In the vast landscape of modern industry and aquaculture, the role of wire mesh fabricators is paramount. These specialized entities are the backbone of countless applications, transforming raw materials into sophisticated mesh products that underpin infrastructure, safeguard environments, and drive innovative solutions. From critical filtration systems in industrial complexes to robust containment units in marine farming, the versatility and durability of expertly crafted wire mesh are indispensable. This comprehensive guide delves into the intricate world of wire mesh fabrication, exploring its diverse applications, the technical prowess required, and the specific advantages offered by leading manufacturers in delivering high-quality, reliable products.

The Evolving Landscape of Wire Mesh Fabrication

The global demand for wire mesh products continues to surge, driven by expanding sectors such as construction, agriculture, environmental protection, and, notably, aquaculture. Modern wire mesh fabricators are at the forefront of this growth, leveraging advanced manufacturing techniques and innovative materials to meet diverse market needs. Key industry trends include the increasing adoption of automated production lines, the development of highly corrosion-resistant materials, and a growing emphasis on sustainable manufacturing practices. The ability to produce bespoke solutions, coupled with stringent quality control, distinguishes leading fabricators in a competitive market.

The market for wire mesh is projected to grow significantly, with a compound annual growth rate (CAGR) of over 4% from 2023 to 2030, according to various market research reports. This growth is fueled by infrastructure development in emerging economies, the need for enhanced security solutions, and the expansion of sustainable farming practices, including aquaculture. This highlights the critical role of versatile and adaptable wire mesh fabricators.

Wire mesh comes in an astonishing array of configurations, each designed for specific performance characteristics. The primary categories include woven wire mesh, welded wire mesh, expanded metal mesh, and perforated metal mesh. Each type offers distinct advantages:

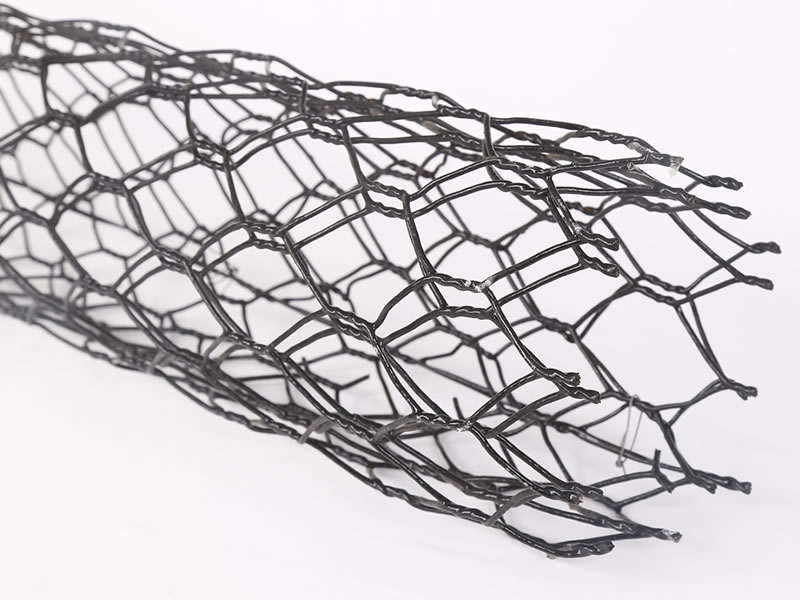

- Woven Wire Mesh: Produced by weaving wires over and under each other, similar to fabric. It offers precise aperture sizes and flexibility, commonly used in filtration, sieving, and decorative applications.

