Understanding filler wire types: A Comprehensive B2B Guide

In the intricate world of modern manufacturing and fabrication, the selection of appropriate welding consumables is paramount to achieving structural integrity, aesthetic quality, and long-term performance. Among these critical components, filler wire types stand out as foundational elements, directly influencing the mechanical properties, corrosion resistance, and overall reliability of welded joints. This guide delves into the diverse classifications, technical specifications, and application nuances of these essential materials, providing B2B decision-makers and technical personnel with the insights needed to optimize their welding processes. Understanding the specific characteristics of each filler wire type is not merely a technical detail; it is a strategic decision that impacts operational efficiency, material costs, and the longevity of engineered structures across various industries, from petrochemical to construction.

The demand for specialized types of filler wire has surged due to advancements in material science and the increasingly stringent requirements of global industries. From high-strength alloys in aerospace to corrosion-resistant solutions for marine applications, the breadth of available options necessitates a deep understanding of their unique attributes. This includes not only their chemical composition but also their metallurgical behavior during and after the welding process. Manufacturers are continuously innovating, introducing new formulations that offer enhanced weldability, improved deposition rates, and superior mechanical properties, all while adhering to global standards like ISO and ANSI. This dynamic landscape requires continuous education and strategic partnerships to leverage the most effective welding solutions for specific project demands.

The Manufacturing Journey: From Raw Material to Precision Filler Wire

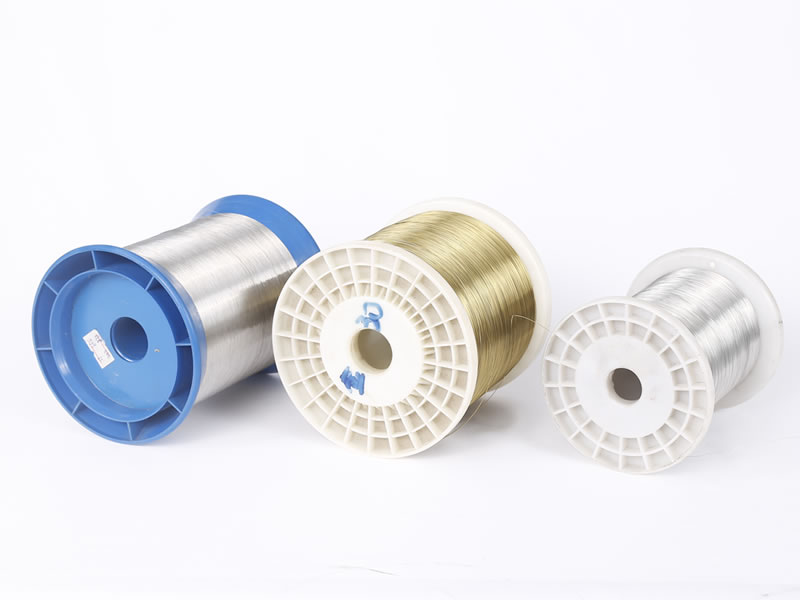

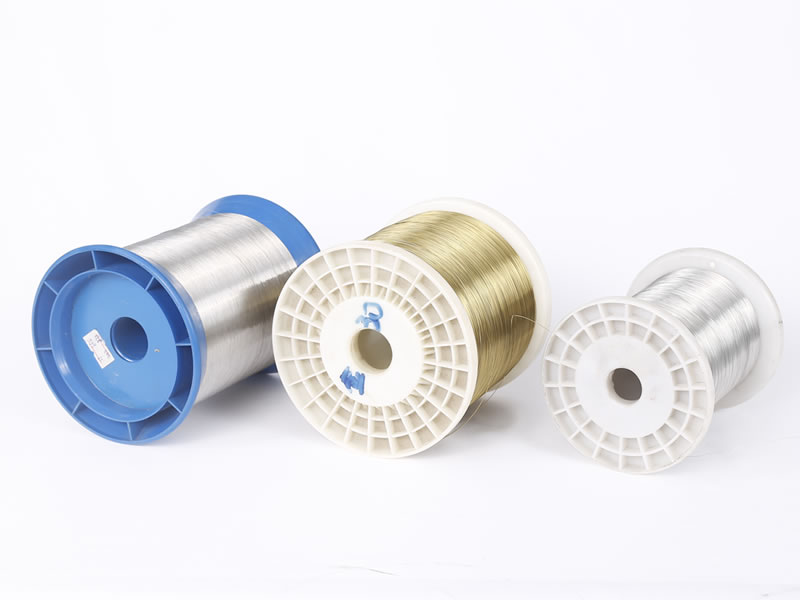

The production of high-quality filler wire types is a meticulous multi-stage process, beginning with carefully selected raw materials and culminating in a precisely engineered product. This journey typically involves casting, rolling, drawing, and often, specialized surface treatments. For instance, common materials like steel, aluminum, and various nickel alloys undergo rigorous preparation to ensure chemical purity and consistent mechanical properties. The initial stage often involves melting raw ingots in electric arc furnaces, followed by continuous casting into billets or rods. This ensures uniform grain structure and minimizes impurities, which are critical for predictable welding performance and defect reduction in final applications, such as in the demanding petrochemical and metallurgy sectors.

