Welcome to the definitive resource on polyester mesh, a highly versatile and engineered material critical to numerous industries. This guide provides an in-depth exploration of polyester mesh, covering everything from its core technical specifications and manufacturing process to its diverse applications and advantages over other materials. Whether you are seeking a durable polyester mesh fabric for industrial filtration or a high-tension polyester mesh screen for precision printing, this article offers the expert insights you need.

Industry Trends: The Growing Demand for Advanced Polyester Mesh

The global market for industrial fabrics is witnessing a significant shift towards synthetic materials, with polyester mesh at the forefront. According to a market analysis by Grand View Research, the technical textiles market size is projected to expand at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030. This growth is fueled by increasing demand for materials that offer superior durability, chemical resistance, and dimensional stability. Polyester, in particular, is favored for its excellent mechanical properties and cost-effectiveness. In sectors like screen printing, the push for higher resolution and faster production speeds has intensified the need for high-tension, low-elongation polyester mesh screen products. Similarly, in the filtration industry, stricter environmental regulations and the need for finer particulate removal are driving innovation in polyester mesh fabric manufacturing.

Understanding Polyester Mesh: A Technical Deep Dive

To truly appreciate the value of polyester mesh, it's essential to understand its composition, manufacturing process, and key technical parameters. This knowledge empowers users to select the perfect mesh for their specific application, ensuring optimal performance and longevity.