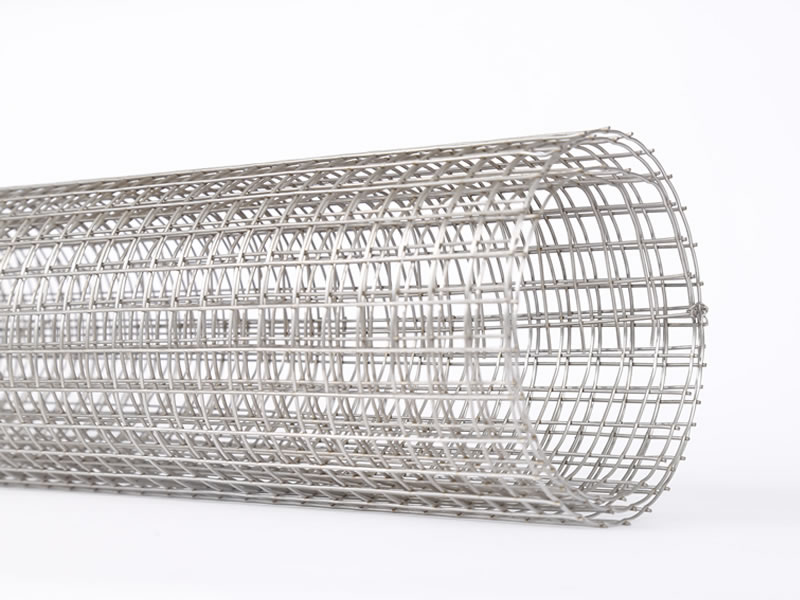

- Welded Wire Mesh: Manufactured by resistance welding wires at their intersections, creating a rigid and strong structure. Ideal for security fencing, concrete reinforcement, and animal enclosures.

- Expanded Metal Mesh: Created by slitting and stretching a solid metal sheet, forming a seamless, joint-free mesh. Known for its strength-to-weight ratio and anti-skid properties, used in walkways, grates, and security screens.

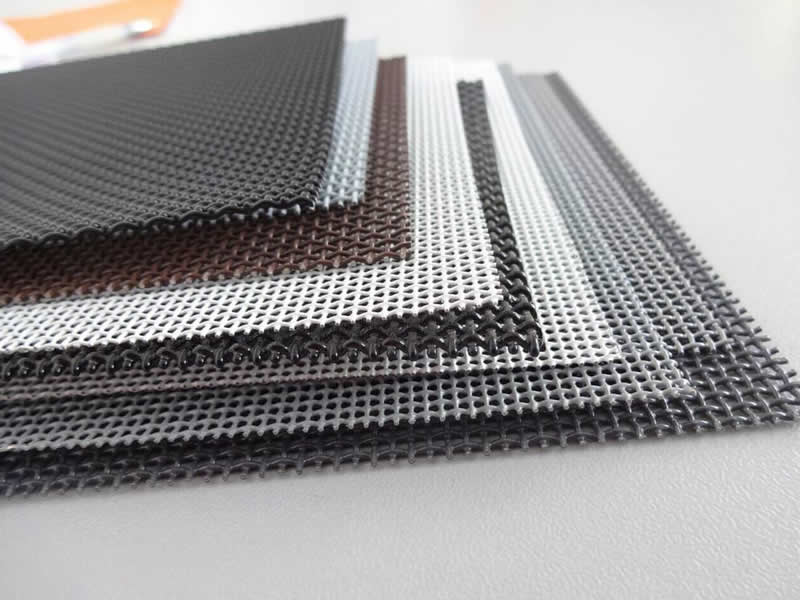

- Perforated Metal Mesh: Produced by punching holes into a solid metal sheet. Offers a wide range of hole shapes and patterns, suitable for architectural facades, acoustic panels, and decorative elements.

Key technical parameters define the properties and suitability of wire mesh for various applications. Understanding these parameters is crucial when sourcing from wire mesh fabricators:

- Mesh Size (Aperture): The clear opening between adjacent parallel wires. Measured in inches, millimeters, or mesh count (number of openings per linear inch). Smaller apertures are critical for fine filtration.

- Wire Diameter (Gauge): The thickness of the individual wires. Thicker wires provide greater strength and durability but reduce the open area.

- Material: Common materials include stainless steel (304, 316, 316L for corrosion resistance), galvanized steel (for rust prevention), plain steel (for general purpose), copper, brass, aluminum, and various plastics like HDPE and PVC.

