In the vast landscape of industrial materials, the demand for high-performance, durable, and cost-effective solutions is ever-growing. Among these, Black Epoxy Coated Wire Mesh stands out as a superior choice, offering unparalleled corrosion resistance and aesthetic appeal. This comprehensive guide delves into the intricacies of this advanced material, exploring its technological underpinnings, diverse applications, and the significant advantages it brings to various sectors.

Our commitment to excellence and innovation positions us at the forefront of the wire mesh industry. With decades of expertise, we understand the critical needs of our clients, providing solutions that not only meet but exceed industry standards. This deep dive aims to equip you with all the necessary knowledge, from material science to practical implementation, reinforcing our position as a trusted authority in the field.

Global Trends and Market Dynamics of Coated Wire Mesh

The global market for coated wire mesh, particularly epoxy-coated variants, is experiencing robust growth driven by increasing demand from construction, automotive, agriculture, and filtration industries. According to recent market analyses, the global industrial wire mesh market size was valued at USD 5.9 billion in 2022 and is projected to reach USD 8.5 billion by 2030, growing at a CAGR of 4.7% from 2023 to 2030. This growth is significantly influenced by the rising need for corrosion-resistant materials in harsh environments and the emphasis on sustainable, long-lasting infrastructure.

The Asia-Pacific region, spearheaded by China and India, dominates this market due to rapid industrialization and urbanization. Europe and North America also maintain significant shares, driven by stringent quality standards and innovation in material science. The trend leans towards products offering enhanced durability, reduced maintenance, and environmental compliance, where Black Epoxy Coated Wire Mesh perfectly fits the bill.

Technological advancements in coating processes, such as electrostatic powder coating, are enabling more uniform and resilient finishes, further boosting the adoption of epoxy-coated mesh. Industries are increasingly seeking materials that can withstand chemical exposure, extreme temperatures, and mechanical stress, making epoxy coatings an attractive solution for critical applications.

Technical Parameters and Specifications of Black Epoxy Coated Wire Mesh

Understanding the technical specifications of Black Epoxy Coated Wire Mesh is crucial for its optimal application. This product is typically manufactured from low carbon steel wire, galvanized iron wire, or even stainless steel wire, which then undergoes a specialized epoxy coating process. The black epoxy coating provides a durable, smooth, and aesthetically pleasing finish that offers superior protection against corrosion and abrasion.

Key Parameters:

- Material: Low Carbon Steel, Galvanized Steel, Stainless Steel (e.g., SS304, SS316). The base wire material determines the fundamental mechanical properties.

- Wire Diameter: Ranging from 0.4mm to 2.5mm, depending on the required strength and application. Measured in SWG (Standard Wire Gauge) or millimeters.

- Mesh Count (Mesh Per Inch): From 4 mesh to 60 mesh, indicating the number of openings per linear inch. Higher mesh counts mean finer filtration capabilities.

- Weaving Pattern: Plain weave, twill weave, Dutch weave, or welded mesh. Plain weave is the most common for its stability and straightforward construction.

- Coating Thickness: Typically 0.15mm to 0.3mm (150-300 microns), ensuring comprehensive coverage and enhanced protection. Thicker coatings generally offer superior corrosion resistance.

- Open Area: The percentage of open space in the mesh, influencing flow rate and filtration efficiency. Calculated based on wire diameter and mesh count.

- Tensile Strength: Measures the maximum stress the wire mesh can withstand before breaking, typically ranging from 450-650 MPa for steel wires.

- Temperature Resistance: The epoxy coating can withstand temperatures generally up to 120°C (250°F) continuously, with intermittent exposure to higher temperatures possible.

- Corrosion Resistance: Excellent resistance to acids, alkalis, salts, and various chemicals, as demonstrated by accelerated salt spray tests (e.g., exceeding 1000 hours in ASTM B117).