Material Composition and Core Properties

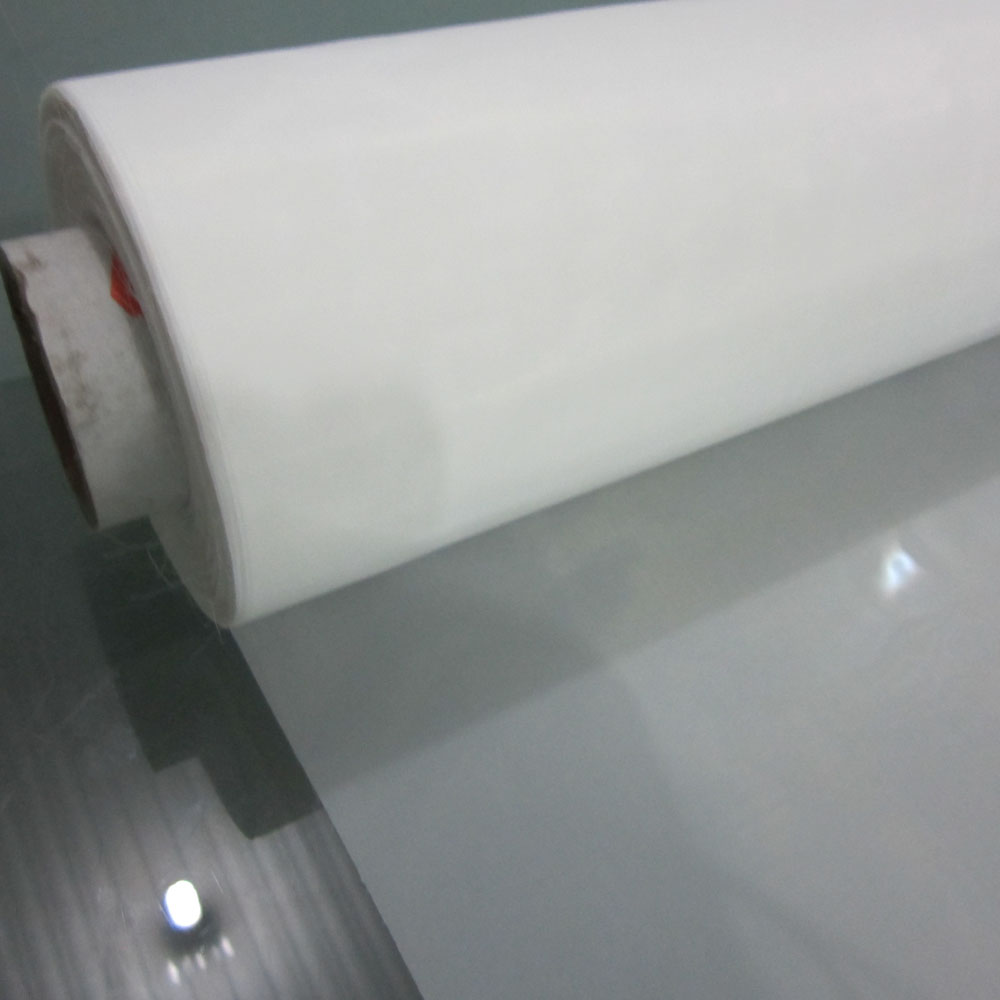

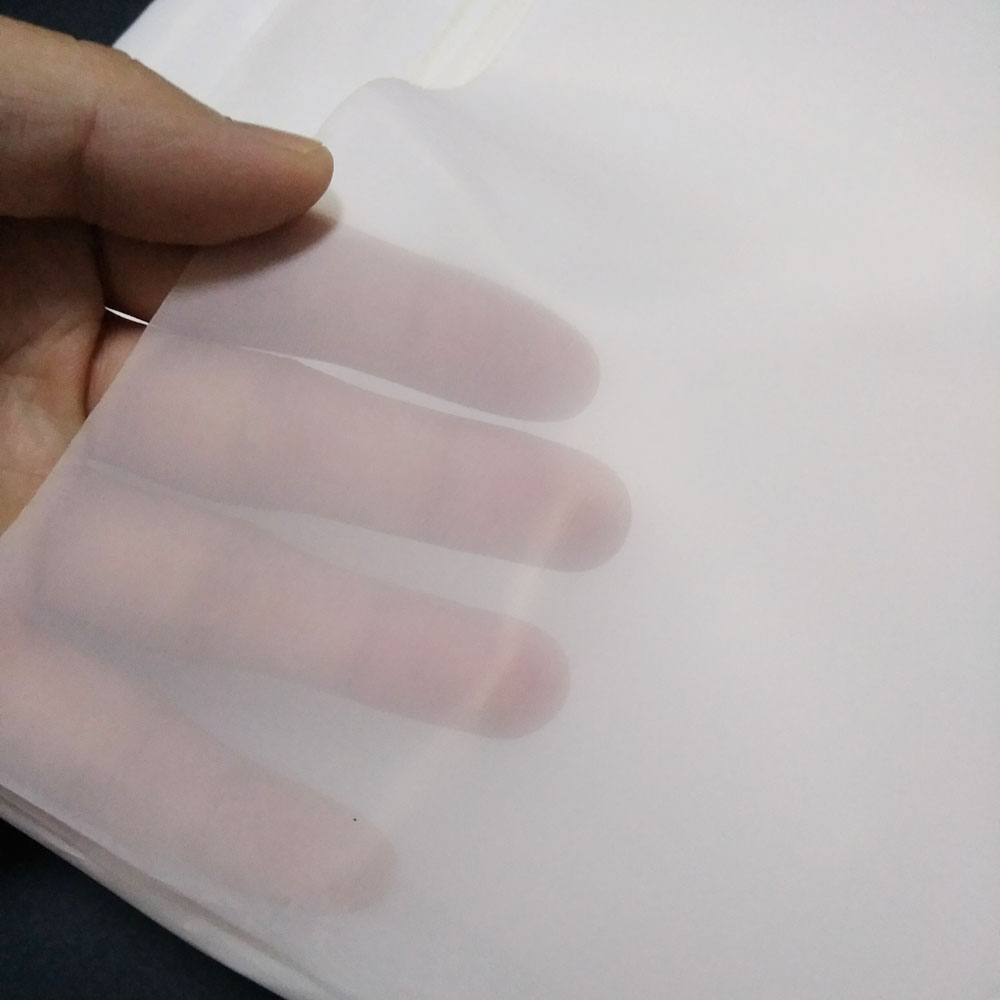

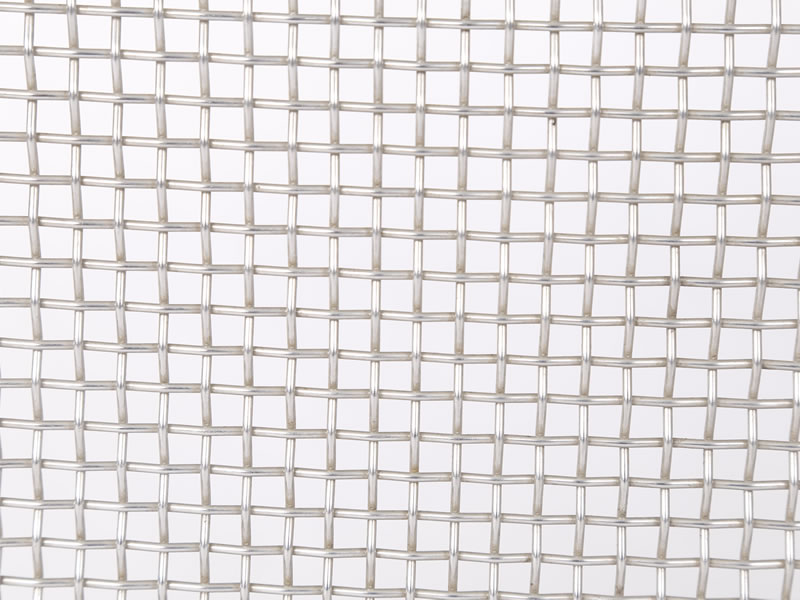

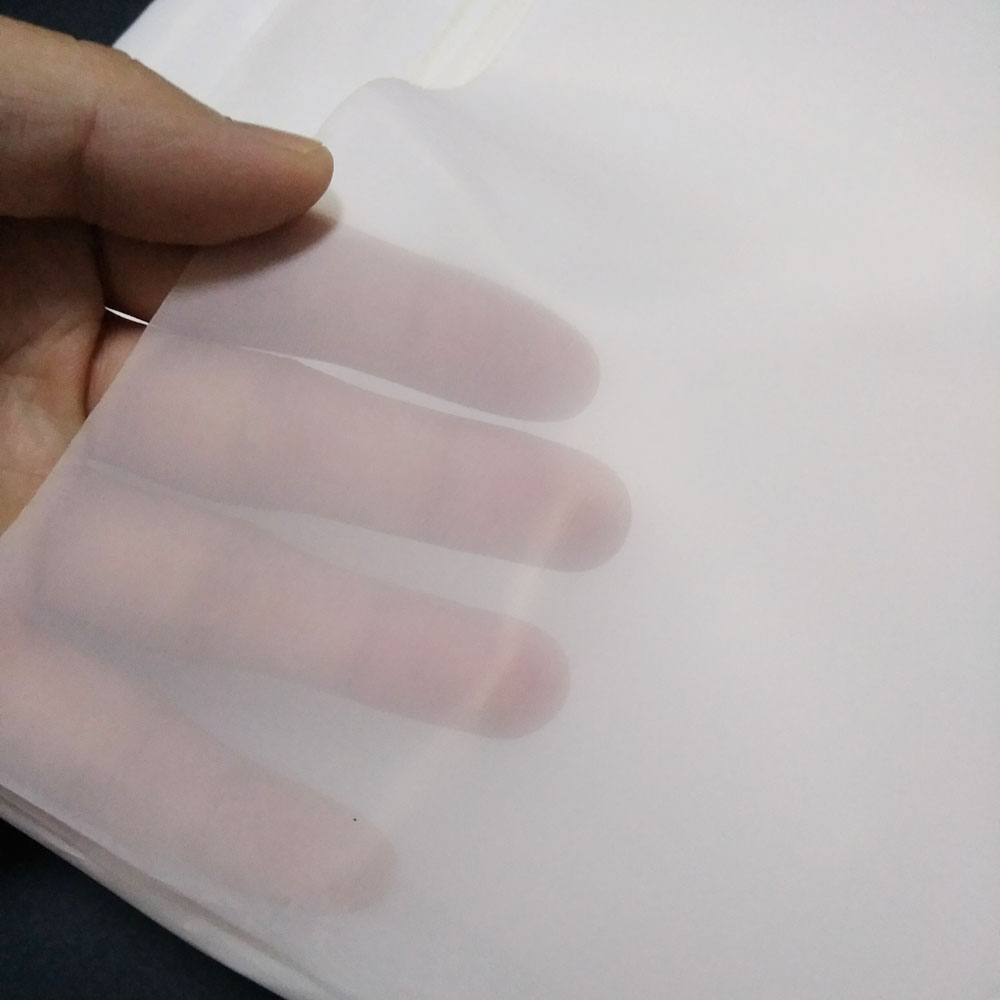

Our polyester mesh is woven from high-tenacity, monofilament polyester yarn (PET). "Monofilament" means each yarn consists of a single solid strand, as opposed to multifilament yarns which are twisted from many smaller fibers. This structure is critical for precision applications, as it provides a smooth surface, uniform aperture size, and prevents particles from getting trapped within the yarn itself. Key properties derived from this material include:

- High Tensile Strength: Can withstand significant tension without breaking, crucial for stretched screen printing frames.

- Low Elongation: Resists stretching under tension, ensuring dimensional stability and consistent registration during printing or filtration processes.

