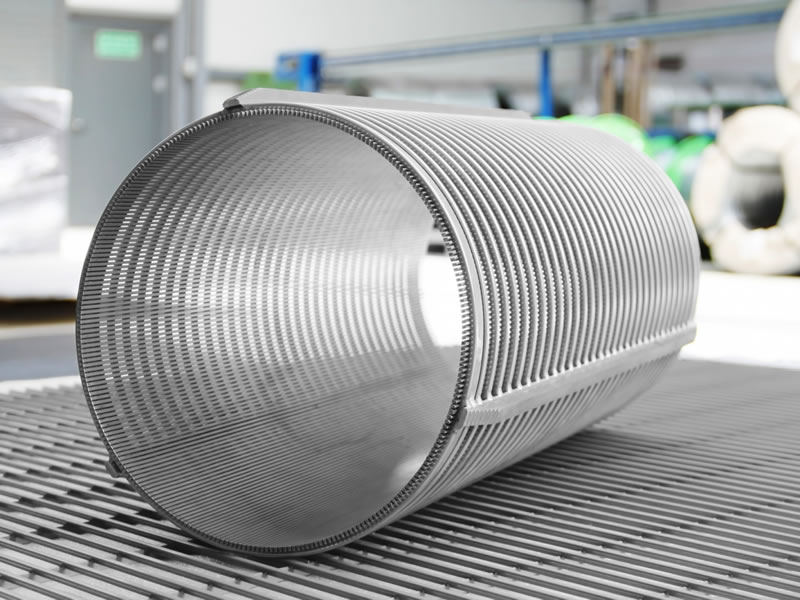

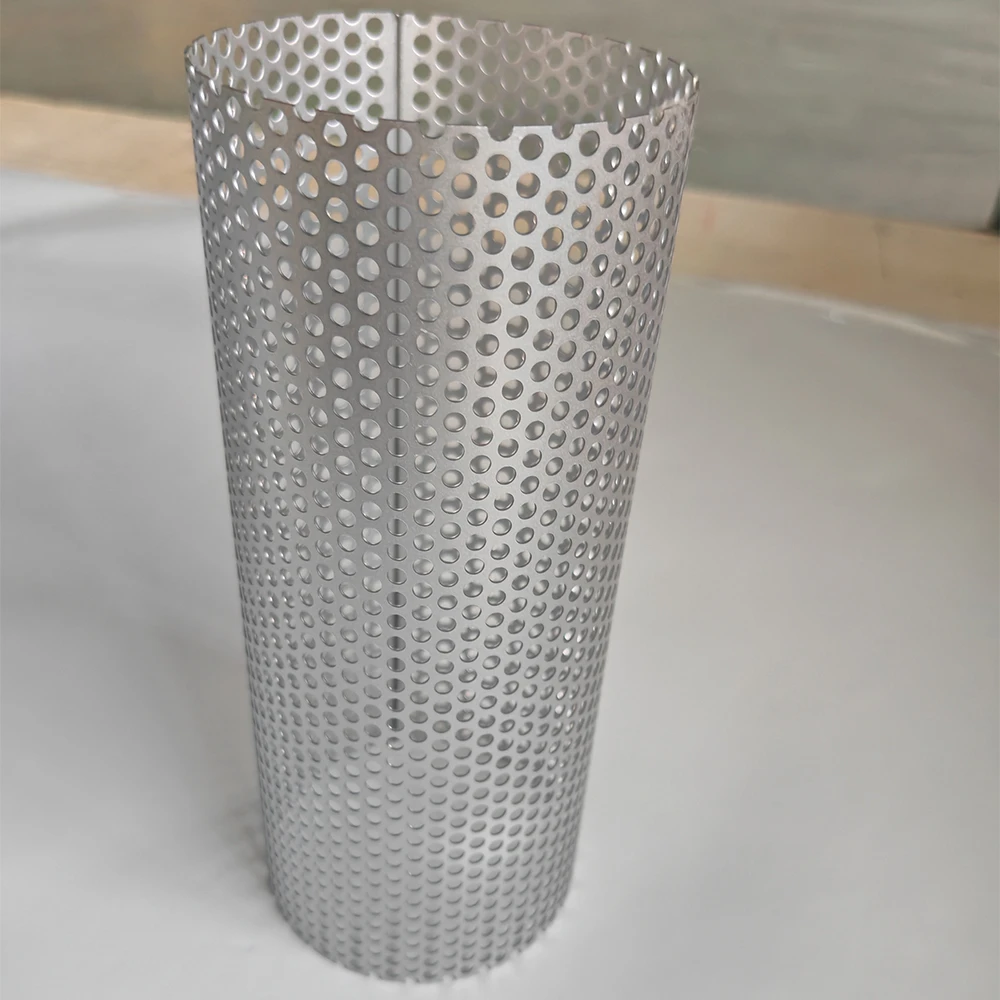

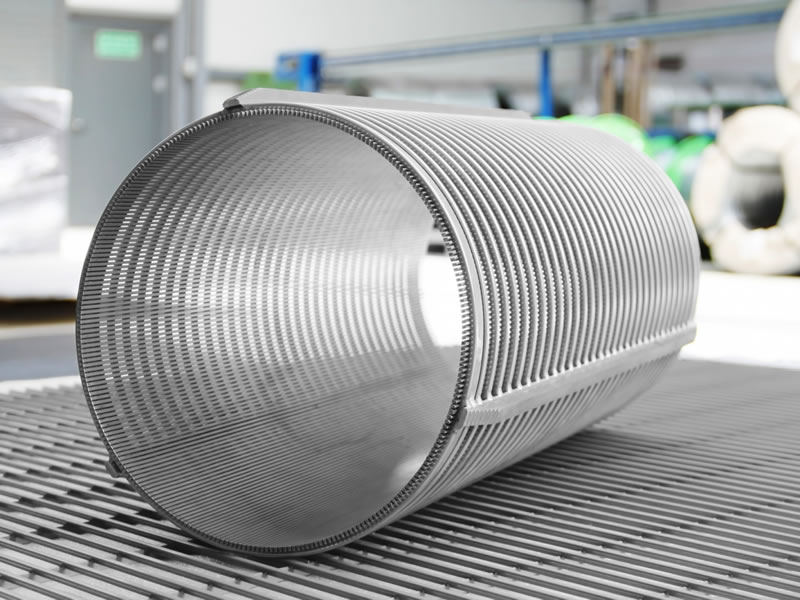

In the realm of industrial filtration, separation, and screening, the demand for highly efficient, durable, and reliable solutions is paramount. Industries ranging from petrochemicals and mining to water treatment and food processing constantly seek advanced components capable of withstanding harsh operating conditions while delivering superior performance. Among these critical components, wedge wire screen for sale stands out as a leading-edge technology, offering unparalleled advantages over traditional screening methods. Its unique construction, characterized by precisely shaped V-profile wires welded onto support rods, creates a non-clogging surface that ensures efficient liquid-solid separation, classification, and dewatering. This intricate design not only optimizes flow rates and minimizes maintenance requirements but also significantly extends the operational lifespan of industrial systems. The versatility of wedge wire screens allows them to be custom-engineered into various forms, including flat panels, cylindrical baskets, sieve bends, and well screens, catering to a diverse array of application-specific needs. As a critical component in many industrial processes, understanding the inherent benefits, technical specifications, manufacturing intricacies, and diverse applications of wedge wire screens is crucial for procurement managers, engineers, and technical specifiers looking to enhance operational efficiency, reduce downtime, and improve overall product quality. This comprehensive guide delves deep into the world of wedge wire technology, providing a detailed overview that encompasses everything from material selection and fabrication processes to real-world application scenarios and crucial considerations for selecting a reputable manufacturer. We will explore how these screens contribute to sustainable industrial practices by optimizing resource utilization and minimizing waste generation, ultimately presenting a compelling case for their integration into modern industrial infrastructure. The information presented here is meticulously curated to assist B2B decision-makers in making informed choices that align with their operational objectives and long-term strategic goals, emphasizing the robust capabilities and economic advantages of investing in high-quality wedge wire solutions for various industrial filtration and separation challenges.

Industry Trends and Market Dynamics for Wedge Wire Screens