Typical Product Specifications Table:

| Parameter |

Typical Range/Value |

Unit |

Notes |

| Base Material |

Low Carbon Steel / Galvanized Steel |

- |

Also available in SS grades for specific applications |

| Wire Diameter |

0.5 - 1.2 |

mm |

Customizable based on strength requirements |

| Mesh Count |

8 - 40 |

Mesh per Inch |

Influences filtration and flow characteristics |

| Roll Width |

0.914 - 1.5 |

m |

Standard widths, custom available |

| Roll Length |

15 - 30 |

m |

Standard lengths |

| Coating Thickness |

180 - 250 |

microns |

Ensures robust corrosion protection |

| Operating Temperature |

-40 to +120 |

°C |

Continuous operation; short-term higher possible |

| Salt Spray Resistance (ASTM B117) |

>1000 |

Hours |

Excellent resistance to corrosive environments |

| UV Resistance |

Good |

- |

Maintains color and integrity in sunlight |

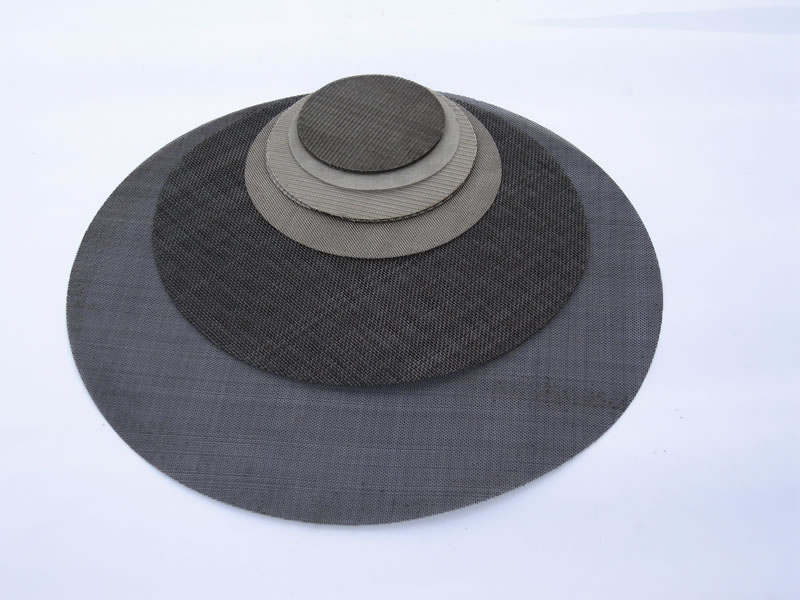

The Meticulous Manufacturing Process of Black Epoxy Coated Wire Mesh

The superior performance of Black Epoxy Coated Wire Mesh is a direct result of a meticulously controlled manufacturing process. Unlike traditional casting or forging, wire mesh production involves wire drawing, weaving/welding, and then a sophisticated coating procedure. Here’s a detailed breakdown of the typical steps involved:

Process Flow Diagram (Conceptual Textual Representation):