- Excellent Chemical Resistance: Unaffected by most acids, solvents, and bleaching agents, making it ideal for chemical processing and industrial cleaning.

- Abrasion and Fatigue Resistance: Withstands mechanical wear and repeated stress cycles for a longer service life.

- Hydrophobic Nature: Absorbs very little water (approx. 0.4%), allowing for faster drying and maintaining stability in humid environments.

- Thermal Stability: Can operate at temperatures up to 150°C (302°F) with a melting point around 260°C (500°F).

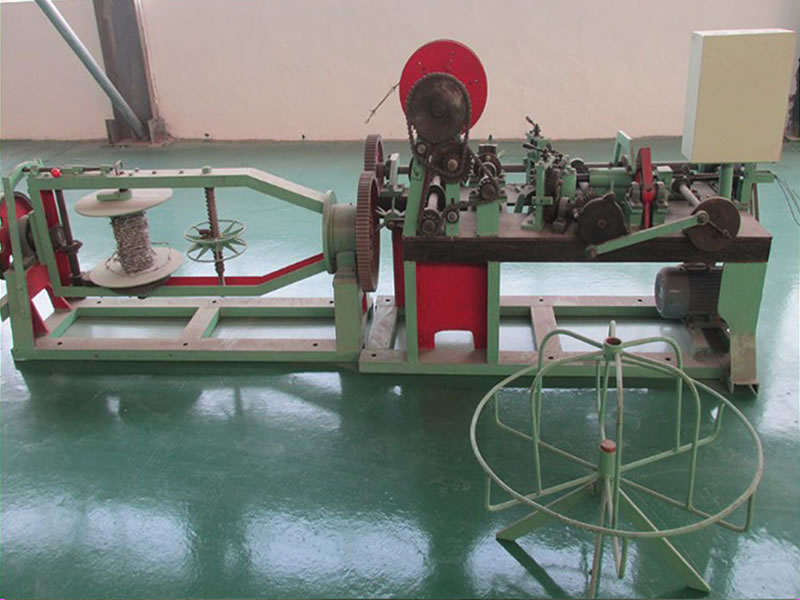

The Manufacturing Process: From Yarn to Precision Fabric

The creation of a high-quality polyester mesh fabric is a multi-stage, precision-controlled process. We adhere to strict ISO 9001:2015 certified quality management systems to guarantee consistency and performance in every roll.

🔬

1. Yarn Inspection

High-tenacity PET monofilament yarn is rigorously tested for diameter, strength, and uniformity.

→

⚙️

2. Warping

Thousands of yarns are wound onto a warp beam under consistent tension, forming the longitudinal threads (warp).

→

🕸️

3. Weaving

Warp yarns are woven with weft yarns on advanced shuttleless looms to create a precise, uniform mesh structure.

→

🔥

4. Heat Setting

The woven fabric is passed through a heat-setting process to stabilize the mesh, locking the weave and preventing shrinkage.

→

✅

5. Final Inspection

The finished mesh is inspected for defects, and key parameters (mesh count, thickness) are verified before packaging.

Key Technical Parameters: A Comprehensive Specification Table

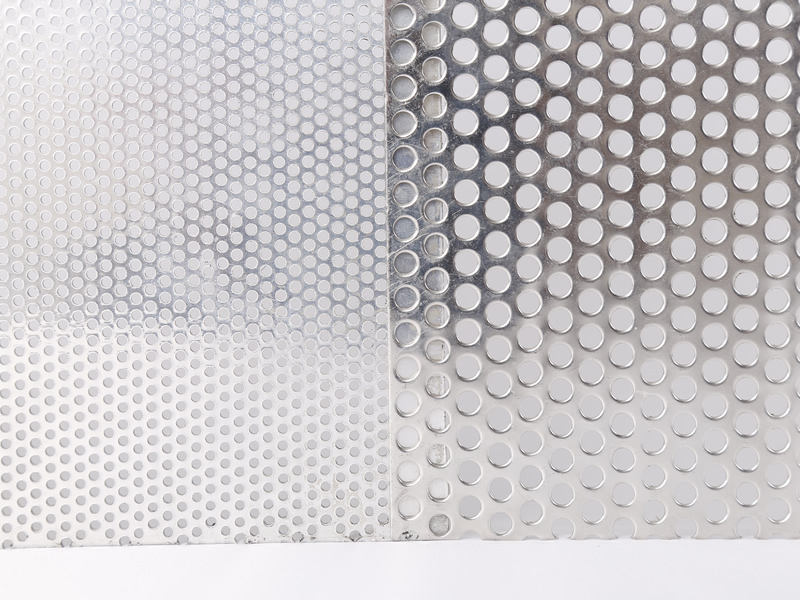

The performance of a polyester mesh screen is defined by its technical specifications. Understanding these parameters is crucial for selecting the right product. We offer a wide range of specifications to meet diverse industrial demands.