The global market for `wedge wire screen` and related filtration products is experiencing robust growth, driven by escalating demands across key industrial sectors and increasing regulatory pressures concerning environmental protection and water resource management. Several significant trends are shaping this market. Firstly, the burgeoning water and wastewater treatment sector is a primary catalyst, as the need for effective filtration, dewatering, and solid-liquid separation becomes more pronounced with growing populations and industrialization. Wedge wire screens, with their high open area and non-clogging properties, are ideally suited for processes like municipal wastewater clarification, industrial effluent treatment, and potable water filtration, making them a sought-after solution for municipalities and private water utility companies. Secondly, the oil and gas industry, despite its cyclical nature, continues to be a substantial consumer, particularly for well screens in exploration and production, where precise sand control and efficient fluid extraction are critical. The durability and corrosion resistance of stainless steel `wedge wire screen` components make them indispensable for downhole applications and offshore platforms facing challenging conditions. Thirdly, the mining and minerals processing industry is witnessing increased adoption of `wedge wire screen panel` and other configurations for mineral sizing, slurry dewatering, and aggregate classification, driven by the need to optimize recovery rates and improve product purity. Technological advancements in manufacturing, such as precision welding techniques and the development of new alloys, are also contributing to enhanced product performance and broader application possibilities. The emphasis on sustainability and circular economy principles is pushing industries to adopt more efficient and durable filtration solutions that reduce waste and extend equipment lifespans, aligning perfectly with the inherent characteristics of wedge wire technology. Furthermore, the rise of custom fabrication services allows for highly specialized `wedge wire screen for sale` solutions tailored to unique operational parameters, driving innovation and market expansion. This customization capability is crucial for addressing niche applications in pharmaceuticals, food and beverage processing, and pulp and paper, where strict hygiene and material compatibility standards must be met. The market is also seeing a shift towards higher-grade materials like Duplex stainless steels and superalloys for extreme environments, reflecting the industry's commitment to durability and long-term performance.