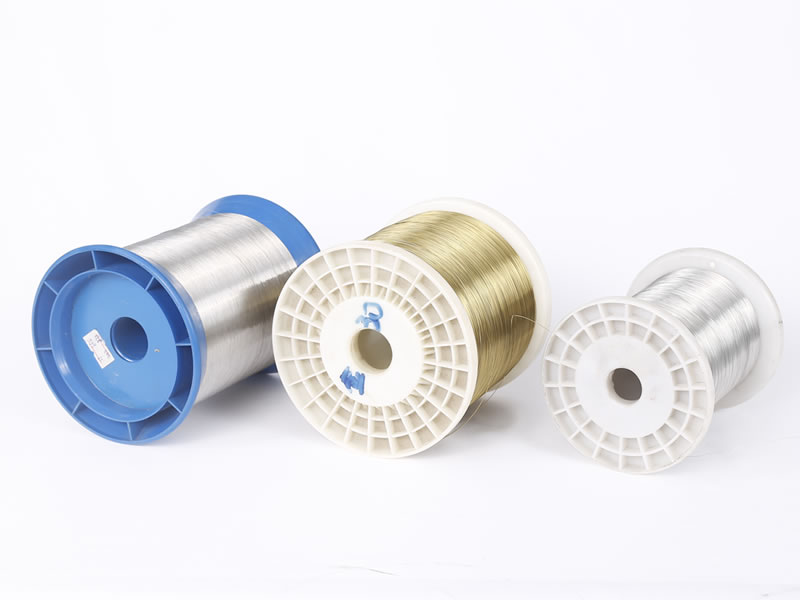

1. Wire Material Selection & Drawing

High-quality raw wire coils (low carbon steel, galvanized steel, or stainless steel) are selected based on end-use requirements. These wires are then drawn through a series of dies to achieve the precise desired wire diameter.

↓

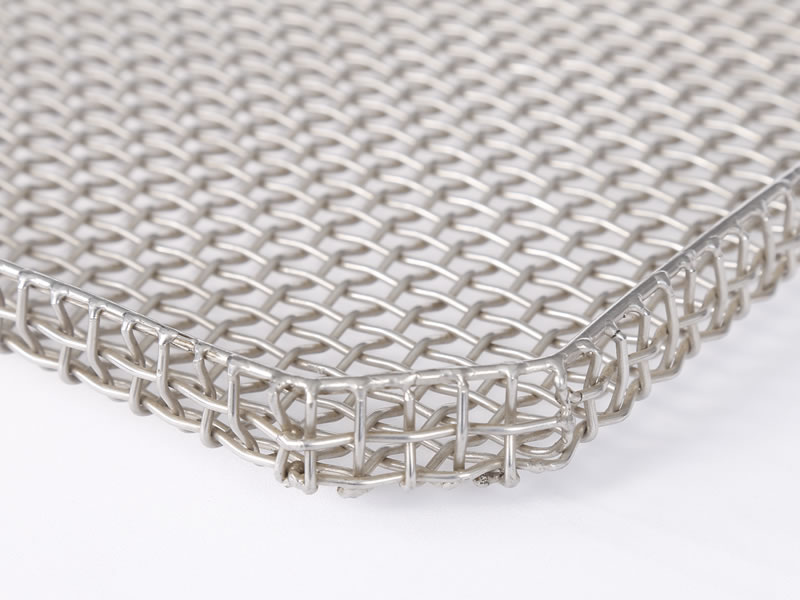

2. Weaving or Welding

The drawn wires are then fed into automated weaving looms or welding machines. For woven mesh, warp and weft wires are interlaced to form the desired mesh pattern (e.g., plain weave). For welded mesh, wires are precisely resistance-welded at their intersections, creating a rigid structure.

↓

3. Surface Preparation (Cleaning & Pre-treatment)

This is a critical stage for coating adhesion. The woven or welded mesh undergoes thorough cleaning, typically involving degreasing, acid pickling to remove rust and scale, and rinsing. This is followed by a phosphating or chromate conversion coating to create an ideal surface for epoxy adhesion. Proper surface preparation ensures maximum bond strength and long-term durability of the coating.

↓

4. Electrostatic Powder Coating (Epoxy Application)

The prepared mesh is then moved to an electrostatic powder coating booth. Finely ground epoxy powder particles are electrostatically charged and sprayed onto the grounded mesh. The electrostatic attraction ensures a uniform and comprehensive coating, even on complex mesh geometries. This method minimizes waste and ensures excellent coverage.

↓

5. Curing (Baking)

After powder application, the coated mesh enters a high-temperature curing oven. The heat melts the epoxy powder, causing it to flow out and form a continuous, smooth, and highly durable film that bonds strongly to the wire surface. The curing temperature and duration are precisely controlled to achieve optimal coating properties.