- Open Area: The percentage of the total mesh area that is open space. Higher open area allows for greater flow rates in filtration or better light/air penetration.

- Weave Type: For woven mesh, types include plain weave, twilled weave, Dutch weave (plain and twilled), each offering different strengths and filtration capabilities.

- Roll Width & Length: Standard and custom dimensions for ease of installation and reduced waste.

Here’s a comparative table illustrating common parameters for different types of wire mesh supplied by wire mesh fabricators:

| Parameter |

Woven Wire Mesh |

Welded Wire Mesh |

Expanded Metal Mesh |

Perforated Metal Mesh |

| Structure |

Interlaced wires |

Wires welded at intersections |

Slit and stretched sheet |

Punched holes in sheet |

| Strength |

Moderate to High (depends on weave) |

High (rigid) |

High (seamless) |

Moderate to High (depends on hole pattern) |

| Flexibility |

High |

Low (rigid) |

Low to Moderate |

Low |

| Aperture Precision |

Very High |

High |

Moderate (variable) |

Very High |

| Typical Materials |

SS, Galvanized, Copper, Brass |

SS, Galvanized, Plain Steel, PVC Coated |

SS, Carbon Steel, Aluminum |

SS, Carbon Steel, Aluminum, Plastics |

| Open Area Range |

20% - 90% |

40% - 95% |

50% - 85% |

3% - 80% |

| Common Uses |

Filtration, Sieving, Fencing |

Security, Reinforcement, Cages |

Walkways, Grates, Security |

Screens, Filters, Architectural |

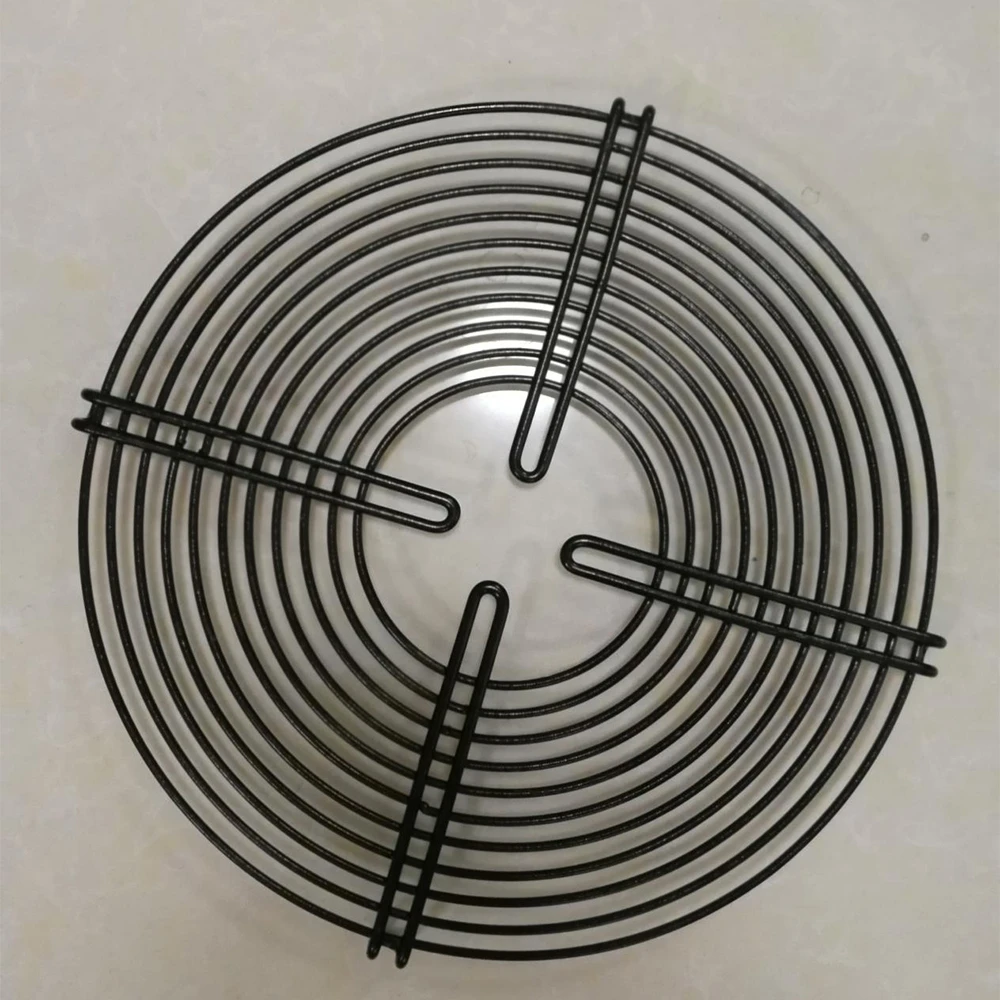

Spotlight Product: Oyster Growth Basket

A prime example of specialized wire mesh fabrication is the Oyster Growth Basket. Designed specifically for the aquaculture industry, these baskets facilitate efficient and sustainable oyster farming by providing an optimal environment for growth while protecting the oysters from predators and harsh environmental conditions. They are a testament to how advanced wire mesh fabricators adapt their capabilities to niche markets.

- Product Name: Oyster Growth Basket

- Product URL: https://www.hebei-wiremesh.com/oyster-growth-basket.html

- Primary Material: High-Density Polyethylene (HDPE) or PVC-Coated Galvanized Steel Wire. HDPE is preferred for its inertness, buoyancy, and excellent resistance to marine environments. PVC-coated wire offers robust strength and corrosion resistance.

- Mesh Type: Typically welded or extruded mesh, ensuring rigidity and precise mesh openings.

- Key Features:

- Durability: Resistant to UV degradation, saltwater corrosion, and physical impact.