Detailed Manufacturing Process of Wedge Wire Screens

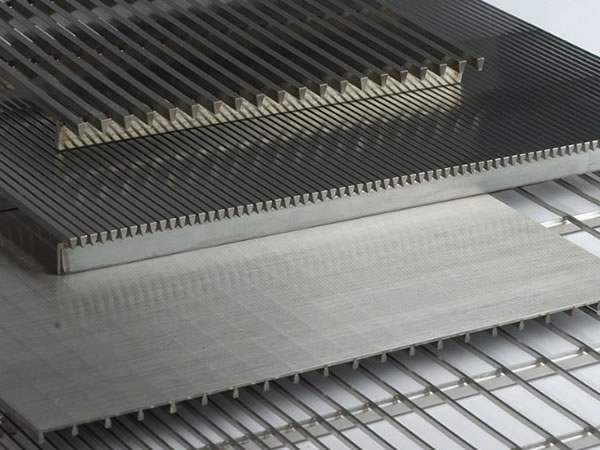

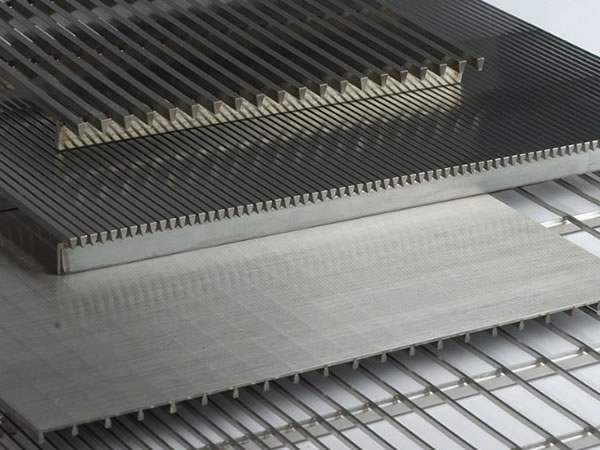

The manufacturing of a `wedge wire screen` is a highly specialized and precise process that ensures the product's superior performance and longevity. It begins with the selection of high-quality raw materials, predominantly stainless steel grades such as SS304, SS316, SS316L, and sometimes more specialized alloys like Duplex stainless steel or Hastelloy for highly corrosive or high-temperature applications. These materials are chosen for their excellent corrosion resistance, mechanical strength, and hygiene properties, crucial for various industrial environments. The core of the manufacturing process involves the formation of the V-shaped profile wire and the support rods. The V-profile wire, which forms the screen surface, is designed to minimize clogging and facilitate efficient backwashing due to its unique shape, allowing only two points of contact for filtered particles. This V-profile can be created through processes like cold rolling or drawing, ensuring consistent dimensions and surface finish. The support rods, typically round or triangular, are arranged longitudinally to provide structural integrity to the screen. The most critical stage is the resistance welding process, where the V-profile wires are precisely welded to the support rods at each intersection. This continuous slot design is created by the spacing between the V-wires, known as the slot opening, which is meticulously controlled during welding to meet specific filtration requirements. Advanced CNC welding machines are often employed to achieve the high precision and consistency required, ensuring uniform slot openings across the entire screen surface. After welding, the screen undergoes rigorous quality control and inspection. This includes dimensional checks to verify the slot size, diameter (for cylindrical screens), length, and overall conformity to design specifications. Surface finish inspection ensures there are no burrs or defects that could impede flow or create weak points. Material composition verification, hydrostatic testing for pressure applications, and structural integrity tests are also common to ensure the product meets stringent industry standards such as ISO 9001, ANSI/AWWA B100, and ASTM specifications. The manufacturing flexibility allows for various forms, including flat `wedge wire screen panel` for static filtration, cylindrical screens for well applications or rotary drums, and specialized shapes for sieves or baskets. The end-fittings or flanges are then added, often through welding, to allow for easy installation into existing systems. This meticulous process ensures that the final `wedge wire screen for sale` product offers maximum open area, superior strength, precise slot control, and excellent resistance to clogging and corrosion, translating into significant advantages such as energy savings due to reduced pressure drop and prolonged service life even in aggressive environments like those found in petrochemical processing, metallurgy, or water supply and drainage systems, where their robust design prevents premature wear and tear, reducing the need for frequent replacements and associated downtime.