↓

6. Cooling & Quality Control

The mesh exits the oven and is allowed to cool. Comprehensive quality control checks are performed, including visual inspection for coating uniformity, adhesion tests (e.g., cross-hatch test, bend test), coating thickness measurement (using magnetic or eddy current gauges), and occasionally salt spray tests for corrosion resistance (per standards like ASTM B117 or ISO 9227). Compliance with international standards such as ISO 9001 for quality management is strictly adhered to, ensuring a consistent and reliable product.

↓

7. Packaging & Dispatch

Finally, the inspected and approved Black Epoxy Coated Wire Mesh is carefully rolled or cut into sheets, then packaged to prevent damage during transit, ready for shipment to clients worldwide.

This detailed process ensures that each batch of Black Epoxy Coated Wire Mesh meets stringent quality specifications and delivers exceptional performance in its intended application.

Diverse Application Scenarios and Industry Advantages

Black Epoxy Coated Wire Mesh boasts a versatile range of applications across numerous industries, primarily due to its exceptional resistance to corrosion, chemicals, and abrasion, coupled with its aesthetic appeal. Its advantages often translate into significant long-term cost savings through reduced maintenance and extended product life.

Key Applicable Industries:

- Petrochemical Industry: Used in filtration systems for corrosive liquids, catalyst support, and protective barriers in processing plants where resistance to hydrocarbons, acids, and alkalis is paramount. Its anti-corrosive properties ensure operational safety and longevity of equipment.

- Metallurgy & Mining: Employed in screening and sieving applications for minerals, ore separation, and protective guarding around heavy machinery. The epoxy coating resists abrasive wear and acidic environments often found in mining operations.

- Water Treatment & Drainage Systems: Ideal for wastewater filtration, storm drain covers, sediment removal, and general water management systems. The coating prevents rust and clogging from waterborne contaminants, enhancing system efficiency and reducing maintenance needs.

- Automotive Industry: Used in radiator grilles, air filters, oil filters, and speaker grilles. Its durable finish and corrosion resistance are vital for components exposed to harsh road conditions and fluids. The black finish offers a sleek look.

- Construction & Architecture: Applied in infill panels for railings, security screens, decorative facades, and anti-climb barriers. Its structural integrity combined with anti-corrosion properties makes it suitable for outdoor and exposed applications.

- Agriculture: Utilized in animal enclosures, crop protection, and ventilation screens. The mesh resists rust from moisture and animal waste, offering a long-lasting and safe solution.

- HVAC & Air Filtration: Critical component in various air filtration units, including pre-filters and insect screens, preventing particulate matter and pests while ensuring optimal airflow without corrosion.

- Electronic and Electrical Enclosures: Used for EMI/RFI shielding, ventilation, and protective covers for sensitive electronic components, where a non-conductive, corrosion-resistant, and aesthetically pleasing material is required.

Technical Advantages in Application:

- Superior Corrosion Resistance: The epoxy coating provides an excellent barrier against rust and oxidation, outperforming galvanized and bare steel meshes in corrosive environments. This extends the service life significantly.

- Chemical Resistance: Exhibits high resistance to a wide range of chemicals, including acids, alkalis, salts, and oils, making it suitable for industrial processes with chemical exposure.

- Abrasion Resistance: The tough epoxy layer protects the underlying wire from wear and tear, making it durable in applications involving friction or impact.

- Aesthetic Appeal: The uniform black finish offers a clean, professional, and modern look, desirable for architectural and consumer product applications.

- Electrical Insulation: Epoxy is an electrical insulator, which can be advantageous in applications where conductivity needs to be minimized or where accidental short circuits must be prevented.

- Reduced Maintenance: Due to its high durability and corrosion resistance, Black Epoxy Coated Wire Mesh requires less frequent cleaning and replacement, leading to significant operational cost savings over its lifespan.

- Long Service Life: Designed for longevity, this mesh offers an impressive service life, often exceeding 15-20 years in typical outdoor conditions, depending on the specific environment and maintenance. This is particularly true when compared to non-coated or poorly coated alternatives.

