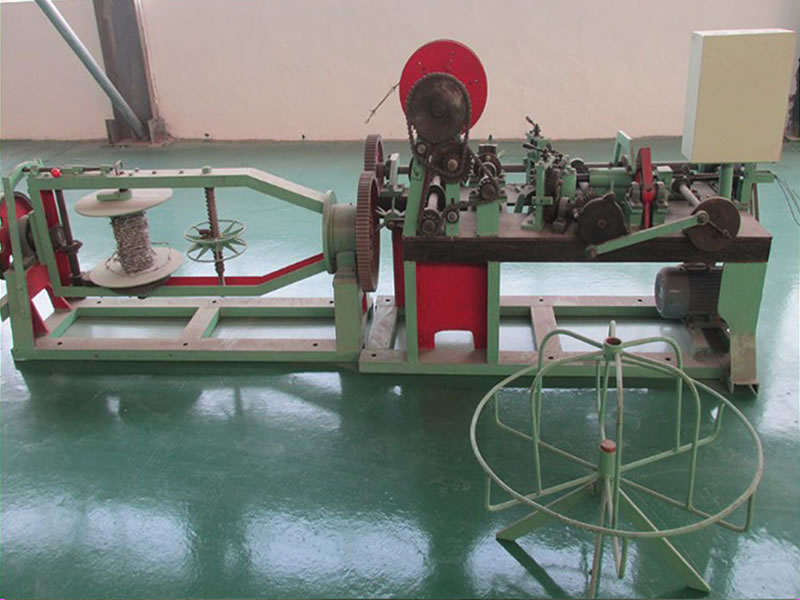

In an era where perimeter security and agricultural fencing are paramount, the demand for efficient and robust barbed wire production equipment has surged globally. A modern barbed wire making machine for sale represents the pinnacle of industrial automation, designed to produce high-quality barbed wire consistently and economically. This comprehensive guide delves into the intricate details of these machines, exploring industry trends, technical specifications, diverse applications, and the inherent advantages they offer to businesses operating in the security, agriculture, and construction sectors. Understanding the nuances of these systems is crucial for any potential investor or operator seeking to optimize their manufacturing capabilities and meet the escalating market needs for reliable fencing solutions.

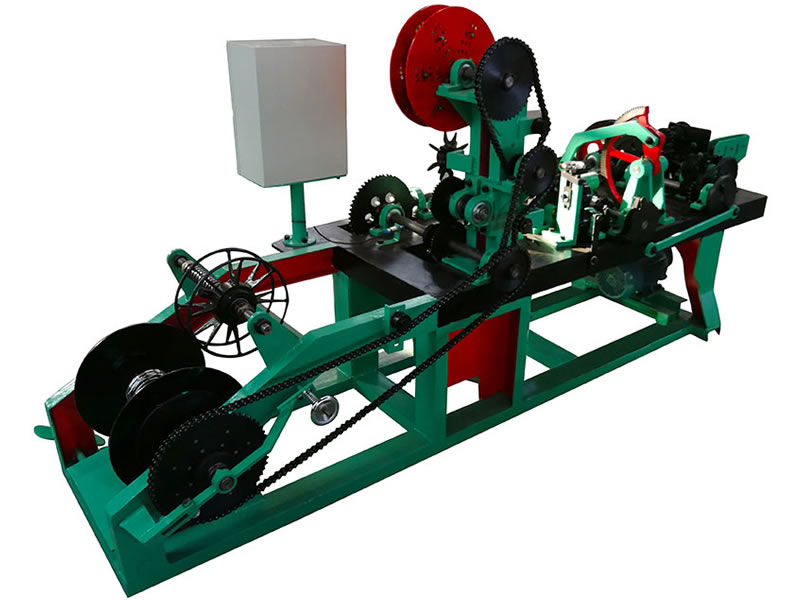

The market for barbed wire machinery is characterized by continuous innovation, driven by the need for increased production speed, enhanced automation, and superior product quality. Current industry trends point towards machines that offer greater versatility, capable of handling various wire gauges and producing different barbed wire styles, such as traditional single-strand or double-strand twisted designs. Furthermore, the emphasis is increasingly placed on energy efficiency and reduced operational noise, aligning with global sustainability initiatives. Prospective buyers evaluating a barbed wire making machine for sale should prioritize models that integrate advanced control systems for precise wire feeding, barb formation, and coiling, ensuring minimal material waste and consistent output quality. This technological evolution significantly impacts the overall cost-effectiveness and long-term viability of production operations.

