Painted iron wire, also known as decorative floral wire or colored metal craft wire, has become a staple in creative industries due to its durability, aesthetic appeal, and adaptability. This article explores the product's features, technical specifications, applications, and the company behind it, Anping Yundong Metal Product Co., Ltd., while incorporating authoritative references to ensure credibility.

Product Overview

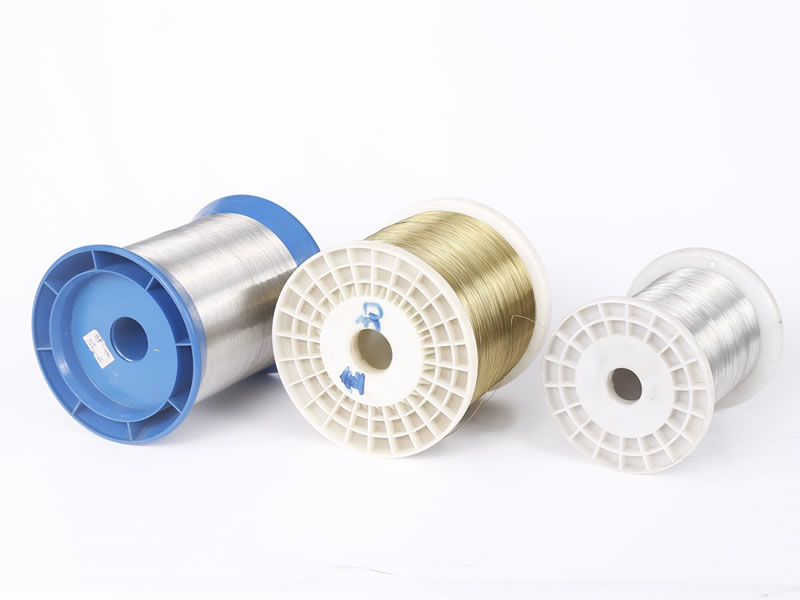

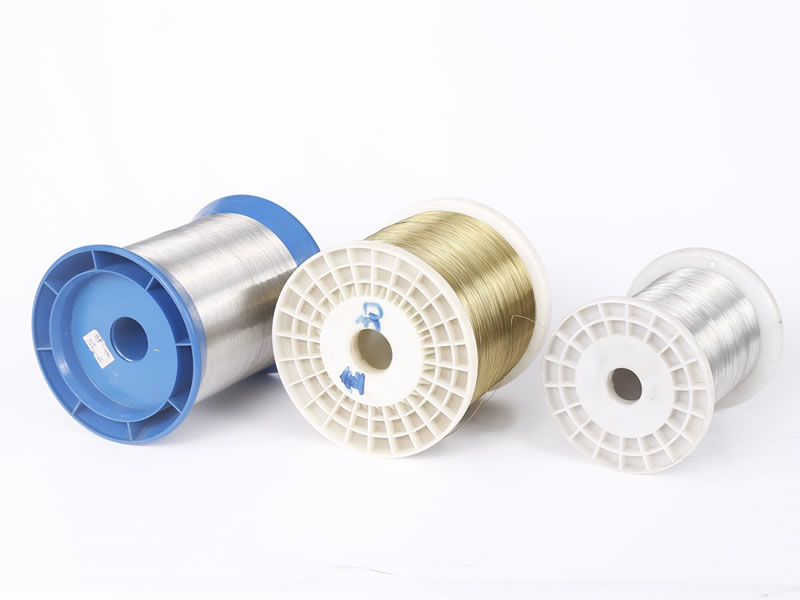

Painted iron wire is a versatile material crafted from various metals, including black wire, galvanized wire, stainless steel wire, and copper wire. Its unique feature lies in the vibrant paint coating, which offers a wide range of colors such as green, black, blue, red, white, gold, silver, purple, yellow, and pink. This product is designed for both functional and decorative purposes, making it a popular choice among artisans, manufacturers, and hobbyists.