Choosing Your Partner: Manufacturer Comparison and Quality Assurance

Selecting the right manufacturer for Black Epoxy Coated Wire Mesh is paramount to ensuring product quality, consistency, and timely delivery. While many suppliers exist, significant differences can be found in their manufacturing processes, quality control, and customer service. Here’s a comparative perspective on what sets a leading manufacturer apart:

Key Differentiators in Manufacturer Comparison:

| Feature |

Leading Manufacturer (e.g., Hebei Wire Mesh Co.) |

Typical Supplier |

| Raw Material Sourcing |

Premium grade low carbon steel/galvanized wire from verified mills; Material Test Certificates (MTCs) available. |

Variable quality, often from multiple, unverified sources. |

| Manufacturing Process |

Automated weaving/welding lines; Dedicated, climate-controlled surface preparation & electrostatic coating facilities. Precision curing ovens. |

Manual or semi-automated processes; Less controlled environments leading to inconsistent coating. |

| Coating Adhesion & Thickness |

Consistent coating thickness (e.g., 200±20 microns) and superior adhesion due to rigorous pre-treatment and electrostatic application. ISO 2409 (Cross-cut test) adherence. |

Variations in thickness; poor adhesion due to inadequate surface prep. |

| Quality Control & Standards |

Multi-stage QC (pre-treatment, post-coating, final inspection); Adherence to ISO 9001:2015, ASTM B117 (Salt Spray Test), and specific client standards. In-house testing lab. |

Minimal QC; reliant on supplier certificates; less stringent testing. |

| Product Lifespan |

Guaranteed longer service life (e.g., 15+ years in standard outdoor conditions) due to superior coating. |

Shorter, unpredictable lifespan; premature corrosion. |

| Customization Capabilities |

Extensive customization for mesh count, wire diameter, roll dimensions, and specific epoxy formulations. Engineering support. |

Limited customization; standard sizes only. |

| Technical Support & After-Sales |

Dedicated engineering team; comprehensive post-sales support; warranty and guarantee. |

Limited or no technical support; "as-is" sales. |

| Certifications & Compliance |

ISO certified (e.g., ISO 9001, ISO 14001); compliance with specific industry regulations (e.g., REACH, RoHS where applicable). |

Few or no internationally recognized certifications. |

| Experience & Authority |

Decades of industry experience, established reputation, strong client testimonials, published case studies. |

Newer entrants or smaller operations with less proven track record. |

Our company prides itself on adhering to the highest global standards. We are ISO 9001:2015 certified, reflecting our commitment to a robust quality management system. Our products consistently pass stringent third-party tests, including ASTM B117 for salt spray resistance, often exceeding 1000 hours without significant corrosion. This level of quality assurance is a testament to our expertise and trustworthiness, built on over two decades of experience in the wire mesh industry.

Tailored Solutions: Customization and Engineering Support

Recognizing that every industrial application has unique requirements, we offer extensive customization options for Black Epoxy Coated Wire Mesh. Our engineering team works closely with clients to develop tailored solutions that perfectly match their specific needs, optimizing performance and cost-effectiveness.

Customization Parameters Include:

- Wire Material: Selection of specific base wire materials (e.g., different grades of stainless steel like SS304L, SS316L for enhanced chemical resistance) to suit the environment.

- Wire Diameter & Mesh Count: Precise adjustment of wire thickness and mesh density to achieve desired filtration rates, structural strength, or open area percentages.

- Weaving/Welding Pattern: Beyond standard plain weave, options like twill weave for finer filtration, or welded mesh for increased rigidity, can be provided.

- Coating Thickness & Formulation: Customization of epoxy coating thickness for enhanced protection in extremely aggressive environments, or specific epoxy formulations for unique chemical resistance requirements.

- Roll/Sheet Dimensions: Production of custom widths and lengths of rolls, or pre-cut sheets to minimize waste and facilitate installation at the client's site.