Key Technical Parameters and Specifications for Wedge Wire Screens

Selecting the appropriate `wedge wire screen` requires a thorough understanding of its key technical parameters, which directly impact its performance and suitability for specific applications. These parameters define the physical characteristics and filtration capabilities of the screen. The most critical parameter is the slot opening, also known as aperture size or gap size, which determines the smallest particle size that can be effectively filtered or separated. Slot openings can range from as fine as 25 microns (0.001 inches) for precise filtration to several millimeters for coarse screening, and this precision is maintained through advanced manufacturing techniques. The profile wire type and dimensions (width and height of the V-shaped wire) influence the open area, strength, and flow characteristics. Common profile wire shapes include triangular (V-shape), which is standard, and sometimes modified profiles for specific flow patterns. The support rod type and spacing are equally important for structural integrity; these rods can be round, rectangular, or triangular, with spacing chosen to provide adequate support without compromising the open area. The material of construction is paramount, as it dictates the screen's resistance to corrosion, abrasion, temperature, and chemical attack. Stainless steel grades (304, 316L, 316) are standard, with 316L being preferred for highly corrosive environments due to its low carbon content. For extremely aggressive conditions, duplex stainless steels (e.g., 2205, 2507) or specialized alloys (e.g., Hastelloy, Monel) are employed. Screen dimensions, including diameter (for cylindrical screens), length, and panel size (for flat screens), are customized to fit specific equipment and process volumes. The surface finish is also a consideration, especially for hygienic applications in food, beverage, or pharmaceutical industries, where polished surfaces prevent bacterial growth and facilitate cleaning. The open area percentage, calculated as the total area of the slots divided by the total surface area, is a crucial indicator of flow capacity and efficiency; a higher open area generally means less pressure drop and higher throughput. Finally, end connections or fittings for cylindrical screens, such as flanges, threaded ends, or plain ends, are vital for seamless integration into existing pipe systems or vessels. Understanding these technical specifications allows engineers and procurement specialists to precisely match the `wedge wire screen for sale` to their filtration, separation, or dewatering requirements, ensuring optimal system performance and cost-effectiveness. For instance, a municipal water treatment plant requiring fine sand removal would opt for a small slot opening and 316L stainless steel for corrosion resistance, whereas a mining operation handling heavy slurries might prioritize larger slots and robust support rods to withstand abrasive conditions, making the precise specification critical for the successful deployment of any `wedge wire screen panel` or cylindrical element.

Typical Wedge Wire Screen Parameters

| Parameter |

Description |

Typical Range/Values |

| Material |

Corrosion-resistant alloys for durability |

SS 304, 316L, 316, Duplex SS 2205, 2507, Hastelloy, Monel |

| Slot Opening |

Precision-engineered filtration gap |

0.025 mm (25 microns) to 15 mm (custom available) |

| Profile Wire Size (WxH) |

Dimensions of the V-shaped wire |

e.g., 1.5x2.5mm, 2x3mm, 2.5x4mm, 3x5mm |

| Support Rod Size (WxH) |

Dimensions of the support rods |

e.g., 2.5x5mm, 3x6mm, 4x7mm (various shapes) |

| Rod Spacing |

Distance between support rods |

10 mm to 50 mm (customizable) |

| Open Area Percentage |

Total open slot area / total screen area |

Typically 10% to 60% (depends on slot/wire size) |

| Diameter (Cylindrical) |

External diameter for cylindrical screens |

25 mm to 1200 mm (1 inch to 48 inches) |

| Length |

Total length of screen segment |

Up to 6000 mm (20 feet) or joined segments |

| Form/Shape |

Configuration of the screen product |

Flat Panel, Cylinder, Cone, Sieve Bend, Basket, Nozzle |

| End Fittings |

Connection types for installation |

Flanged, Threaded, Welded Ring, Plain End, Customizable |

| Surface Finish |

Treatment of the screen surface |

Mill Finish, Pickled & Passivated, Electro-polished (for sanitary) |

Versatile Application Scenarios of Wedge Wire Screens

The adaptability and robust design of `wedge wire screen` products enable their use across an exceptionally broad spectrum of industrial applications, making them a cornerstone in modern processing and manufacturing. In the Water and Wastewater Treatment sector, they are indispensable for fine screening of raw water intake to protect pumps and downstream equipment, dewatering of sludge, sand and grit removal, and clarifying processes in municipal and industrial treatment plants. Their non-clogging design ensures continuous operation and reduced maintenance, which is critical for maintaining consistent water quality and compliance. Within the Oil and Gas Industry, `wedge wire screen` well screens are vital for sand control in oil, gas, and water wells, preventing formation particles from entering the wellbore, thereby extending pump life, maximizing flow rates, and improving overall well productivity. They are also utilized in completion string components, filter elements for frac water, and separation processes on offshore platforms, where their durability in corrosive downhole environments is paramount. The Mining and Minerals Processing industry benefits greatly from `wedge wire screen panel` and sieve bends for mineral sizing, aggregate washing, dewatering of slurries, and tramp material removal, leading to higher yield and cleaner separation of valuable minerals. The robust construction allows them to withstand abrasive materials and heavy loads typical of mining operations. In the Food and Beverage Industry, wedge wire screens are highly valued for their hygienic properties, ease of cleaning, and precise separation capabilities. Applications include sugar refining (centrifugal baskets), brewery mash tuns, fruit juice clarification, potato and vegetable washing, and general food processing for solid-liquid separation, ensuring product purity and compliance with strict sanitary regulations. The Chemical and Petrochemical Industries rely on these screens for catalytic support grids, reactor internal supports, heat exchanger strainers, and media retention, where their ability to withstand high temperatures, aggressive chemicals, and differential pressures is crucial for safety and operational efficiency. Furthermore, they find use in Pulp and Paper Mills for fiber recovery, bark dewatering, and pulp screening, contributing to efficient resource utilization and reduced environmental impact. The Power Generation sector employs `wedge wire screen for sale` for intake screens to protect cooling water systems from debris, and in various filtration duties within power plants. Even within the Architectural and Decorative fields, custom `wedge wire screen` can be found in facades, balustrades, and drainage systems, where their aesthetic appeal and functional durability are combined. This extensive range of applications underscores the versatility and indispensable nature of wedge wire technology in achieving efficient separation, filtration, and classification across virtually every major industrial domain, highlighting their critical role in optimizing processes and ensuring product integrity.