Technical Specifications

| Material |

Black wire, galvanized wire, stainless steel wire, copper wire |

| Painted Colors |

Green, black, blue, red, white, gold, silver, purple, yellow, pink, and more |

| Wire Diameter Range |

0.3mm - 1.65mm |

| Section Shape |

Round |

| Features |

Smooth, bright, easy to paint off, flame retardant, environmentally friendly |

| Usage |

Weaving, binding, floral ligation, jewelry line, bookbinding |

| Package |

Plastic spools, wooden sticks, straight-cut bundles |

Key Features and Advantages

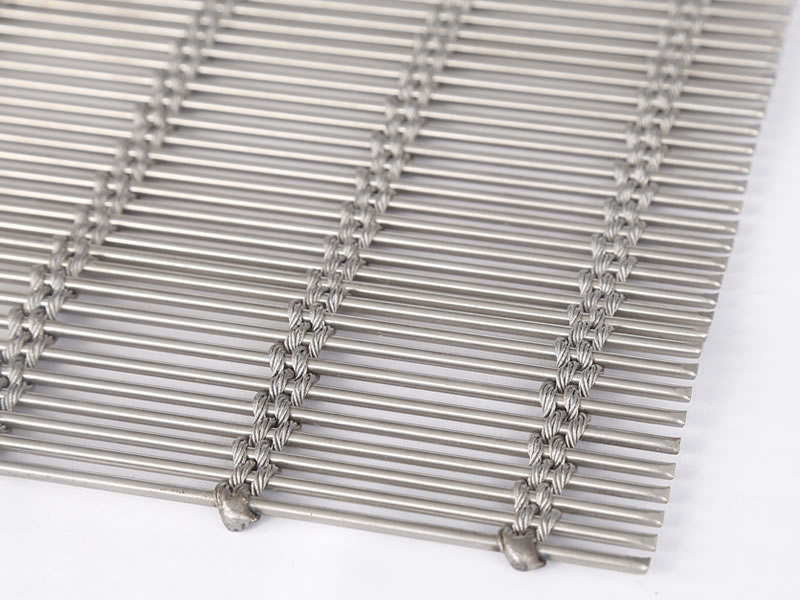

The painting process of this wire ensures a smooth and bright finish, making it ideal for intricate designs. One of its standout features is the ability to retain paint even after bending 180 degrees, eliminating the risk of cracking or peeling. Additionally, the wire is flame retardant, enhancing its safety for use in various environments. Its eco-friendly properties align with modern sustainability standards, appealing to environmentally conscious consumers.