- Optimal Flow: Designed with specific mesh sizes to allow proper water circulation and nutrient flow while retaining oysters securely.

- Predator Protection: Robust construction prevents access by crabs, snails, and other common oyster predators.

- Stackable & Modular: Often designed for easy stacking and connection, optimizing farm layouts and handling efficiency.

- Environmentally Friendly: HDPE is recyclable and does not leach harmful chemicals into the marine environment.

The creation of a high-quality Oyster Growth Basket by proficient wire mesh fabricators involves a meticulous multi-stage process, ensuring durability, functionality, and longevity in demanding marine environments. While specific steps may vary depending on the material (HDPE vs. PVC-coated wire), the core principles of precision and quality remain constant.

HDPE Oyster Basket Manufacturing Flow:

-

Material Extrusion & Net Formation:

High-quality virgin HDPE pellets are fed into an extruder. Under high temperature and pressure, the polymer is melted and forced through a die to form a continuous sheet or net. This process allows for precise control over mesh size and strand thickness.

(Key Node: Polymer Melting & Die Formation - Ensures uniform material distribution and initial mesh structure.)

-

Cooling & Stabilization:

The hot extruded net passes through a cooling bath (typically water) to rapidly solidify the HDPE. This step is critical for stabilizing the mesh structure and preventing deformation.

(Key Node: Rapid Cooling - Prevents shrinkage and maintains dimensional stability.)

-

Stretching (Orientation):

The cooled net is then stretched in one or two directions (uniaxial or biaxial orientation). This process aligns the polymer chains, significantly enhancing the mesh's tensile strength, stiffness, and resistance to tearing and UV degradation. This is a critical step for durability in marine conditions.

(Key Node: Polymer Orientation - Maximizes strength and UV resistance.)

-

Cutting & Shaping:

The continuous mesh roll is precisely cut into specific dimensions required for the basket components (e.g., sides, bottom, lid). Advanced CNC cutting machines ensure accuracy and minimize material waste.

(Key Node: Precision Cutting - Ensures accurate component sizing for assembly.)

-

Assembly & Welding:

Individual mesh panels are assembled into the basket shape. For HDPE, this typically involves ultrasonic welding or heat welding, creating strong, seamless bonds at the joints. Latches, hinges, and flotation components are also integrated at this stage.

