About ANPING YUANDONG METAL PRODUCT CO.,LTD.

As a leading manufacturer in China's security fencing industry, we specialize in high-performance Chain Link Fence solutions engineered for durability and security. With over 15 years of industry experience, our fences meet international quality standards.

Material: Low carbon steel wire with galvanized or PVC coating

Feature: Easy installation and maintenance

Applications: Perimeter security, sports fields, industrial areas, residential properties, and specialized filtration in rubber manufacturing

Market Growth and Industry Trends

The global Chain Link Fence market is projected to grow at a CAGR of 5.8% from 2023 to 2030 (Fence Market Analysis Report, 2023). This growth is primarily driven by increasing infrastructure investments and rising security concerns across multiple sectors.

"The versatility and cost-effectiveness of

Chain Link Fence solutions continue to make them the preferred choice for municipalities and industrial facilities alike" - International Fencing Association Journal.

Key industry developments shaping the Chain Link Fence sector include:

- Enhanced corrosion resistance through new hot-dip galvanizing techniques

- Eco-friendly manufacturing processes reducing carbon footprint by 30%

- Hybrid designs combining chain link with ornamental elements

- Smart fencing integration with surveillance systems

Technical Specifications and Standards

Proper Chain Link Fence specification requires understanding critical parameters:

| Parameter |

Standard Value |

Application |

ASTM Standard |

| Wire Diameter |

2.0mm - 4.5mm |

Light to heavy security |

F668-21 |

| Mesh Size |

25mm - 75mm |

Security level control |

A392-19 |

| Height |

0.5m - 4.0m |

Perimeter definition |

F567-19 |

| Galvanizing Weight |

80g/m² - 300g/m² |

Corrosion resistance |

A641/A641M-19 |

| Tensile Strength |

350 MPa - 600 MPa |

Impact resistance |

A824-17 |

Material Science and Manufacturing

Advanced material engineering plays a crucial role in Chain Link Fence performance:

"Recent innovations in zinc-aluminum alloy coatings have extended fence lifespan in coastal environments by 40%" - Materials Engineering Journal.

Our manufacturing process at ANPING YUANDONG METAL PRODUCT ensures precision in every aspect:

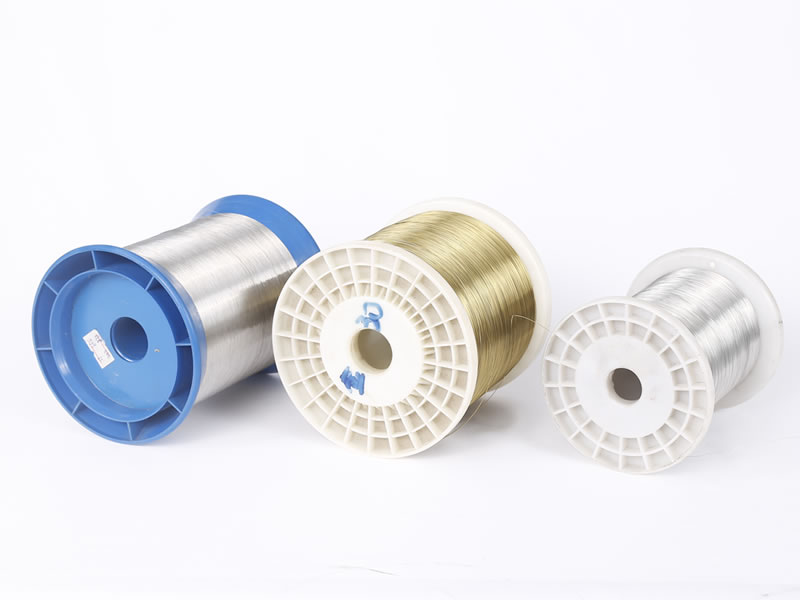

- Raw material selection: Certified low-carbon steel wire

- Wire drawing: Cold-worked to exact diameter requirements

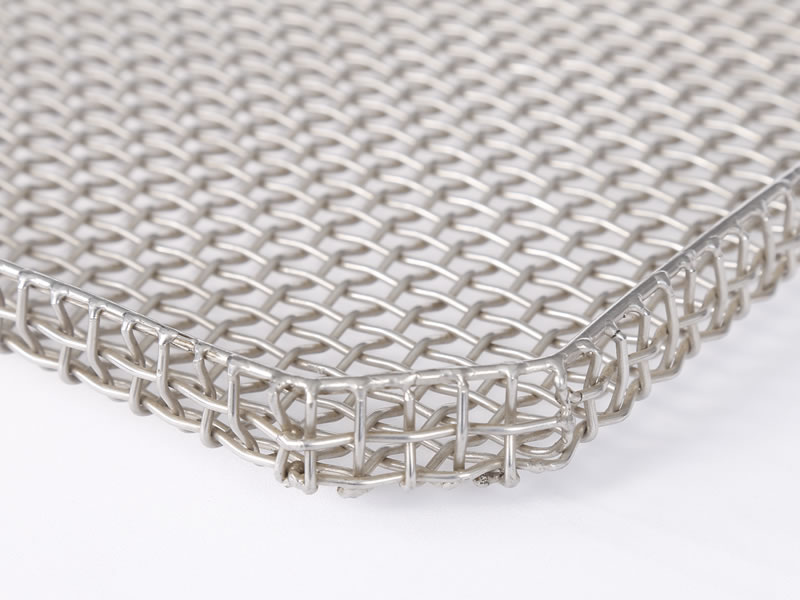

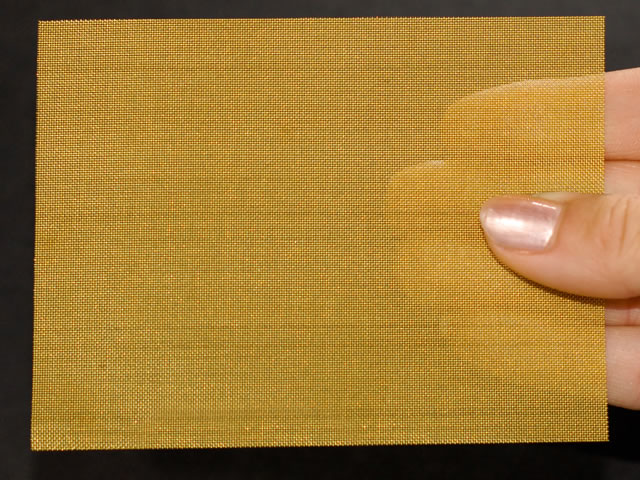

- Weaving: Computer-controlled machinery for uniform mesh geometry

- Coating: Dual protection system (galvanizing + PVC coating)

- Quality control: Load testing and salt spray certification

Application Scenarios and Use Cases

Versatility remains a hallmark feature of Chain Link Fence solutions:

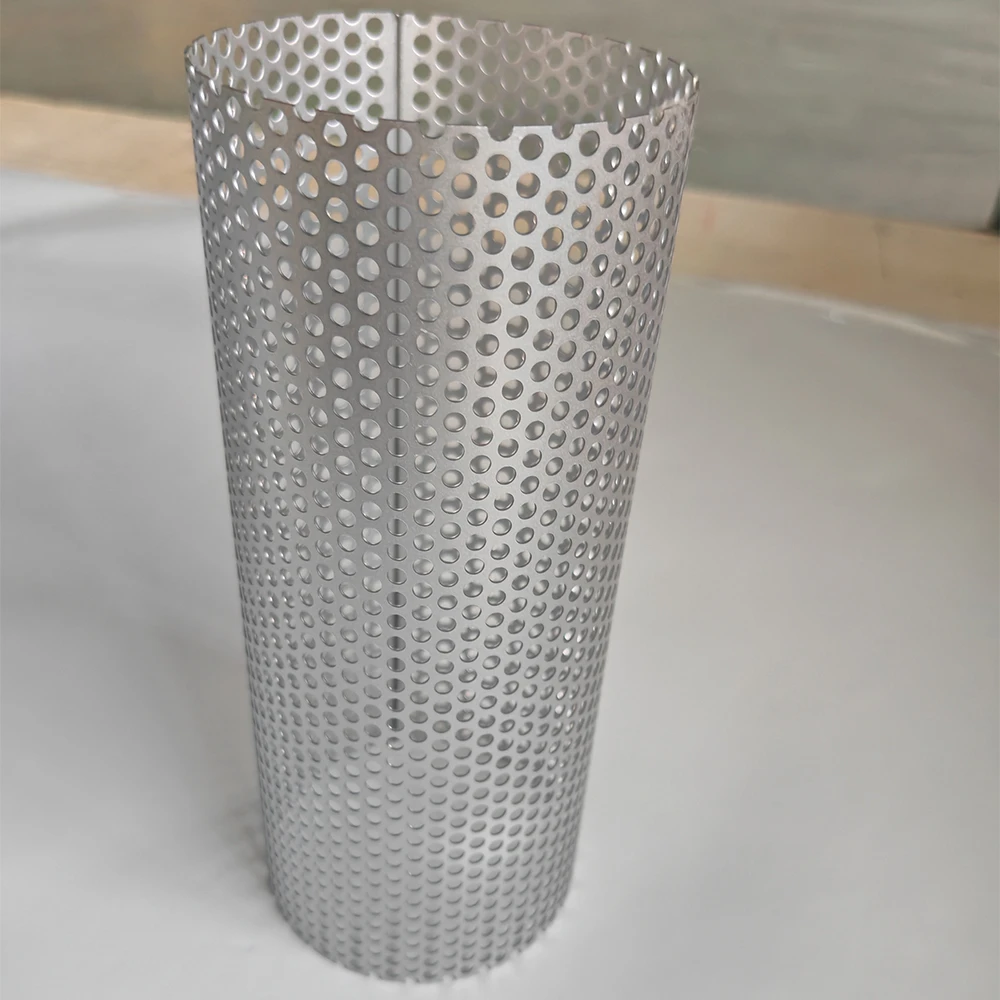

Industrial Security

High-tensile Chain Link Fence protects critical infrastructure with 4.0mm gauge wire and reinforced framework meeting MILSPEC standards.