Applications and Use Cases

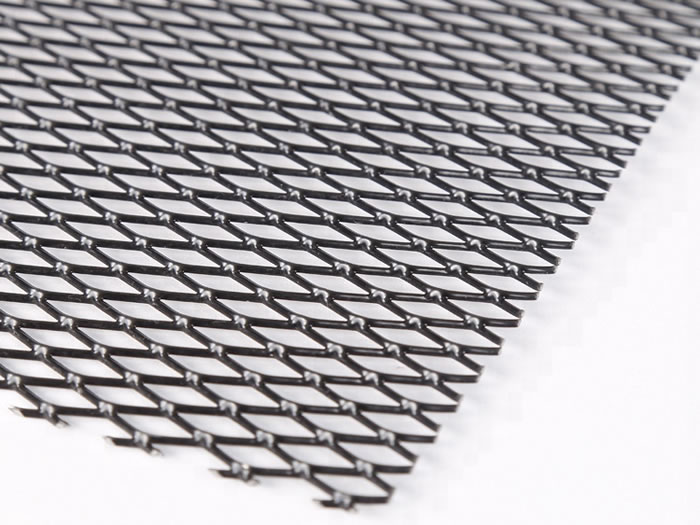

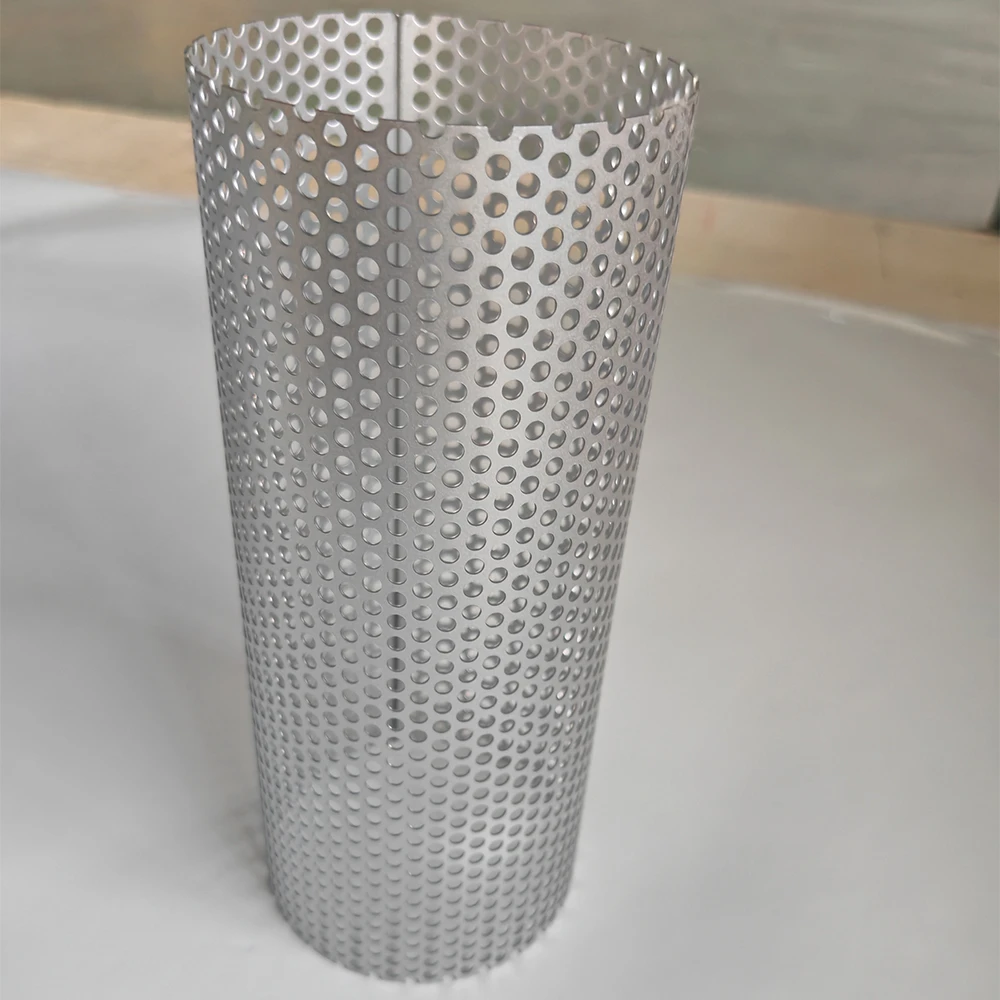

The versatility of painted iron wire is evident in its wide range of applications. In the craft industry, it is used for weaving, binding, and floral ligation, enabling the creation of intricate patterns and structures. For jewelry makers, the wire serves as a durable and colorful material for crafting delicate pieces. In the publishing sector, it is employed for bookbinding, providing a secure and aesthetically pleasing finish. The wire's adaptability extends to industrial settings, where it is used for binding and securing materials in manufacturing processes.

Company Background: Anping Yundong Metal Product Co., Ltd.

Founded in Anping County, Anping Yundong Metal Product Co., Ltd. has established itself as a leading manufacturer of metal products. With a commitment to quality and innovation, the company has become a trusted supplier for painting iron wire and other metal craft materials. Their extensive product range and dedication to customer satisfaction have earned them a reputation for excellence in the industry.

Industry Standards and Authority References

The National Institute of Standards and Technology (NIST) plays a pivotal role in establishing standards for materials and manufacturing processes. While specific references to painted iron wire may not be available, NIST's guidelines on environmental protection and material safety provide a framework for evaluating the eco-friendly and safety aspects of products like painted iron wire. By adhering to these standards, Anping Yundong Metal Product Co., Ltd. ensures their offerings meet rigorous quality and safety benchmarks.

Conclusion

Painted iron wire is a multifaceted material that combines functionality with aesthetic appeal. Its diverse applications, from craft projects to industrial uses, highlight its value in various sectors. With a strong commitment to quality and sustainability, Anping Yundong Metal Product Co., Ltd. continues to lead in providing innovative solutions for metal craft needs. As the demand for eco-friendly and durable materials grows, painted iron wire remains a top choice for creators and manufacturers worldwide.

References

National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov/