.5 mm |

80–105 |

Siemens/Sanhe |

ISO 9001, CE |

1 year |

| Brand S (Turkey) |

CLS-PLUS |

3.0 m |

1.6–4.0 mm |

95–115 |

Delta |

ISO, CE |

2 years |

| Brand J (China) |

JM-LINK3500 |

3.5 m |

1.8–4.2 mm |

100–135 |

Local PLC |

ISO |

2 years |

| Brand M (Europe) |

M-LINK PRO |

2.4 m |

1.8–4.0 mm |

80–95 |

Siemens/HMI |

CE, SGS |

2 years |

Comparing industrial-grade chain link weaving machine for sale models: Modular designs for easy extension/upgrade.

5. Customization & Turnkey Solutions

- Customized Mesh Size: Any mesh opening from 15–100mm supported by specialized wire guides and custom code

- Panel Length: Automated cutting and rolling, programmable for 1.5–30m sections

- Materials: Support for galvanized, SS304, aluminum alloy, PVC-coated wire with corrosion protection (salt spray test: ≥500h, ISO 9227)

- Remote Monitoring: Wi-Fi/4G cloud diagnostics and software upgrades optional

- Power Spec: 220V/380V, 50~60Hz, customizable for local grid

Get a Quote for Chain Link Fence Machine for Sale →

6. Application Scenarios: Sector Advantages

- Construction Sites: Rapid fencing of perimeters, temporary worksites, and scaffolding

- Industrial Parks: Securing plants, warehouses, power stations

- Sports Facilities: Fencing for tennis, baseball, football, basketball courts (shock-resistant mesh)

- Oil, Gas & Chemical: Partitioning hazardous zones, explosion-proof fencing

- Urban Infrastructure: Roads, highways, railroad enclosures (anti-climb mesh possible)

- Agriculture: Livestock containment, field protection

Engineered fencing with chain link fence machine for sale: From highways to sports, quality is proven.

Advantages in Typical Applications

| Industry |

Key Benefit from Chain Link Fence Machine |

Data Point |

| Oil & Gas |

Corrosion-resistant mesh, anti-tamper design |

14% longer average service (ISO salt spray test) vs. manual |

| Construction |

Rapid production, varying mesh sizes |

2.7x output vs. semi-manual unit (as per field report 2023) |

| Sports |

Consistent impact absorption, safe edges |

80% playgrounds in Asia-Pacific use CNC-woven mesh* |

7. Client Experience: Application Cases & Feedback

Case 1: Oil Refinery (Saudi Arabia, 2022)

- Machine Model: CLFM-4000SR (Hebei Wire Mesh)

- Installed for: 5.4km of double-layer chain link security fencing

- Feedback: “Cycle time dropped by 32%. Wire tension accuracy meant less post-tension field work. Corrosive salt air? Mesh held up perfectly at 24 months!” (QA Engineer, S*** Refining)

Case 2: Stadium Fencing (Malaysia, 2023)

- Machine Model: CLFM-2500S

- Output: 13,000 m2 of 50x50mm tennis mesh, in 7 weeks

- Feedback: “Mesh panels all uniform, tolerances tight. PLC interface was simple for our new staff. Very satisfied.” (Project Manager, Y*** Engineering)

Case 3: Highway Project (Turkey, 2021)

- Machine Model: Custom 3m width unit

- Result: Delivered 8km fencing, 97.5% installation with zero field weld repair required

8. FAQ – Chain Link Fence Machine for Sale Technical & Procurement Questions

Q1: What materials can the chain link fence machine for sale process?

A: Most machines process galvanized steel, PVC-coated steel, aluminum alloy, and even stainless steel wire (Q195/Q235/SS304); confirm wire duct size for each type.

Q2: What is the standard mesh size and can it be adjusted?

A: Standard mesh aperture: 25x25mm to 100x100mm (adjustable). Premium CNC models support as fine as 15mm mesh via touch screen settings.

Q3: How is edge locking performed, and does it comply with safety standards?

A: Edge locking is automated (knuckled, barbed, twisted ends), compatible with international safety standards (ASTM A392, ISO 10223-6, EN 10244).

Q4: What is the installation standard for the machine itself?

A: Install on level, vibration-free floor with bolted anchors. Electrical setup per local codes. Machines comply with ISO 12100 machine safety & CE machinery directive.

Q5: What about maintenance and spare parts support?

A: All wear parts (gears, blades, PLC relays, guides) are standard modular and available globally. Service guides & video support included in all shipments.

Q6: What is the mesh wire's anti-corrosion standard?

A: ISO 9227 or ASTM B117 salt spray corrosion test. PVC-coated wire mesh can pass 500 hours at 35°C/5% NaCl with no rust penetration.

Q7: What is the power requirement and operational noise?

A: Most CNC chain link machines require 6–12kW, 3 phase/50-60Hz. Noise is typically <81dB (measured at 1m distance).

9. Delivery, Warranty & Customer Support

- Delivery Time: Standard machines: 15–25 days after advance payment. Custom models (wider mesh, special wire): 30–45 days.

- Warranty: 12–36 months (brand/model dependent). Electronic, PLC, and wiring: up to 2 years. Mechanical frame: up to 5 years optional.

- Onsite Setup: Factory technicians available globally, typical setup 3–5 days, remote video commissioning free.

- Spare Parts: All standard spares shipped with machine, supported for 10+ years inventory.

- After-sales: 24×7 technical hotline, local agents in >17 countries, remote PLC diagnostics & firmware upgrades.

All compliance certificates (ISO, CE, SGS) and detailed testing sheets provided with shipment for your customs and regulatory needs.

10. Why Choose Hebei Wire Mesh Chain Link Fence Machine for Sale?

- Decades of production & export. Global enterprise clients (Petronas, Vinci, Total, Sinopec, L&T)

- Third-party certified: ISO 9001, SGS, CE, ANSI

- Proven in harsh climates: machines running 24/7 in Middle East, Southeast Asia, Russia, Africa

- Technology-leading R&D for mesh accuracy, energy and wire cost saving

- Multi-language support, real project references, lifetime remote support

Explore Chain Link Fence Machine for Sale Options →

11. References & Further Reading:

-

Mordor Intelligence: Fencing Market Trend Report 2024

-

ResearchAndMarkets: Global Chain Link Fence Market Report 2023

-

ASTM A392: Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric

-

ISO 10223-6: Steel wire and wire products — Fences

-

Metalworking World Forum: Choosing Chain Link Fence Machines (2023)

*Industry insights sourced from client feedback, ASTM/ISO documentation, and international construction case studies. For the best chain link fence machine for sale solution, always verify credentials, service, and certifications!