(Key Node: Ultrasonic/Heat Welding - Creates strong, waterproof, and durable basket structure.)

-

Quality Control & Testing:

Each basket undergoes rigorous quality checks. This includes visual inspection for defects, dimensional verification (against design specifications), and functional testing of latches and hinges. Resistance to UV exposure, impact resistance, and material strength are also periodically tested on samples.

(Key Node: Multi-Point Quality Assurance - Ensures product meets performance and longevity standards.)

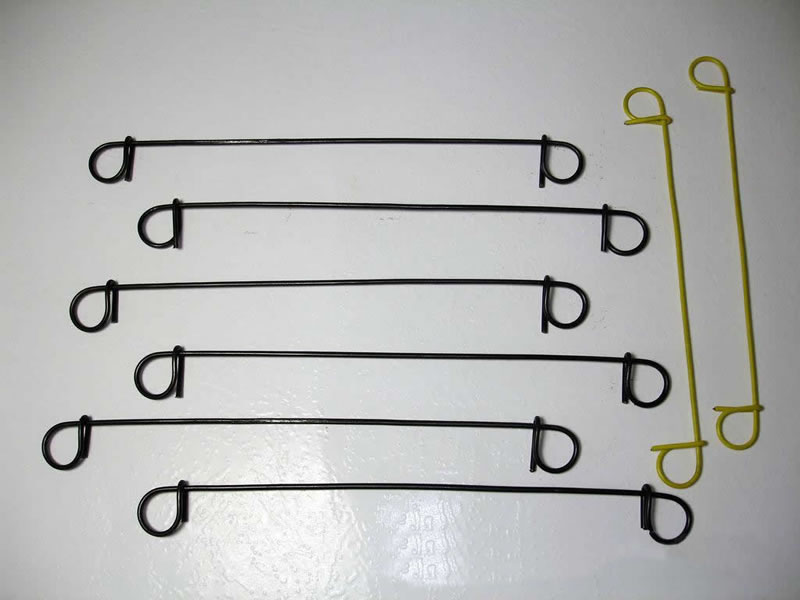

For PVC-coated wire baskets, the process would involve wire drawing, welding of the galvanized wire mesh, and then a subsequent PVC coating process (fluidized bed dipping or extrusion coating) followed by forming and assembly.

Testing Standards and Lifespan:

Reputable wire mesh fabricators adhere to strict international standards to ensure product quality and safety. For Oyster Growth Baskets, relevant standards include:

- ISO 9001: For Quality Management Systems, ensuring consistent production quality.

- ASTM Standards: For material properties, such as tensile strength, impact resistance, and UV stability of HDPE.

- FDA Compliance: While not directly consumed, materials used in aquaculture equipment that come into contact with aquatic life may need to meet certain non-toxic material standards, aligning with FDA or similar food-contact regulations for plastics if applicable.

An Oyster Growth Basket manufactured from high-grade, UV-stabilized HDPE typically boasts an impressive lifespan of 10-15 years, even in harsh marine conditions. This longevity significantly reduces replacement costs for aquaculture operations.

Applicable Industry & Advantages:

The primary applicable industry for Oyster Growth Baskets is, unequivocally, Aquaculture. Within this sector, the baskets offer distinct advantages:

- Enhanced Growth Rates: The optimal mesh size allows for excellent water flow, bringing nutrients to the oysters and flushing out waste, leading to faster and healthier growth.

- Predator Protection: The robust construction acts as a formidable barrier against common oyster predators, significantly reducing mortality rates.

- Improved Meat Quality: By keeping oysters off the seabed, the baskets promote cleaner, better-formed shells and higher meat yields, leading to premium market value.

- Ease of Management: Stackable and modular designs facilitate efficient handling, inspection, and harvesting, reducing labor costs.

- Environmental Stewardship: Durable, non-toxic materials like HDPE minimize environmental impact compared to traditional methods that might involve single-use plastics or less durable materials.