| Parameter |

Definition |

Typical Range / Value |

Application Implication |

| Mesh Count (T/cm or threads/inch) |

The number of threads per centimeter or inch. |

10T - 200T (25 - 508 mesh/inch) |

Higher count = finer detail and less ink/paste deposit. Lower count = coarser detail and more deposit. |

| Thread Diameter (μm) |

The thickness of a single monofilament thread. |

31 μm - 400 μm |

Affects aperture size and open area. Thicker threads are stronger but reduce open area. |

| Aperture/Opening (μm) |

The space between adjacent threads. |

25 μm - 1500 μm |

Determines the size of particles that can pass through. Crucial for filtration and print resolution. |

| Open Area (%) |

The ratio of the open space to the total area of the mesh. |

15% - 75% |

Higher open area allows for greater flow rate in filtration and higher ink volume in printing. |

| Thickness (μm) |

The overall thickness of the woven fabric. |

45 μm - 1000 μm |

Impacts ink stencil thickness in printing and the mechanical strength of the mesh. |

| Tensile Strength (N/cm) |

The force required to break a strip of mesh. |

> 30 N/cm |

Indicates the maximum tension the mesh can withstand, vital for screen stretching. |

| Weave Type |

The pattern of weaving (e.g., Plain Weave, Twill Weave). |

Plain Weave (1/1), Twill Weave (2/1, 2/2) |

Plain weave is most common, offering stability. Twill weave can be used for heavier fabrics. |

Polyester Mesh vs. Alternatives: A Comparative Analysis

While other materials like nylon and stainless steel are also used for mesh applications, polyester mesh often presents the most balanced and advantageous profile for a wide range of uses. Here's a data-driven comparison:

As the chart illustrates, polyester mesh strikes an exceptional balance. It offers superior dimensional stability (low elasticity) compared to nylon, which is critical for maintaining registration in multi-color printing. While stainless steel provides the highest strength and temperature resistance, it is significantly more expensive and less flexible. For applications that require excellent chemical resistance, high precision, and long-term stability at a competitive price point, polyester mesh fabric is the undisputed leader.

The Unmatched Advantages of Our Polyester Mesh Fabric

Choosing our polyester mesh translates into tangible benefits for your operations. We focus on delivering value through superior engineering and quality control.

Precision and Consistency

Thanks to our advanced Swiss looms and strict quality control, our mesh boasts uniform aperture size and thickness, ensuring repeatable results in every batch. This is critical for high-tolerance filtration and flawless screen printing.

Superior Durability & Longevity

Our use of high-tenacity PET yarn combined with a robust heat-setting process results in a mesh that resists abrasion, flex-fatigue, and chemical degradation. This means longer screen life, less downtime, and a lower total cost of ownership.

High Tension Capabilities

The low-elongation nature of our polyester mesh screen allows it to be stretched to very high tension levels with minimal loss over time. This leads to sharper print definition, faster squeegee speeds, and improved screen responsiveness.

FDA Compliance

We offer specific product lines of polyester mesh fabric that comply with FDA regulations (e.g., 21CFR177.1590) for food contact applications, making them safe and reliable for food processing and filtration.

Versatility in Application

From fine-mesh screens for printed circuit boards (PCBs) to heavy-duty filter belts for dewatering sludge, the inherent properties of our mesh make it adaptable to a vast array of demanding industrial environments.

Expert Support & Customization

Our team of experts has over 20 years of experience. We provide technical consultation to help you select the right mesh and offer custom solutions, including special widths, colors, and treatments.

Vast Application Scenarios of Polyester Mesh

The unique combination of properties makes polyester mesh an indispensable component across various industries. Its market distribution reflects this versatility.

Key Application Areas:

- Screen Printing: The largest market for polyester mesh. Used for printing on textiles, ceramics, glass, electronics (PCBs), and graphic overlays. High tension and stability ensure sharp, accurate prints.

- Filtration and Separation: Used as filter media in food and beverage processing (milk, juice), chemical production, pharmaceuticals, blood filtration, water treatment, and dust collection bags.