Technical Advantages and Performance Superiority of Wedge Wire Screens

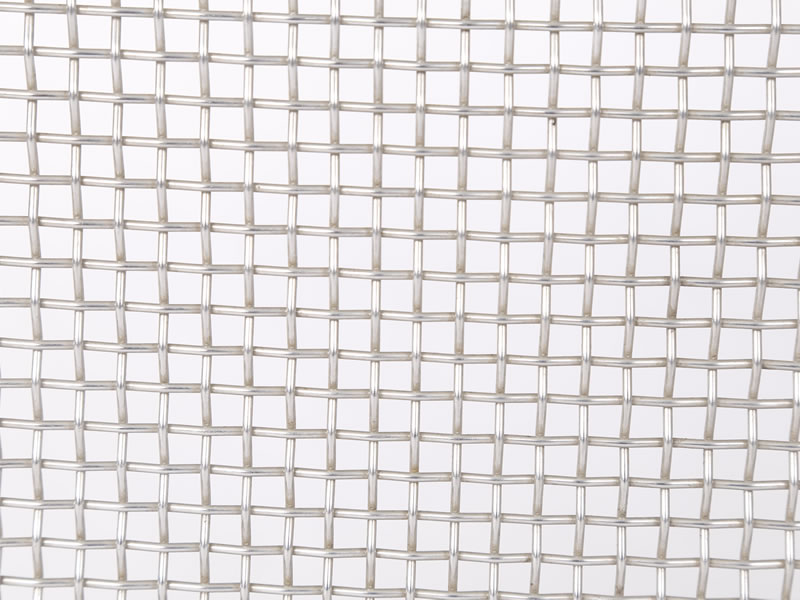

The distinctive design and robust construction of `wedge wire screen` products endow them with a host of technical advantages that translate directly into superior operational performance and significant long-term savings compared to alternative screening technologies. Perhaps the most prominent advantage is their non-clogging characteristic. The V-shaped profile wire creates a knife-edge opening that allows only two points of contact for solid particles. This design ensures that particles smaller than the slot pass through easily, while those larger are retained on the surface, with minimal opportunity to become lodged within the screen opening. This stands in stark contrast to woven mesh or perforated plates, which have flat openings or conical holes that can easily trap particles, leading to blinding and reduced flow. The continuous slot design further enhances this non-clogging feature. Secondly, `wedge wire screen` offers an exceptionally high open area. Because the support rods are spaced apart and the V-wires are oriented to maximize flow, wedge wire screens can achieve open areas significantly higher than those of perforated plates or even some woven meshes. A higher open area translates directly to a lower pressure drop across the screen, meaning less energy consumption for pumps and more efficient fluid flow, resulting in considerable energy savings and increased throughput for industrial processes. This also leads to a more uniform flow distribution over the screen surface. Thirdly, these screens possess superior mechanical strength and durability. The V-profile wires are resistance welded to every intersection of the support rods, creating a robust, unitary structure that can withstand high differential pressures, abrasive media, and extreme temperatures without deforming or breaking. This inherent strength ensures a longer service life, even in demanding applications like mining or high-pressure filtration, significantly reducing replacement costs and downtime for processes requiring a consistent supply of `wedge wire screen for sale`. Fourthly, their design facilitates efficient backwashing. The V-shaped openings widen towards the inside of the screen, meaning that backwashing operations can more effectively dislodge trapped particles, restoring the screen's flow capacity quickly and thoroughly. This ease of cleaning minimizes manual intervention and extends operational cycles between cleaning events. Lastly, the precise slot control achievable during manufacturing ensures consistent filtration quality. Manufacturers can achieve highly accurate slot openings from very fine to coarse, guaranteeing that the separation criteria are consistently met. This precision is critical for product quality, process efficiency, and compliance in industries such as pharmaceuticals and food processing. The combination of non-clogging efficiency, high open area, unparalleled strength, and ease of maintenance makes `wedge wire screen panel` and other configurations a preferred choice for engineers seeking reliable, cost-effective, and high-performance separation solutions, leading to optimized production, reduced operational expenses, and a higher return on investment over the product's extended lifespan.