Public Facilities

Schools and parks benefit from vandal-resistant designs with anti-climb features that provide safety without visual obstruction.

Specialized Filtration

Our precision-mesh Chain Link Fence serves rubber and chemical industries with mesh accuracy within ±0.5mm tolerance.

Residential Applications

Decorative vinyl-coated options blend security with aesthetics for residential properties.

Professional Installation Guide

Correct installation methods ensure maximum performance of Chain Link Fence systems:

"Industry research indicates proper tensioning increases fence lifespan by 60% compared to improperly installed systems" - Construction Materials Quarterly

Key installation considerations include:

- Post spacing optimization based on terrain and fence height

- Proper concrete footing depth (30% of post height minimum)

- Tension wire placement methodology

- Corner reinforcement techniques

- Special considerations for sloped terrain

Maintenance and Longevity

With proper maintenance, premium Chain Link Fence systems offer 25+ years of service:

"Galvanized chain link with periodic maintenance delivers the lowest lifecycle cost of any security fencing solution" - Facility Management Review

Maintenance protocols from the International Fencing Association:

| Maintenance Interval |

Recommended Procedures |

Equipment Required |

| Quarterly |

Visual inspection for damage

Hardware tightening |

Binoculars

Torque wrench |

| Annually |

Structural integrity assessment

Coating inspection |

Thickness gauge

Tension meter |

| 5 Years |

Comprehensive corrosion assessment

Post stability check |

Ultrasonic tester

Concrete scanner |

Professional FAQ: Chain Link Fence Specifications

Q: What gauge thickness is recommended for high-security applications?

A: Security-grade installations require minimum 11-gauge wire (3.05mm diameter) with framework posts conforming to ASTM F1043 standards for impact resistance.

Q: How does zinc coating weight affect fence durability?

A: Galvanizing class correlates directly with lifespan: Class I (G90) offers 350g/m² protection suitable for 15-20 years in normal environments, while Class III (G210) with 750g/m² provides 30+ years in corrosive environments.

Q: What mesh size provides optimal visibility-to-security balance?

A: The industry-standard 50mm diamond pattern (2-inch mesh) offers the best combination of transparency and barrier effectiveness, deterring climbing attempts while maintaining sightlines.

Q: Which framework specification prevents post-sagging?

A: Terminal posts should have minimum 2.5-inch diameter for fences up to 6ft, increasing to 3.5-inch diameter for 8ft installations per ASTM F567 specifications. Concrete footings should extend 30% of post height.

Q: How does tensile strength affect impact resistance?

A: Minimum 38,000 PSI tensile strength provides adequate resistance against human impact. Security applications require 65,000 PSI minimum for vehicular impact resistance.

Q: What's the standard coating adhesion test protocol?

A: PVC coatings should withstand 500+ hours salt spray testing (ASTM B117) without base metal corrosion. Adhesion testing per ASTM D3359 requires classification B or better.

Q: How does wire diameter affect mesh strength?

A: Strength increases exponentially with wire diameter - 9-gauge (3.76mm) offers approximately 150% higher break strength than 11-gauge (3.05mm) at equivalent mesh sizes.

Certifications and Compliance Standards

Our Chain Link Fence products meet rigorous international certifications:

- ASTM F668: Standard Specification for Polymeric Chain Link Fencing

- ISO 1461: Hot Dip Galvanized Coatings Protection

- BS 1722: Specification for Fences

- MIL-F-19171D: Military Specification for Fence Materials

- NCCA 631: Protective Coating Standards

"Third-party certification has been shown to reduce installation failures by 78% across major projects" - Building Safety Journal

Environmental Impact Considerations

Modern Chain Link Fence manufacturing incorporates sustainable practices:

- 95%+ material recyclability at end-of-life

- Closed-loop water systems in galvanizing processes

- Low-VOC coating technologies compliant with EPA standards

- Energy-efficient electric galvanizing alternatives

"Lifecycle analysis shows chain link fencing produces 35% less carbon emissions than concrete security walls" - Sustainable Infrastructure Report

"Advancements in polymer coatings continue to expand applications for chain link fencing" - Materials Science Today

"Proper specification remains critical for security installations - industry standards have reduced failure rates by 62% since 2010" - Security Infrastructure Magazine

Source: International Fencing Standards Association (www.fencingstandards.org/chain-link-specs)

Source: Global Construction Materials Report (www.conmatglobal.com/fencing-trends)

Source: Materials Engineering Journal (www.mej.org/volume48/corrosion-resistance)