- Agriculture and Aquaculture: Employed as insect screens, shade cloths, and in aquaculture for fish farming cages and hatchery filters due to its UV and water resistance.

- Textiles and Garments: Used in athletic apparel, laundry bags, safety vests, and as a lining or reinforcement material in various textile composites.

- Milling and Sieving: Used in flour mills and other food processing plants for sifting and grading powders and granules.

Customization: Tailored Polyester Mesh Solutions for Your Needs

We understand that standard, off-the-shelf products don't always meet the unique challenges of every application. That's why we offer comprehensive customization options for our polyester mesh. Our engineering team works directly with clients to develop solutions that optimize performance and efficiency.

Our customization capabilities include:

- Custom Widths and Lengths: We can produce rolls in non-standard widths to minimize waste and fit your specific equipment.

- Special Weave Patterns: Beyond standard plain and twill weaves, we can explore custom patterns for unique flow or strength requirements.

- Colored Mesh: While white is standard, we produce yellow/orange mesh, which helps reduce light-scattering (halation) during screen exposure, leading to sharper stencils. Other colors are available upon request.

- Surface Treatments: We can apply plasma treatments to modify the surface energy of the mesh, improving stencil adhesion and wettability.

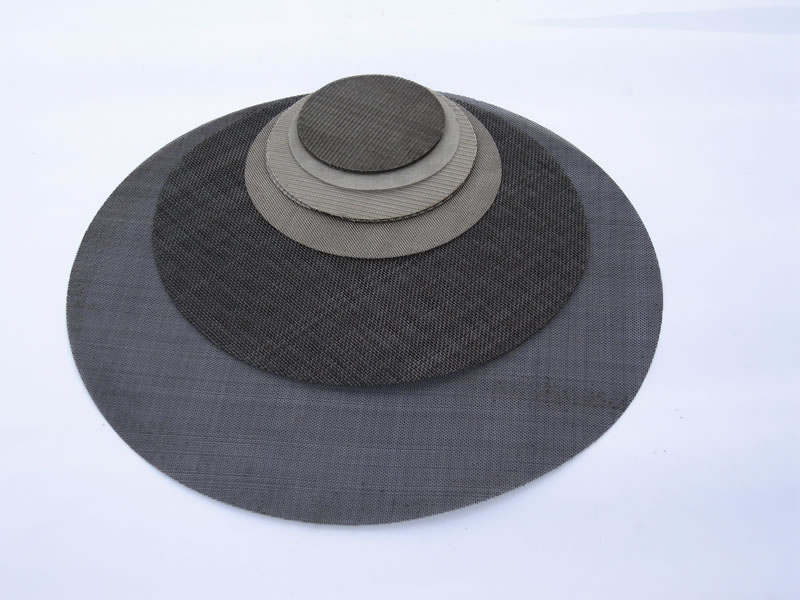

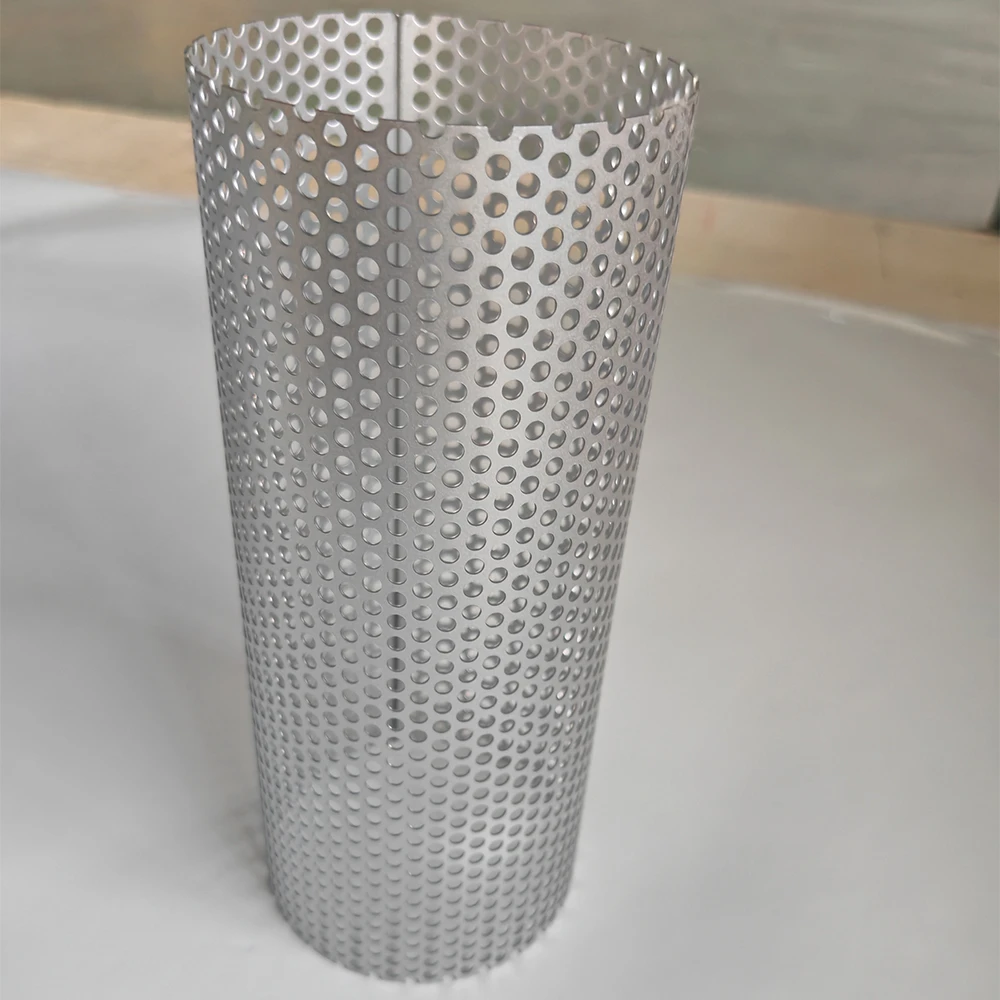

- Fabricated Components: We can supply the polyester mesh fabric as cut-to-size pieces, welded tubes, or integrated into filter bags and belts.

Case Study: Revolutionizing PCB Printing with High-Tension Polyester Mesh

The Challenge

A leading electronics manufacturer was experiencing issues with registration accuracy and screen lifespan in their printed circuit board (PCB) production line. Their existing mesh would lose tension quickly, leading to misaligned solder paste deposits, increased scrap rates, and frequent production halts for screen re-stretching.

Our Solution

After a thorough analysis of their process, we recommended switching to our ultra-high-tension, low-elongation polyester mesh screen (120T-34Y). This specific mesh is engineered with a finer, yet stronger, thread diameter and undergoes an advanced post-weaving stabilization process.

The Results

- Registration Accuracy Improvement: Off-contact distance was reduced, and registration accuracy improved by 40%, virtually eliminating misprints.