Manufacturer Comparison and Selection Factors for Wedge Wire Screens

Choosing the right manufacturer for `wedge wire screen for sale` is a critical decision that significantly impacts the performance, longevity, and cost-effectiveness of your industrial operations. With numerous suppliers in the market, discerning the best fit requires careful consideration of several key factors that extend beyond just the initial purchase price. Firstly, Expertise and Experience are paramount. A reputable manufacturer should possess extensive experience specifically in the design and fabrication of `wedge wire screen` products. This includes a deep understanding of metallurgy, fluid dynamics, welding technologies, and the specific challenges of various industrial applications. Look for companies with a long service history and a proven track record of successful projects across diverse sectors like water treatment, oil & gas, mining, and food & beverage. Their experience directly translates into the ability to provide optimized solutions and troubleshoot potential issues proactively. Secondly, Quality Control and Certifications are non-negotiable. A top-tier manufacturer will adhere to stringent quality management systems such as ISO 9001, ensuring consistent product quality, traceability, and adherence to international standards. They should implement comprehensive testing procedures throughout the manufacturing process, from raw material inspection to final product verification, including dimensional checks, hydrostatic pressure testing, and material analysis. Certifications from recognized bodies like FDA (for food contact applications) or compliance with ANSI/AWWA standards (for water wells) further attest to their commitment to quality and safety. Thirdly, Customization Capabilities are crucial. Very few industrial applications are truly standard. A superior manufacturer will offer robust customization services, capable of designing and fabricating wedge wire screens to precise specifications regarding slot size, material, dimensions, shape (flat, cylindrical, conical), and end fittings. This flexibility ensures that the screen perfectly integrates with your existing equipment and optimizes performance for your unique process parameters, whether it's a specialized `wedge wire screen panel` or an intricate filter basket. Fourthly, Technical Support and After-Sales Service are vital for long-term operational success. A reliable supplier provides expert technical consultation during the design and selection phase, assisting in specifying the ideal screen for your needs. Furthermore, they should offer responsive after-sales support, including installation guidance, troubleshooting, and maintenance advice. This level of support ensures that you can maximize the lifespan and efficiency of your wedge wire screens and resolve any operational challenges swiftly. Fifthly, assess their Manufacturing Technology and Facilities. Modern, well-equipped facilities utilizing advanced welding techniques (e.g., resistance welding, laser welding) and precision machinery indicate a manufacturer's commitment to quality and efficiency. A strong manufacturing infrastructure can also contribute to more competitive pricing and reliable delivery schedules. Finally, consider Industry Reputation and Client Feedback. Review testimonials, case studies, and industry references to gauge the manufacturer's standing in the market. A company with a strong reputation for reliability, quality, and customer satisfaction is generally a safer and more dependable choice. By diligently evaluating these factors, businesses can forge partnerships with manufacturers who not only supply high-quality `wedge wire screen` products but also act as strategic partners in enhancing their filtration and separation processes, ensuring operational excellence and sustained productivity over the product's extended service life.

Tailored Customization Solutions for Specific Applications

One of the most significant advantages of `wedge wire screen` technology is its inherent flexibility for customization, allowing manufacturers to tailor solutions precisely to the unique demands of virtually any industrial application. This bespoke approach ensures optimal performance, seamless integration, and maximum efficiency, distinguishing `wedge wire screen for sale` from off-the-shelf components. Customization begins with the material selection, where engineers can specify various grades of stainless steel (SS304, SS316, SS316L) or exotic alloys (Duplex, Hastelloy, Monel) based on factors such as operating temperature, chemical compatibility, corrosive media, and abrasive conditions. For instance, a screen destined for a highly acidic chemical process would require Hastelloy, while a sanitary application in dairy processing would necessitate polished SS316L. The slot opening is another critical parameter that can be finely tuned from as little as 25 microns for ultra-fine filtration to several millimeters for coarse separation, ensuring precise particle retention or removal specific to the process requirements. This precision is vital in industries like pharmaceuticals where particle size distribution is strictly controlled. Profile wire and support rod dimensions and spacing can also be customized to optimize the open area and mechanical strength. Thicker profile wires and more robust support rods would be selected for high-pressure or heavy-load applications, such as in mining dewatering, to ensure the screen can withstand the operational stresses. Furthermore, `wedge wire screen` can be fabricated into an extensive array of shapes and configurations beyond standard cylindrical or flat forms. This includes conical screens, basket strainers, sieve bends, header laterals, nozzles, and custom-shaped elements designed to fit existing vessels, tanks, or process lines. Each shape serves a specific purpose; for example, sieve bends are designed for high-capacity dewatering and classification without moving parts, while header laterals are ideal for media retention in ion exchange or carbon filtration systems. End connections and fittings are also highly customizable, including various flange types (ANSI, DIN, JIS), threaded ends, plain ends for welding, or specialized quick-release couplings, ensuring compatibility with diverse piping and equipment interfaces. Surface treatments, such as pickling and passivation for enhanced corrosion resistance or electro-polishing for sanitary applications, further extend the customization possibilities, providing a smoother surface that resists biofouling and facilitates cleaning. The collaborative process between the client and the manufacturer’s engineering team is fundamental to developing these tailored solutions. By sharing detailed process data, existing equipment specifications, and performance objectives, clients enable manufacturers to design and produce `wedge wire screen panel` or other custom configurations that are not just components, but optimized solutions engineered to solve specific industrial challenges, thereby maximizing efficiency, extending equipment life, and ultimately reducing operational costs. This adaptability ensures that wedge wire technology remains at the forefront of industrial filtration and separation.