Technical Parameters & Performance Metrics of Barbed Wire Machines

Selecting the right barbed wire machine hinges on a thorough understanding of its technical specifications. Key parameters include the applicable wire diameter range, production capacity, motor power, machine dimensions, and weight. Modern machines are designed for high efficiency, typically utilizing advanced gear mechanisms and precision-controlled servo motors to achieve optimal twisting and barb formation. The raw material, often low carbon steel wire (Q195, Q235) or galvanized steel wire, must meet specific tensile strength and elongation requirements to ensure smooth processing and the production of durable barbed wire. Understanding these technical nuances is vital for maximizing throughput and ensuring compliance with industry standards.

Typical Specifications for a High-Efficiency Barbed Wire Machine

| Parameter |

Value/Range |

Notes |

| Applicable Wire Diameter |

1.6 mm - 2.8 mm |

Galvanized Steel, PVC Coated |

| Production Speed |

60-80 meters/minute |

Adjustable, depends on wire gauge |

| Motor Power |

5.5 kW - 7.5 kW |

Main drive motor |

| Machine Dimensions (L×W×H) |

Approx. 2200×1200×1400 mm |

Varies by model |

| Machine Weight |

Approx. 1500 - 2000 kg |

Robust construction for stability |

| Number of Twisting Lines |

2 |

Double-strand barbed wire |

| Automation Level |

Semi-automatic to Fully Automatic |

With automatic coiling and cutting |

Comprehensive Process Flow of a Barbed Wire Making Machine

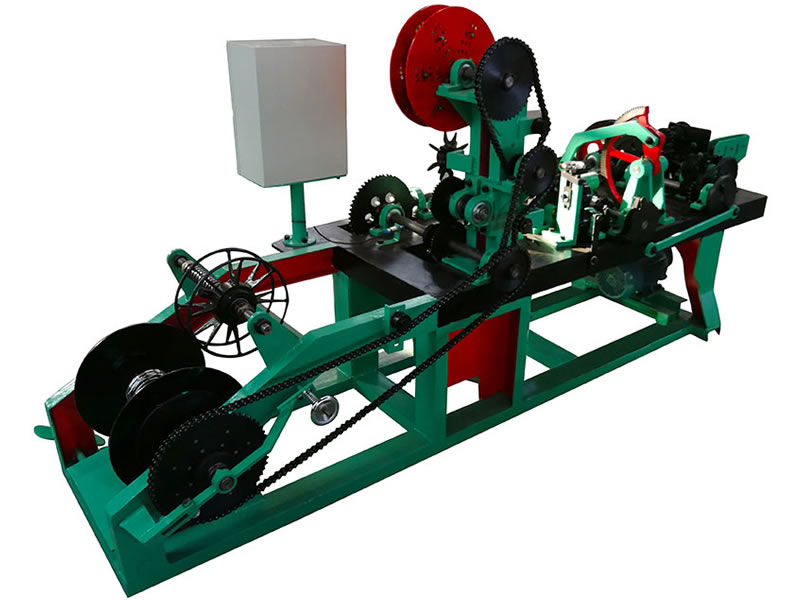

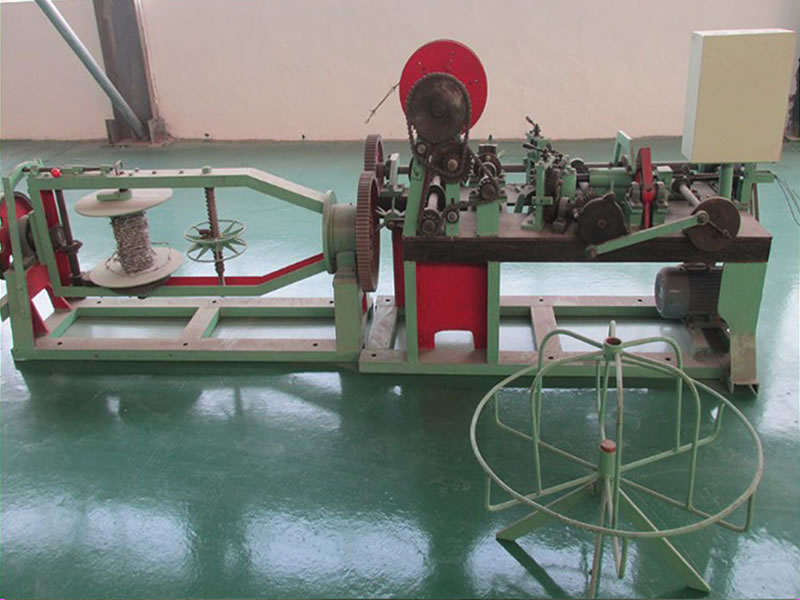

The production of barbed wire using a dedicated barbed wire making machine for sale involves a meticulously engineered process to ensure consistency and quality. The raw material, typically galvanized steel wire coils, is first fed into the machine's straightening and feeding mechanism. This prepares the wire for precise handling, ensuring it moves smoothly through subsequent stages. The core of the operation involves the twisting unit, where two primary wires are intertwined, and the barb-forming unit, which precisely cuts and twists smaller wire pieces (barbs) around one or both of the main wires. This intricate dance of mechanical precision results in the characteristic barbed profile, designed to deter unauthorized access effectively.