- Fabrication Services: Beyond the mesh itself, we can provide additional fabrication services such as cutting, bending, forming, and welding to create finished components or assemblies ready for integration into your systems.

Our process for customization typically involves:

- Consultation: Detailed discussion of application requirements, environmental factors, and performance expectations.

- Design & Prototyping: Our engineers develop technical drawings and specifications, sometimes producing prototypes for client approval.

- Testing & Validation: Prototypes or initial production runs undergo rigorous testing to ensure they meet agreed-upon performance metrics and industry standards.

- Production & Delivery: Once validated, efficient production and on-time delivery are ensured, backed by our robust supply chain management.

This collaborative approach ensures that clients receive not just a product, but a precise solution engineered for their success. Our extensive experience in delivering bespoke Black Epoxy Coated Wire Mesh solutions across diverse industries underscores our expertise and trustworthiness as a partner.

Real-World Application Cases and Success Stories

The versatility and performance of Black Epoxy Coated Wire Mesh are best illustrated through its successful deployment in various demanding applications. Here are a few examples showcasing its efficacy:

Case Study 1: Coastal Water Treatment Plant Filters

A major municipal water treatment plant located on a coast faced constant issues with corrosion and premature failure of their traditional galvanized steel filter screens due to saline water and fluctuating pH levels. After switching to custom-designed Black Epoxy Coated Wire Mesh filters from our company, they reported a dramatic increase in filter lifespan, from an average of 3 years to over 12 years. The superior salt spray resistance of the epoxy coating (demonstrated by over 1500 hours in ASTM B117 tests) significantly reduced maintenance costs and operational downtime, leading to estimated savings of 25% annually on filter replacements and labor.

Case Study 2: Automotive Radiator Grille Inserts

A leading automotive manufacturer sought a durable, aesthetically pleasing, and corrosion-resistant material for their new line of vehicle radiator grilles. Traditional painted grilles chipped easily, leading to rust. Our Black Epoxy Coated Wire Mesh provided the perfect solution. Its impact resistance and exceptional stone chip resistance (tested to SAE J400 standards) ensured long-term visual integrity and protection for the radiator. The smooth, consistent black finish also aligned perfectly with their vehicle's design language, receiving positive feedback from end-users regarding durability and appearance.

Case Study 3: Industrial Oil & Gas Flare Stack Screens

In a challenging oil and gas environment, a client needed high-temperature and corrosion-resistant screens for flare stacks, exposed to extreme heat, UV radiation, and corrosive exhaust gases. While the base material was specialized stainless steel, the black epoxy coating was applied to provide additional UV stability and aesthetic uniformity across the facility. Even under these severe conditions, our specially formulated Black Epoxy Coated Wire Mesh demonstrated remarkable longevity and integrity, significantly outperforming previous solutions and contributing to operational safety and environmental compliance.

These cases underscore our commitment to delivering reliable, high-performance solutions that address complex industrial challenges, fostering long-term partnerships with our clients. Our customer feedback consistently highlights the superior quality and extended lifespan of our products, affirming our status as an authoritative and trustworthy supplier.

Ensuring Trust: Guarantees, Support, and Delivery

Building trust with our clients is at the core of our business philosophy. We achieve this through transparent processes, robust quality assurance, reliable logistics, and unwavering customer support. Our commitment to trustworthiness is reflected in several key aspects:

Quality Assurance & Warranty:

Every roll of Black Epoxy Coated Wire Mesh undergoes rigorous quality checks at multiple stages of production, from raw material inspection to final product packaging. We adhere strictly to international standards such as ISO 9001:2015. We offer a comprehensive product warranty against manufacturing defects and premature coating failure under specified conditions, typically ranging from 5 to 10 years, depending on the application and environment. Our confidence in our product's durability allows us to provide such robust guarantees.