While the Oyster Growth Basket is specific to aquaculture, the underlying expertise in material selection, precision fabrication, and quality control from wire mesh fabricators extends to other industries. For instance, the demand for highly corrosion-resistant mesh in petrochemical filtration or durable, long-lifespan mesh in water treatment facilities shares common requirements with aquaculture equipment regarding material integrity and structural resilience.

Oyster Growth Basket - Typical Specifications

| Parameter |

Typical Range/Description |

Benefit for Oyster Farming |

| Material |

UV-Stabilized HDPE (High-Density Polyethylene) or PVC-Coated Galvanized Wire |

Superior corrosion resistance, non-toxic, long service life, environmental compatibility. |

| Mesh Size (Aperture) |

3mm, 6mm, 9mm, 12mm, 18mm, 23mm (variable based on oyster stage) |

Optimized water flow, nutrient delivery, waste removal; prevents small oyster escape and predator entry. |

| Dimensions (L x W x H) |

Commonly 500x500x100mm, 1000x500x100mm (customizable) |

Accommodates varying oyster densities, optimized for handling and stacking. |

| Buoyancy |

Designed for surface or submerged farming, often with integrated floats. |

Facilitates easy access for maintenance and harvesting; allows for flexible farming methods (e.g., flip-farming). |

| UV Resistance |

Excellent (rated for 10+ years direct sunlight exposure) |

Prevents material degradation, ensuring long-term durability in outdoor marine environments. |

| Weight (Empty) |

Lightweight (e.g., 2-5 kg depending on size and material) |

Easy to handle, reduces labor strain during deployment and harvesting. |

| Operating Temperature |

-30°C to +80°C |

Withstands a wide range of water temperatures without degradation. |

| Joining Method |

Ultrasonic welding or heat fusion (for HDPE); Welding (for wire) |

Strong, seamless joints that resist breakage and predator entry. |

Selecting the Right Wire Mesh Fabricators: A Comparison Framework

Choosing the right wire mesh fabricator is critical for the success of any project, especially for specialized applications like aquaculture. A thorough evaluation involves looking beyond just price to assess capabilities, quality control, and customer support.

Comparison Criteria for Wire Mesh Fabricators

| Criteria |

Leading Fabricator (e.g., Hebei Wire Mesh expertise) |

Standard Fabricator |

| Material Sourcing & Quality |

Uses only prime, certified virgin raw materials (e.g., UV-stabilized HDPE, marine-grade stainless steel). Strong supplier relationships & material testing. |

May use recycled or lower-grade materials; less stringent material incoming inspection. |

| Manufacturing Process |

Automated production lines, precision welding/extrusion, advanced CNC cutting, specialized forming capabilities. Adherence to ISO 9001. |

Manual processes, older machinery, less precise fabrication, variable consistency. |

| Customization Capabilities |

Extensive R&D, design engineers, ability to produce custom mesh sizes, shapes, materials, and integrate features (e.g., specific latch designs for oyster baskets). |

Limited customization, primarily standard sizes and types; may require external tooling. |

| Quality Control & Testing |

In-process checks, post-production testing (dimensional, tensile, UV, corrosion resistance), independent lab certifications. Full traceability of batches. |

Basic visual inspection, limited or no laboratory testing. |

| Experience & Track Record |

Many years in specific industries (e.g., aquaculture), proven application cases, strong client testimonials, industry recognition. |

General experience, fewer specialized application examples. |

| Technical Support & After-Sales |

Dedicated technical team, design consultation, installation guidance, comprehensive warranty, quick response to issues. |

Limited support, basic warranty, slower response times. |

| Delivery & Logistics |

Efficient supply chain, global shipping capabilities, adherence to agreed delivery schedules. |

Potential for delays, limited shipping options. |

A leading wire mesh fabricator will demonstrate superior expertise in material science, engineering design, and production efficiency. For instance, in manufacturing Oyster Growth Baskets, their proficiency in utilizing UV-stabilized HDPE, ensuring precise mesh openings for optimal water flow, and designing robust, easy-to-handle components is paramount. Their commitment to international standards like ISO 9001 and extensive R&D capabilities for custom solutions position them as reliable partners.