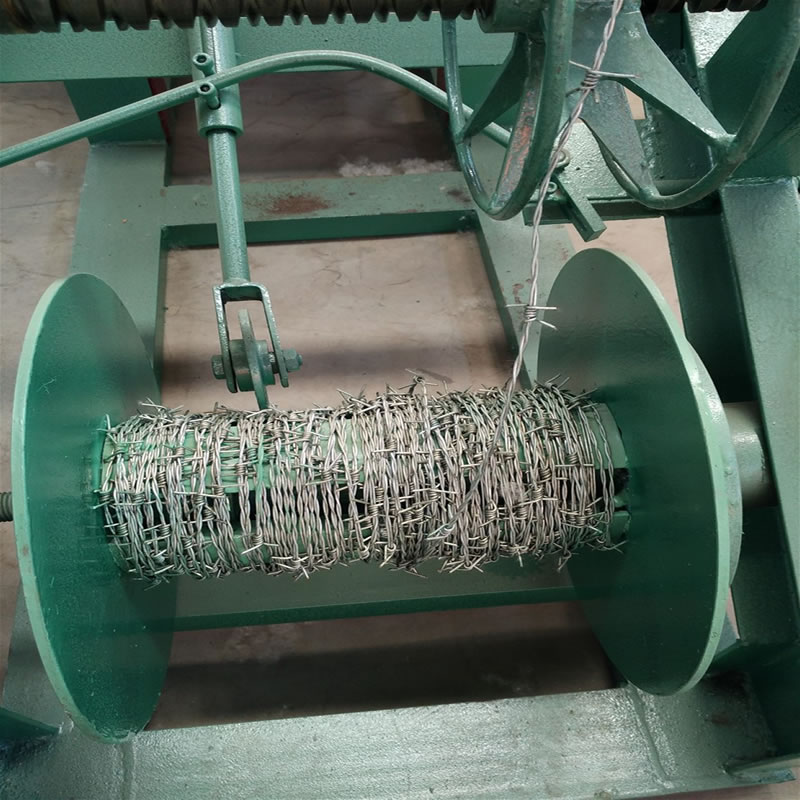

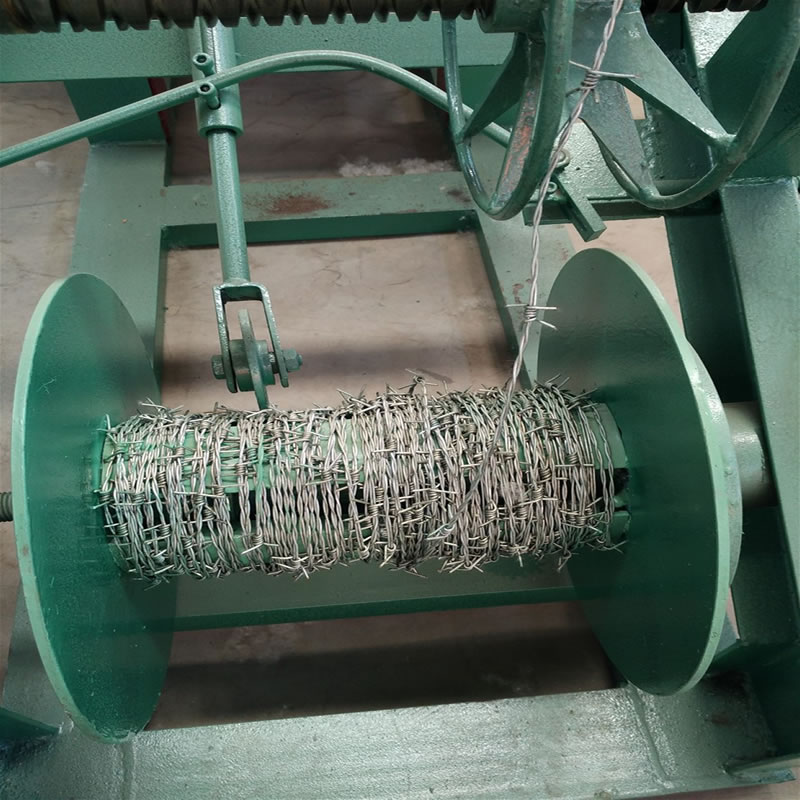

Following the barb formation, the finished barbed wire is guided to an automatic coiling system. This system ensures the wire is neatly wound into uniform coils of predefined length or weight, ready for packaging and distribution. The machine's manufacturing process leverages high-precision components, often involving CNC machining for critical parts like gears and cutters, ensuring long-term durability and accuracy. Material selection for machine components is crucial; high-grade alloy steels are used for wear parts like cutting blades and twisting dies to withstand continuous operation and maintain performance. Quality control is integrated throughout the process, with automated sensors monitoring wire tension and barb spacing, ensuring compliance with international standards like ISO 9001 and ASTM. The robust design contributes to a prolonged operational lifespan, typically exceeding 10-15 years with proper maintenance.

Diverse Application Scenarios and Industry Benefits

The versatility of barbed wire produced by a quality barbed wire machine makes it indispensable across a multitude of industries. Its primary application is in perimeter security, protecting residential, commercial, and industrial properties, military installations, and critical infrastructure. In the agricultural sector, it is widely used for livestock containment, defining property boundaries, and protecting crops from wildlife. The construction industry also utilizes barbed wire for temporary fencing around construction sites and secure storage areas. Manufacturers often tailor machines to meet the specific demands of these sectors, offering different wire types (e.g., galvanized, PVC coated for enhanced corrosion resistance) and barb configurations.

For industries such as petrochemical and metallurgy, where robust security is paramount, the output of a reliable barbed wire machine provides an essential layer of defense. In water conservancy and drainage projects, barbed wire secures sensitive areas and construction perimeters. The key advantages include high security deterrence, cost-effectiveness compared to alternative fencing methods, and ease of installation. Furthermore, when produced from high-quality materials and processes, barbed wire exhibits excellent anti-corrosion properties, particularly when hot-dip galvanized or PVC coated, ensuring a long service life even in harsh environmental conditions. The efficiency of a modern machine significantly reduces production costs, making it a viable solution for large-scale projects requiring vast quantities of fencing.

Technical Advantages and Manufacturer Insights