Real-World Application Cases and Success Stories

The practical effectiveness of `wedge wire screen` technology is best demonstrated through its successful implementation in various real-world industrial scenarios, showcasing tangible benefits in terms of efficiency, cost savings, and operational reliability. One compelling example comes from the municipal wastewater treatment sector. A large metropolitan treatment plant faced chronic clogging issues with traditional perforated screens in their grit removal chambers, leading to frequent downtime for manual cleaning and increased maintenance costs. After consulting with a specialized manufacturer of `wedge wire screen for sale`, they replaced their existing screens with custom-designed `wedge wire screen panel` units with specific slot openings. The V-shaped wire design drastically reduced blinding, allowing for continuous operation. Within six months, the plant reported a 70% reduction in screen cleaning frequency, a 30% decrease in overall maintenance expenditures, and a noticeable improvement in grit removal efficiency, leading to smoother downstream processes and compliance with discharge regulations. Another impactful case is in the oil and gas industry. An offshore drilling operation in the North Sea encountered severe sand production issues in a mature well, significantly reducing oil flow and causing excessive wear on submersible pumps. Implementing a high-strength SS316L `wedge wire screen` well screen with an optimized slot configuration provided superior sand control. This intervention resulted in a 45% increase in oil production from that well due to sustained flow rates and a 60% extension in the lifespan of their downhole pumps, leading to millions of dollars in operational savings and deferred equipment replacement. In the food and beverage industry, a major sugar refinery sought to improve the purity and yield of their sugar crystals. Their old centrifugal baskets, made of woven mesh, suffered from blinding and inconsistent separation. They upgraded to precisely manufactured wedge wire centrifugal baskets. The non-clogging surface and uniform slot openings of the new baskets led to a 15% improvement in sugar crystal purity and a 5% increase in overall yield. The ease of cleaning for the wedge wire also significantly reduced CIP (Clean-In-Place) cycles, enhancing hygiene and reducing operational costs. A mining company struggling with inefficient dewatering of their coal slurry installed large `wedge wire screen` sieve bends. These static dewatering screens, without any moving parts, effectively separated water from coal fines with minimal energy consumption. The result was a 25% increase in dewatered coal throughput and a substantial reduction in the moisture content of the final product, leading to higher quality coal and lower transportation costs. These diverse application cases unequivocally demonstrate that investing in high-quality, purpose-built `wedge wire screen` solutions delivers tangible and measurable benefits, proving their value as a superior filtration and separation technology across a wide array of demanding industrial environments, and reinforcing their indispensable role in optimizing processes for enhanced productivity and reduced operational overhead.

Authoritativeness and Trustworthiness: FAQs, Delivery, and Warranty

Establishing trust and authority is paramount in the B2B sector, particularly when sourcing critical components like `wedge wire screen`. A reputable supplier backs its products with transparent information, robust support, and verifiable credentials. This section addresses common inquiries, provides clarity on logistical aspects, and outlines guarantees to foster confidence among potential buyers seeking `wedge wire screen for sale`.

Frequently Asked Questions (FAQs)

Q1: What makes wedge wire screens superior to woven mesh or perforated plates for filtration?

A1: The primary superiority of `wedge wire screen` lies in its unique V-shaped wire profile and continuous slot design. Unlike woven mesh, which has square openings that can trap particles, or perforated plates with conical holes prone to blinding, wedge wire screens offer a two-point contact filtration surface. This minimizes the chance of particles becoming lodged, ensuring a non-clogging characteristic. The V-shape widens internally, facilitating efficient backwashing and dislodging of trapped solids. Furthermore, wedge wire screens boast a significantly higher open area, leading to lower pressure drop, increased flow rates, and reduced energy consumption. Their robust, all-welded construction provides superior mechanical strength, allowing them to withstand higher differential pressures and abrasive conditions, resulting in a much longer service life and less downtime compared to the less durable, more prone-to-deformation woven mesh or perforated plates. This inherent durability and efficiency make them the preferred choice for demanding industrial applications requiring reliable and continuous operation, ensuring a superior return on investment over the lifecycle of the product due to reduced maintenance and replacement frequencies.

Q2: How do I determine the correct slot opening for my specific application?