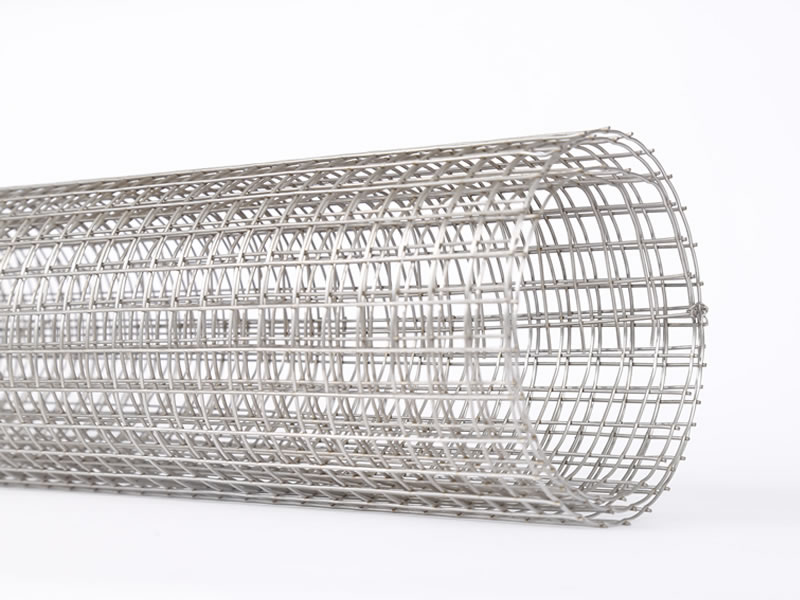

Subsequent to casting, these rods are subjected to hot rolling and then cold drawing processes. Cold drawing progressively reduces the wire's diameter while increasing its tensile strength and improving surface finish. For certain types of filler wire, a copper coating is applied to enhance electrical conductivity, extend shelf life, and improve feedability through welding equipment. This coating also plays a crucial role in arc stability and spatter reduction, contributing to cleaner, more efficient welds. Quality control is integrated at every stage, from material analysis using spectrometry to dimensional checks and mechanical testing of the finished wire. Adherence to international standards such as ISO 14175 and ANSI/AWS A5.01 is non-negotiable, ensuring product consistency and reliability for critical applications, guaranteeing a long service life and exceptional performance in challenging environments.

Key Technical Parameters and Application Scenarios

The diversity of filler wire types is directly linked to their specific technical parameters, which dictate their suitability for different welding processes and base materials. Key parameters include chemical composition (e.g., carbon, manganese, silicon content for steel wires; magnesium, silicon for aluminum wires), tensile strength, yield strength, elongation, and impact toughness. For Gas Tungsten Arc Welding (GTAW or TIG), the selection of types of filler wire for TIG welding is especially critical due to the precise control this process offers. TIG welding requires filler wires that ensure excellent arc stability, minimal spatter, and superior weld bead aesthetics, making purity and surface finish paramount. These characteristics ensure the production of high-quality welds, particularly in applications demanding high aesthetic standards and structural integrity.

Across industries such as oil and gas, shipbuilding, and construction, the appropriate filler wire can lead to significant operational advantages, including energy savings due to optimized deposition rates and enhanced corrosion resistance. For instance, stainless steel filler wires (e.g., ER308L, ER316L) are crucial for environments requiring high resistance to oxidation and corrosion, commonly found in chemical processing plants and food industries. Aluminum filler wires (e.g., ER4043, ER5356) are preferred for lightweight structures in automotive and aerospace, where their excellent strength-to-weight ratio and good electrical conductivity are highly valued. The precise matching of filler wire to the base material and intended application ensures optimal performance, contributing to project success and extended component lifespan.