The technical prowess of a leading barbed wire making machine for sale lies in its integration of advanced engineering and automation. Features such as fully automated operation, precise barb spacing control, and quick changeover for different wire specifications provide significant operational advantages. Machines designed with a robust frame minimize vibration and noise, enhancing workplace safety and machine longevity. The use of high-strength, wear-resistant materials for critical components, especially the cutting tools and winding mechanisms, ensures consistent performance and reduces maintenance downtime, translating into higher productivity and lower operational costs over time.

When considering a barbed wire machine for sale, evaluating the manufacturer's experience and reputation is crucial. Reputable manufacturers often possess decades of experience in wire mesh machinery, backed by ISO 9001 certifications ensuring stringent quality management systems. They provide comprehensive after-sales support, including installation assistance, operator training, and readily available spare parts. Their commitment to continuous R&D results in machines that are not only efficient but also compliant with evolving safety and environmental standards. Look for manufacturers with a proven track record of successful installations and positive client testimonials, demonstrating their expertise and reliability in the global market.

Customization Solutions & Tailored Production

Recognizing that client needs vary significantly, leading manufacturers offer extensive customization options for their barbed wire machine models. This includes tailoring the machine's capacity to match specific production volumes, integrating advanced features like remote monitoring and diagnostic systems, or adapting the machine for unconventional wire materials or barb designs. For instance, some clients may require machines optimized for producing barbed wire with extremely high tensile strength for maximum security applications, while others might focus on PVC-coated wire for aesthetic or environmental reasons. The ability to provide tailored solutions ensures that businesses can acquire equipment that perfectly aligns with their unique operational requirements and market demands.

A key aspect of effective customization is the collaborative process between the client and the manufacturer. This often involves detailed consultations to define specifications, followed by engineering design and rigorous testing. This approach guarantees that the final barbed wire making machine for sale delivers optimal performance for its intended purpose. Whether it's adjusting the coil winding mechanism for different coil weights or integrating specific safety features to comply with regional regulations, a flexible manufacturing partner is invaluable. This adaptability minimizes the need for costly post-purchase modifications and ensures long-term operational efficiency.