A2: Determining the optimal slot opening for a `wedge wire screen` is a critical step that involves several factors, primarily the size and characteristics of the particles you need to separate, the required flow rate, and the desired purity of the filtered liquid or material. Our experienced technical sales team can assist you in this selection process. Generally, you need to consider the particle size distribution of your raw material. For simple retention of larger particles, the slot opening can be slightly smaller than the smallest particle you wish to retain. For fine filtration, it might need to be significantly smaller. Factors such as the viscosity of the fluid, the concentration of solids, and the potential for particle agglomeration also play a role. We recommend providing detailed information about your process, including fluid properties, typical particle sizes, temperature, pressure, and desired filtration efficiency. Our engineers utilize this data, combined with their extensive experience and potentially pilot testing results, to recommend the precise slot size and screen configuration that will deliver the most efficient and cost-effective separation for your unique `wedge wire screen panel` or cylindrical screen application. Incorrect slot sizing can lead to premature clogging, reduced throughput, or insufficient filtration, making this a crucial design consideration that warrants expert consultation.

Q3: What materials are available for wedge wire screens, and how do I choose the right one?

A3: `Wedge wire screen` products are available in a range of high-performance materials, primarily various grades of stainless steel, to suit diverse industrial environments. The most common materials include SS304, SS316, and SS316L. SS304 is a general-purpose stainless steel offering good corrosion resistance and strength for mild applications. SS316 and especially SS316L (low carbon content) provide superior corrosion resistance, particularly against chlorides and acidic environments, making them ideal for water treatment, marine, and some chemical applications. For highly aggressive or extreme conditions, such as high concentrations of specific chemicals, elevated temperatures, or highly abrasive slurries, we offer specialized alloys like Duplex Stainless Steels (e.g., 2205, 2507) known for their excellent strength and resistance to stress corrosion cracking, as well as exotic alloys like Hastelloy or Monel for the most severe corrosive or high-temperature duties. The choice of material depends heavily on the chemical composition of the media being processed, the operating temperature, pressure, and the presence of abrasive particles. Our technical experts can guide you through the material selection process based on your specific operational parameters and the expected chemical and physical stresses the `wedge wire screen for sale` will encounter, ensuring optimal performance and maximum service life in your unique industrial setup.

Delivery Timelines and Logistics

Understanding delivery timelines and logistical capabilities is vital for project planning and operational continuity. Our commitment to efficiency and customer satisfaction extends to our robust supply chain management. For standard `wedge wire screen` products, typical lead times can range from 2 to 4 weeks, depending on the volume and current production schedule. However, for highly customized `wedge wire screen panel` or specialized configurations requiring intricate fabrication or unique material procurement, lead times may extend to 6-10 weeks. We understand that project deadlines are often tight, and we work closely with our clients to provide accurate lead time estimates at the quotation stage. We offer various shipping options, including sea freight for cost-effectiveness on large orders and air freight for urgent requirements, ensuring global reach. Our logistics team handles all necessary documentation, customs procedures, and packaging to ensure your `wedge wire screen` products arrive safely and on time, anywhere in the world. We also provide order tracking and proactive communication throughout the shipping process, keeping you informed from production to delivery. Clients are encouraged to discuss their specific delivery needs during the inquiry phase so that we can tailor a logistical plan that best meets their project timelines and budgetary considerations, reinforcing our reputation as a reliable supplier of high-quality industrial filtration components.

Quality Assurance and Warranty Commitment

Our dedication to quality and customer satisfaction is reflected in our comprehensive quality assurance protocols and generous warranty commitments for every `wedge wire screen` we manufacture. We operate under a strict ISO 9001 certified quality management system, which governs every stage of our production, from raw material inspection and in-process controls to final product testing. Each `wedge wire screen for sale` undergoes rigorous inspection for dimensional accuracy, slot opening consistency, weld integrity, and surface finish. We conduct various tests, including material chemical analysis, hydrostatic pressure testing for critical applications, and visual inspections to ensure every product meets or exceeds industry standards and client specifications. We are confident in the durability and performance of our `wedge wire screen` products, which is why we offer a standard warranty against manufacturing defects and material failures under normal operating conditions. The specific warranty period and terms are provided with each quotation and may vary based on product type and application severity. In the unlikely event of a defect covered by our warranty, we commit to prompt repair or replacement, minimizing any disruption to your operations. Our responsive customer support team is always available to address any concerns or provide technical assistance, underscoring our commitment to being a trusted partner. We believe that a strong warranty and a robust quality assurance program are not just contractual obligations, but fundamental pillars of the trustworthiness and long-term relationships we build with our B2B clients, ensuring that your investment in our `wedge wire screen panel` solutions is protected and delivers consistent, reliable performance for years to come.

References and Further Reading

-

[1] Journal of Water Process Engineering: "Advances in Wedge Wire Screen Technology for Wastewater Treatment: A Review of Performance and Applications." Available at: ScienceDirect - Journal of Water Process Engineering (Specific article link not available without subscription, general journal link provided.)

-

[2] Filtration+Separation Magazine: "The Role of Profile Wire Screens in Enhancing Industrial Filtration Efficiency." Available at: Filtration+Separation Magazine (General magazine link provided, specific article may vary.)

-

[3] SPE (Society of Petroleum Engineers) Journal: "Optimizing Sand Control Using Advanced Well Screen Technologies." Available at: Society of Petroleum Engineers (General society link provided, specific technical papers require membership/purchase.)