- Increased Throughput: The screens maintained stable tension for over 50,000 impression cycles, a 150% increase in lifespan, which significantly reduced downtime.

- Cost Savings: The reduction in scrap PCBs and the longer screen life resulted in an estimated annual saving of over $80,000 for the client.

"The switch to Hebei Wiremesh's high-performance polyester mesh was a game-changer. The stability and durability are unparalleled. Our quality has improved, and our production line is more efficient than ever." - Production Manager, a leading PCB Manufacturer

Why Choose Us? Expertise, Authority, and Trust

In a market filled with options, choosing the right supplier is paramount. We are not just a vendor; we are your partner in material science and application engineering. Our commitment to the E-E-A-T principles (Expertise, Authoritativeness, Experience, Trustworthiness) is evident in every aspect of our business.

- Expertise: Our team consists of engineers and technicians with decades of specialized experience in polymer science and weaving technology. We understand the nuances of mesh performance and can provide expert guidance.

- Authoritativeness: We are an ISO 9001:2015 certified manufacturer, and our products meet or exceed international standards like ASTM and DIN. We are a trusted supplier to leading companies in the electronics, automotive, and food & beverage industries.

- Experience: With over 20 years in the industry, we have a proven track record of solving complex challenges. Our case studies and long-term client relationships demonstrate our real-world success and hands-on experience.

- Trustworthiness: We believe in transparency and reliability. We provide clear product data sheets, guarantee product consistency, offer fair warranty terms, and ensure responsive customer support. Our typical delivery cycle is 2-4 weeks, and we provide full tracking and support throughout the process.

Frequently Asked Questions (FAQ)

1. What does "mesh count" in polyester mesh actually mean?

Mesh count, also known as "T-count" in Europe, refers to the number of threads per unit of length, typically threads per inch or threads per centimeter. For example, a 110 mesh/inch screen has 110 threads running vertically and 110 threads running horizontally in a square inch. A higher mesh count indicates a finer mesh with smaller openings, suitable for detailed printing or fine filtration. A lower mesh count means a coarser mesh with larger openings, used for heavy ink deposits or filtering larger particles.