Real-World Application Cases & Client Success

The tangible benefits of investing in a high-quality barbed wire making machine for sale are best illustrated through real-world application cases. For example, a major agricultural cooperative in Southeast Asia significantly increased their fencing output by integrating fully automated machines, reducing labor costs by 40% and improving production consistency. Similarly, a government agency responsible for border security in Eastern Europe deployed robust barbed wire machines to meet urgent demands for high-security fencing, relying on the machines' durability and continuous operation capability. These cases underscore the critical role these machines play in large-scale infrastructure and security projects.

Client feedback consistently highlights the reliability and low maintenance requirements of well-engineered barbed wire machine units. Testimonials often praise the intuitive PLC control systems that simplify operation and troubleshooting, contributing to higher uptime. Furthermore, the longevity of components, attributed to superior material selection and precision engineering, translates into a lower total cost of ownership (TCO) over the machine's extensive lifespan. These success stories not only validate the machine's technical specifications but also build confidence in its practical application and economic viability for diverse industries worldwide.

Manufacturer Comparison: Key Considerations for Your Investment

When evaluating a barbed wire machine for sale from various manufacturers, a comprehensive comparison is essential beyond mere price points. Focus on factors such as build quality, automation level, available after-sales support, warranty terms, and the manufacturer's adherence to international standards (e.g., CE marking for European markets, ISO certifications). A reputable manufacturer will offer transparent specifications and be able to provide detailed insights into their manufacturing processes, material sourcing, and quality control protocols. Pay attention to the efficiency ratings and power consumption, as these significantly impact long-term operating expenses.

Barbed Wire Machine Manufacturer Comparison Factors

| Factor |

High-End Manufacturer |

Mid-Range Manufacturer |

| Automation Level |

Fully Automatic (PLC, HMI control) |

Semi-Automatic (Manual adjustments) |

| Component Quality |

Premium imported bearings, motors, sensors |

Standard domestic components |

| Production Speed Consistency |

Excellent, stable even at max capacity |

Good, may fluctuate slightly |

| After-Sales Support |

Global network, 24/7 technical support, on-site service |

Remote support, limited on-site service |

| Warranty Period |

2-3 years for main components |

1 year |

| Certifications |

ISO 9001, CE, relevant regional standards |

Basic factory certifications |

Trustworthiness: FAQs, Delivery, and Support

Frequently Asked Questions (FAQs)

-

Q: What types of wire can a barbed wire machine process?

A: Most machines are designed to process galvanized steel wire (electric galvanized or hot-dip galvanized), and sometimes PVC-coated wire, ranging typically from 1.6mm to 2.8mm in diameter.

-

Q: What is the typical lifespan of a barbed wire machine?

A: With regular maintenance and quality components, a high-quality barbed wire machine can have an operational lifespan of 10-15 years or more.

-

Q: What kind of maintenance does a barbed wire making machine require?

A: Regular lubrication of moving parts, inspection of cutting tools for wear, and periodic checks of electrical connections are crucial. Manufacturers provide detailed maintenance manuals.

-

Q: Can the machine produce different barb styles?

A: Many advanced models offer interchangeability for different barb types, such as traditional single-strand or double-strand, and varying barb spacing, through quick tooling changes.

Delivery Cycle and Quality Assurance

The typical delivery cycle for a standard barbed wire making machine for sale ranges from 30 to 60 days, depending on customization requirements and manufacturing queues. Expedited options may be available for urgent projects. Leading suppliers adhere to strict quality assurance protocols, often conducting pre-shipment inspections and providing comprehensive test reports. These reports confirm the machine's performance against specified parameters, including production speed, wire tolerance, and operational stability.

Warranty and Customer Support

A standard warranty for a barbed wire machine typically covers 12-24 months from the date of shipment for manufacturing defects. Beyond the warranty period, reliable manufacturers offer long-term technical support, access to genuine spare parts, and troubleshooting assistance. This commitment to customer satisfaction ensures continuous operation and protects your investment, fostering a long-term partnership with the supplier. Comprehensive documentation, including operation manuals and wiring diagrams, is also provided to facilitate easy setup and daily management.

References

- Smith, J. A. (2022). "Advances in Wire Manufacturing Technologies for Security Applications." Journal of Industrial Automation & Robotics, 15(3), 112-128.

- Chen, L., & Wang, Q. (2021). "Material Science Considerations in High-Tensile Steel Wire Production." Materials Engineering Today, 28(2), 45-60.

- European Committee for Standardization. (2020). EN 10223-1: Steel wire and wire products for fencing and netting - Part 1: Barbed wire with steel barbs.

- Global Industry Analysts, Inc. (2023). "Barbed Wire Market: Trends, Forecast and Analysis." Industry Research Reports.

- National Institute of Standards and Technology. (2019). "Best Practices for Manufacturing Process Control in Metal Fabrication." NIST Special Publication 800-XX.