Comparative Analysis of Common Filler Wire Types

Selecting the right filler wire types involves a thorough comparative analysis, considering factors beyond just material compatibility. Performance metrics like tensile strength, yield strength, elongation, and impact strength at various temperatures are crucial. Below is a comparative table detailing some of the most common types of filler wire used across industries, highlighting their typical compositions and primary applications. This data is derived from extensive industry standards and real-world performance metrics, providing a clear overview for engineers and procurement specialists.

| Filler Wire Type |

AWS Classification |

Primary Composition |

Key Properties |

Typical Applications |

| Carbon Steel |

ER70S-6 |

Mn, Si (deoxidizers) |

Excellent general-purpose, good deoxidation |

Structural steel, automotive, general fabrication |

| Stainless Steel |

ER308L |

19% Cr, 10% Ni (low carbon) |

Corrosion resistance, high temperature stability |

Chemical, food processing, medical equipment |

| Aluminum |

ER4043 |

5% Si |

Low melting point, good fluidity, crack resistance |

Automotive, marine, architectural, general aluminum alloys |

| Nickel Alloy |

ERNiCrMo-3 (Inconel 625) |

Ni, Cr, Mo |

High strength, excellent corrosion resistance at high temps |

Aerospace, chemical processing, power generation |

This table serves as a foundational reference for understanding the material properties and application suitability. For example, while ER70S-6 is versatile for general steel fabrication, its limitations in corrosive or high-temperature environments necessitate the use of specialized alloys like ER308L or ERNiCrMo-3. This strategic selection directly impacts the long-term integrity and performance of the welded assembly. For scenarios requiring high-strength and excellent ductility, particularly with mild and low-alloy steels, filler wires like the Painted Iron Wire, which aligns with robust mechanical performance expectations, are often considered for their foundational strength in structural applications.

Custom Solutions and Manufacturer Expertise

In an era of highly specialized manufacturing, off-the-shelf filler wire types may not always meet the unique demands of complex projects. This is where customized solutions become invaluable. Leading manufacturers, leveraging extensive R&D capabilities, offer bespoke filler wire formulations tailored to specific base materials, welding processes, and performance requirements. This might involve adjusting alloying elements to achieve precise mechanical properties, or applying specialized coatings for improved arc stability or corrosion resistance. Such tailor-made solutions are particularly critical in industries like aerospace, nuclear power, and advanced robotics, where component failure is not an option and adherence to certifications like ISO 9001 and industry-specific standards is paramount.

A key indicator of a reputable manufacturer is their proven track record, demonstrated through long-standing industry partnerships, rigorous quality control, and robust customer support. Companies that invest in advanced testing facilities and hold certifications such as ISO, CE, and sometimes even FDA for specific medical applications, showcase their commitment to quality and authority. Our extensive experience, serving diverse sectors for over two decades, underscores our capability to not only supply standard wire products but also to engineer specific wire solutions that address unique client challenges. Our commitment to excellence is reflected in every product, including our Painted Iron Wire, which embodies our dedication to durability and consistent performance in various industrial applications.

Ensuring Trust and Reliability: FAQs, Warranty, and Support

For B2B buyers, trust is built on transparency, reliability, and robust support systems. When procuring types of filler wire, clarity on product specifications, delivery logistics, and after-sales service is crucial. We provide comprehensive documentation for all our wire products, including material safety data sheets (MSDS) and certificates of analysis, ensuring full compliance and traceability. Our streamlined logistics ensure efficient delivery, typically within 7-14 business days depending on volume and customization, minimizing downtime for our clients. Client testimonials consistently highlight our commitment to timely delivery and the exceptional quality of our wire solutions.

Frequently Asked Questions (FAQs)

Q: What is the typical shelf life of filler wire?

A: Most filler wires, especially those with protective coatings like copper, have a shelf life of 1-2 years when stored in dry, controlled environments. Proper storage is key to preventing oxidation and maintaining weld quality.

Q: How do I select the correct filler wire for my application?

A: Selection depends on the base material, welding process (e.g., MIG, TIG, Submerged Arc), desired mechanical properties of the weld, and environmental conditions. Consulting a material engineer or referring to AWS specifications is recommended. Our technical team is also available for consultations.

Q: Do you offer customized filler wire solutions?

A: Yes, we specialize in providing tailored wire solutions to meet specific client requirements. Our R&D team works closely with customers to develop wires with precise chemical compositions and mechanical properties.

All our wire products, including the robust Painted Iron Wire, come with a standard 12-month warranty against manufacturing defects, underscoring our confidence in their quality and durability. Our dedicated customer support team is available to assist with technical queries, order tracking, and any post-purchase concerns, ensuring a seamless experience from inquiry to application. This comprehensive support framework is a testament to our commitment to long-term client relationships and sustained product performance.

References

- American Welding Society. (2020). AWS A5.01/A5.01M: Specification for Filler Metal Procurement Guidelines.

- International Organization for Standardization. (2019). ISO 14175: Welding consumables – Shielding gases for arc welding and cutting.

- Miller Electric Mfg. LLC. (2021). Welding Filler Metal Selection Guide.

- The Welding Institute (TWI). (2022). Guidance on the selection of filler metals for various welding applications.