Tailored Solutions: Custom Wire Mesh Fabrication

Many projects require more than off-the-shelf solutions. Leading wire mesh fabricators excel in providing custom fabrication services, precisely tailoring products to unique specifications. This includes:

- Material Selection: Advising on the best material for specific environmental conditions (e.g., marine, acidic, high-temperature).

- Mesh Configuration: Designing custom mesh sizes, wire diameters, and open areas for optimal performance in filtration, separation, or containment.

- Form & Function: Fabricating complex shapes, integrating specific fittings, or adding specialized coatings (e.g., PVC, powder coating) for enhanced durability or aesthetics.

- Prototyping & Testing: Developing prototypes and conducting rigorous tests to ensure the custom product meets all performance criteria before full-scale production.

For aquaculture, this means the ability to produce Oyster Growth Baskets with specialized dimensions to fit particular farm layouts, or unique latching mechanisms for specific handling needs. This level of customization ensures maximum efficiency and longevity for the end-user.

Real-World Impact: Application Cases for Oyster Growth Basket

The impact of well-fabricated Oyster Growth Baskets is evident in the burgeoning success of sustainable oyster farms worldwide. Here are illustrative application cases:

- Case Study 1: Coastal Oyster Farm, Pacific Northwest, USA

A large-scale oyster farm in the Pacific Northwest transitioned from traditional on-bottom methods to a floating system utilizing custom-designed Oyster Growth Baskets. The previous method resulted in significant predator loss (up to 30% from Dungeness crabs and sea stars) and inconsistent shell quality. After implementing the new system with robust HDPE baskets (12mm mesh for mature oysters), predator losses plummeted to less than 5%. Furthermore, improved water flow led to a 15% reduction in growth time to market size and a noticeable improvement in shell uniformity and meat yield, enhancing premium market value. The farm reported an ROI within 3 years due to reduced losses and increased productivity.

- Case Study 2: Estuary Hatchery & Nursery, Chesapeake Bay, USA

A new oyster hatchery and nursery operation required specialized baskets for early-stage spat. They needed very fine mesh (3mm and 6mm) to contain delicate spat while ensuring sufficient plankton flow. A specialized wire mesh fabricator provided custom-sized mini-baskets made from UV-stabilized HDPE, designed to fit into their nursery tanks and withstand frequent handling. The baskets proved highly effective, supporting a survival rate of over 90% for spat, a critical factor in successful oyster aquaculture.

- Case Study 3: Offshore Oyster Farm, Atlantic Coast, Europe

An innovative offshore oyster farm needed extremely durable baskets capable of withstanding strong currents and rough seas. They opted for PVC-coated galvanized steel wire baskets from a reputable wire mesh fabricator. These baskets were designed with reinforced frames and secure latching mechanisms. After two years of continuous deployment, the baskets showed minimal wear and tear, demonstrating exceptional resilience against environmental stressors, ensuring consistent production even in challenging open-water conditions.

Frequently Asked Questions (FAQ) about Wire Mesh Fabricators and Oyster Baskets

Here are answers to common questions regarding wire mesh fabrication and our Oyster Growth Baskets:

- Q1: What materials are commonly used by wire mesh fabricators for corrosion resistance?

- A1: For high corrosion resistance, especially in marine or chemical environments, leading wire mesh fabricators commonly use materials such as Stainless Steel (grades 304, 316, 316L), High-Density Polyethylene (HDPE), and PVC-coated galvanized steel. Each offers specific benefits: Stainless steel for strength and broad chemical resistance; HDPE for inertness, UV stability, and buoyancy in water; and PVC coating for excellent saltwater and abrasion resistance over galvanized steel.

- Q2: How do you ensure the precision of mesh size for filtration applications?

- A2: Precision is paramount for filtration. We employ advanced weaving and welding machinery with precise control mechanisms. For woven mesh, specific loom settings are used. For welded mesh, computer-controlled welding robots ensure exact spacing. Post-production, mesh is rigorously inspected using optical comparators and digital calipers to verify aperture dimensions against specified tolerances, often adhering to ISO 9044 or ASTM E2016 standards.