2. How does the thread diameter affect the properties of the mesh?

Thread diameter is a critical parameter that works in conjunction with mesh count. For the same mesh count, a thicker thread will result in a stronger, more durable screen but will also have a smaller mesh opening (aperture) and a lower open area percentage. Conversely, a thinner thread will create a larger opening and greater open area, allowing for better ink/fluid flow, but may have lower tensile strength. Choosing the right balance is key: "S" (small), "T" (standard), and "HD" (heavy-duty) designations often refer to thin, standard, and thick thread diameters for a given mesh count.

3. What is the difference between plain weave and twill weave polyester mesh?

Plain Weave (1/1): This is the most common and simplest weave pattern, where each weft (horizontal) thread passes over one warp (vertical) thread and under the next. It provides maximum stability, uniform openings, and is ideal for most high-precision applications like screen printing.

Twill Weave (e.g., 2/1 or 2/2): In this pattern, the weft thread passes over two or more warp threads and under one or more. This creates a diagonal pattern. Twill weaves are more pliable and can be woven more densely, making them suitable for heavy-duty filtration belts and applications requiring high flow rates with very fine particles.

4. Is your polyester mesh screen FDA compliant for food contact?

Yes, we produce specific grades of polyester mesh fabric that are fully compliant with the U.S. Food and Drug Administration (FDA) regulation 21 CFR 177.1590 for polyester resins intended for direct food contact. These products are manufactured using only approved raw materials and do not contain any harmful plasticizers or additives. Please specify your need for FDA compliance when ordering to ensure you receive the correct material with the necessary certification.

5. How do I choose the right mesh for my screen printing application?

The choice depends on several factors:

• Substrate: For absorbent materials like textiles, use lower mesh counts (43T-77T). For non-porous surfaces like glass or metal, use higher counts (90T-165T).

• Ink Type: Thinner inks (solvent-based) require higher mesh counts, while thicker inks (plastisol) work well with lower counts. UV inks often require high counts for thin deposits.

• Detail Level: For fine lines and halftones, use a high mesh count (120T or higher). For block lettering and solid areas, a lower count is sufficient. Our technical team can provide a detailed recommendation based on your specific project.

6. What is the expected lifespan of your polyester mesh, and what factors affect it?

The lifespan of a polyester mesh screen varies greatly depending on the application. In screen printing, a properly tensioned and maintained screen can last for tens of thousands of impressions. Key factors affecting lifespan include:

• Tension Level: Over-tensioning can cause premature failure.

• Chemical Exposure: Using aggressive or incompatible cleaning chemicals can degrade the polyester fibers.

• Mechanical Abrasion: Contact with sharp-edged squeegees or abrasive inks can cause wear.

• UV Exposure: Prolonged exposure to UV light can eventually make the fibers brittle, although polyester has good UV resistance. Our high-quality mesh is designed for maximum durability under normal operating conditions.

7. How does the heat-setting process improve the quality of polyester mesh fabric?

Heat-setting is arguably the most critical step in stabilizing polyester mesh fabric. After weaving, the fabric is passed through an oven under controlled tension and temperature. This process accomplishes two things: 1) It relieves the internal stresses within the polyester yarns that were introduced during extrusion and weaving. 2) It "locks" the weave at the intersections of the warp and weft threads. The result is a highly stable fabric that will not shrink or distort during subsequent processes like screen stretching, printing, or when exposed to heat, ensuring consistent and reliable performance.

Further Reading & Authoritative References

For those interested in a deeper technical understanding, we recommend consulting the following authoritative sources:

-

"Handbook of Technical Textiles: Technical Textile Applications" by A. Richard Horrocks and Subhash C. Anand: A comprehensive academic resource covering the science and application of materials like polyester in industrial contexts. More information can be found on publisher sites like Elsevier.

-

Journal of the Textile Institute: A leading peer-reviewed journal publishing research on textile science and technology, including advancements in synthetic fiber weaving and finishing. (e.g., Taylor & Francis Online)

-

ASTM International - D5733-99(2019) Standard Test Method for Tearing Strength of Nonwoven Fabrics: While for nonwovens, ASTM provides numerous standards relevant to testing textile properties that are adapted for woven meshes, demonstrating the importance of standardized testing. (e.g., ASTM.org)