Delivery & Lead Times:

We understand the importance of timely delivery for project timelines. Our standard lead time for Black Epoxy Coated Wire Mesh orders typically ranges from 2 to 4 weeks, depending on order volume and customization requirements. For urgent requests, expedited manufacturing and shipping options are available. We maintain robust logistics partnerships to ensure efficient and secure global delivery, tracking every shipment to its destination.

Customer Support & Technical Assistance:

Our dedicated customer support team is available to assist with all inquiries, from product selection to post-installation support. We provide comprehensive technical documentation, installation guides, and troubleshooting assistance. Our experienced engineers are also available for in-depth technical consultations, helping clients optimize their applications or resolve specific challenges. This commitment to continuous support ensures a seamless experience from inquiry to application, fostering long-term client relationships.

We believe that strong relationships are built on reliability and transparency. Our proactive communication and commitment to resolving any issues promptly reinforce our position as a trustworthy partner in the wire mesh industry. With a service history spanning over two decades, our longevity in the market speaks volumes about our reliability and commitment to customer satisfaction.

Frequently Asked Questions (FAQ) about Black Epoxy Coated Wire Mesh

Q1: What is the primary advantage of Black Epoxy Coated Wire Mesh over standard galvanized or stainless steel mesh?

A1: The primary advantage lies in its superior corrosion and chemical resistance, especially in harsh or acidic environments where even galvanized coatings might fail over time. The epoxy layer provides an additional robust barrier, extending the mesh's lifespan significantly. It also offers excellent electrical insulation and an appealing uniform black finish.

A2: Under normal outdoor conditions and with proper installation, Black Epoxy Coated Wire Mesh can have a service life exceeding 15-20 years. In highly corrosive industrial environments, its lifespan will still significantly outperform un-coated or standard coated alternatives.

Q3: Can this mesh be welded or cut after coating without compromising the epoxy layer?

A3: While the mesh can be cut, it's generally recommended to cut or fabricate the wire mesh prior to the epoxy coating process to ensure a complete, seamless coating and avoid exposing the raw edges to corrosion. If cutting is necessary post-coating, the exposed edges should be sealed with an appropriate epoxy paint or sealant to maintain corrosion resistance.

A4: Common base materials include low carbon steel wire, galvanized iron wire, and sometimes stainless steel wire (grades SS304, SS316) for applications requiring inherent high strength or specific chemical resistance before coating.

Q5: Is the black epoxy coating UV resistant?

A5: Yes, the epoxy formulations used for outdoor applications are designed to be highly UV resistant, ensuring the coating maintains its color, integrity, and protective properties even with prolonged exposure to sunlight.

A6: Our products comply with international quality management standards such as ISO 9001:2015. We also conduct performance tests according to relevant standards like ASTM B117 (Salt Spray Testing) for corrosion resistance and various industry-specific material and dimensional standards.

Q7: What is the typical range of mesh count and wire diameter available?

A7: We offer a wide range of mesh counts, typically from 4 mesh (coarse) up to 60 mesh (fine), and wire diameters ranging from 0.4mm to 2.5mm. Custom specifications are also available to meet unique project requirements.

Conclusion

Black Epoxy Coated Wire Mesh represents a significant advancement in material science, offering an optimal blend of durability, performance, and aesthetic appeal for a wide array of industrial and commercial applications. Its exceptional corrosion and chemical resistance, coupled with robust mechanical properties, ensure a prolonged service life and reduced maintenance, translating into considerable long-term savings for businesses.

As industry demands continue to evolve, seeking more resilient and sustainable solutions, the adoption of epoxy-coated wire mesh is poised for further growth. Our commitment to continuous innovation, rigorous quality control, and unparalleled customer support ensures that we remain at the forefront of this market, providing solutions that empower our clients to achieve their operational goals with confidence and efficiency.

For detailed technical specifications, customization options, or to discuss your specific project needs, please do not hesitate to contact our expert team. We are dedicated to providing the highest quality Black Epoxy Coated Wire Mesh solutions tailored to your exact requirements.

References and Further Reading