- Q3: What manufacturing processes do you utilize for bespoke wire mesh solutions?

- A3: Our manufacturing processes for bespoke solutions include:

- Automated Weaving: For intricate woven patterns and precise mesh counts.

- Precision Resistance Welding: For strong, consistent welded mesh panels.

- High-Speed Extrusion: For continuous plastic mesh production with controlled dimensions.

- CNC Cutting & Forming: For accurate shaping, bending, and cutting of mesh into complex components.

- Plastic Injection Molding: For integrated components like latches and hinges on Oyster Baskets.

- Surface Treatment: Hot-dip galvanizing, PVC coating, powder coating for enhanced durability and specific aesthetic requirements.

- Q4: What is the typical lifespan of an Oyster Growth Basket, and how is it maintained?

- A4: An Oyster Growth Basket manufactured from high-grade, UV-stabilized HDPE typically has a lifespan of 10-15 years in marine environments. Maintenance is minimal but crucial: regular cleaning to remove biofouling (e.g., barnacles, algae) and periodic checks of latches and hinges. Cleaning is often done by tumbling machines or pressure washing, which also serves to "condition" the oysters, making them more robust.

- Q5: Are your Oyster Growth Baskets suitable for all stages of oyster growth?

- A5: Yes, our Oyster Growth Baskets are available with various mesh sizes (e.g., 3mm, 6mm, 9mm, 12mm, 18mm, 23mm) to accommodate different stages of oyster growth, from spat (juvenile oysters) to market-size adults. Farmers can transfer oysters to larger mesh baskets as they grow, optimizing flow and growth rates while ensuring containment.

- Q6: What are the delivery lead times and warranty terms for your products?

- A6: Delivery lead times vary based on product type, customization, and order volume. For standard products, it typically ranges from 2-4 weeks. Custom orders may require 4-8 weeks, depending on complexity. We provide detailed lead time estimates with each quote. All our products, including Oyster Growth Baskets, come with a comprehensive 5-year limited warranty against manufacturing defects and material failure under normal operating conditions, underscoring our confidence in our fabrication quality.

- Q7: How do your products meet environmental sustainability standards?

- A7: We prioritize sustainability by using recyclable materials like HDPE in our Oyster Growth Baskets, which are also UV-stabilized for extended lifespan, reducing the need for frequent replacement. Our manufacturing processes are designed to minimize waste and energy consumption. Furthermore, by facilitating efficient aquaculture, our products support sustainable food production practices that reduce pressure on wild fish stocks and minimize habitat disturbance.

Building Trust: Certifications, Partnerships, and Customer Support

A reputable wire mesh fabricator builds trust through transparent operations, robust certifications, and unwavering customer support. Our commitment is reflected in:

- ISO 9001 Certification: Our Quality Management System ensures consistent product quality, from raw material sourcing to final inspection.

- Long-Standing Industry Presence: With over two decades of experience in wire mesh manufacturing, we have a deep understanding of industry needs and technical challenges.

- Global Partnerships: Collaborations with leading aquaculture research institutions and farms worldwide continuously inform our product development, ensuring our Oyster Growth Baskets remain at the forefront of innovation.

- Dedicated Customer Support: Our team of technical experts and sales professionals provides end-to-end support, from initial consultation and custom design to post-sales assistance and troubleshooting. We offer comprehensive documentation, maintenance guides, and responsive technical support to ensure optimal product performance and customer satisfaction.

- Transparent Delivery & Warranty: We provide clear delivery schedules and back our products with a robust warranty, reflecting our confidence in their durability and performance.

By leveraging advanced manufacturing, stringent quality control, and a customer-centric approach, leading wire mesh fabricators like us empower industries and communities with reliable, high-performance solutions. Our Oyster Growth Baskets exemplify this commitment, offering unparalleled durability and efficiency for sustainable aquaculture.

For further insights into the aquaculture industry's growth and the role of specialized equipment, please refer to: