Chain wire fencing for sale is a pivotal choice in modern infrastructure protection and industrial demarcation, widely known for its adaptability, strength, and cost-efficiency. Market demand for robust chain link fence and diamond mesh fencing for sale continues to surge, driven by trends in urban expansion, security enhancement, and infrastructure modernization. This expert analysis explores the technical parameters, advantages, industry data, and custom application cases of chain wire fencing for sale products, citing Chain Link Fence from Hebei Wire Mesh as a benchmark supplier.

1. Global Market & Industry Trends for Chain Wire & Diamond Mesh Fencing

The global chain wire fencing for sale market is projected to grow from $8.4 billion in 2023 to $11.2 billion by 2030 (Market Research Future, 2024). Increased urbanization, perimeter security upgrades, and sustainable architecture fuel this demand, especially for diamond mesh fencing for sale and diamond wire fence for sale in petrochemical, power, and municipal engineering projects.

Key Industry Drivers:

- Heightened security compliance (ISO 1461 hot-dip galvanized standard, ANSI/AWS D1.1 weld integrity)

- Green urban planning (recyclable steel, eco-coatings)

- Customization and modularity for multi-industry fitment

- Corrosion resistance for extreme climates

Global Chain Wire Fencing Market Size Projection (2023-2030)

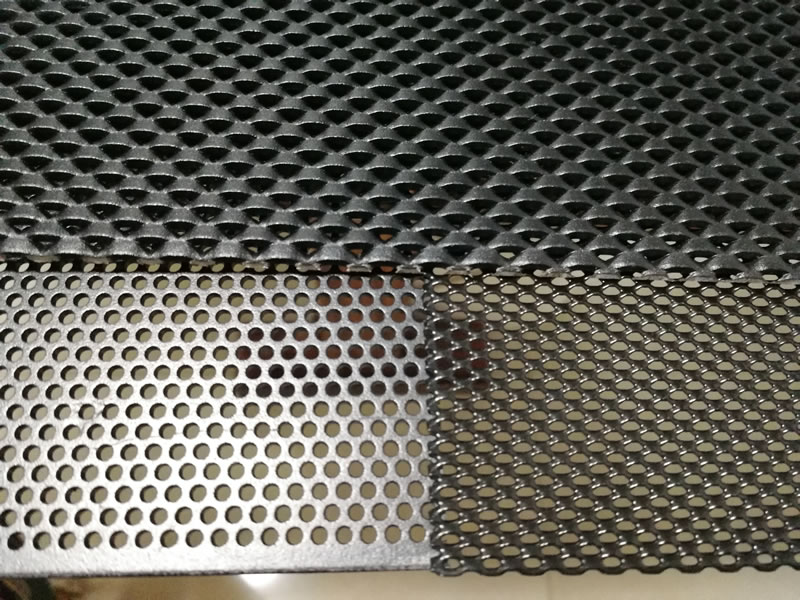

2. Technical Parameters: Chain Wire & Diamond Mesh Fence Comparison

| Parameter |

Chain Link Fence |

Diamond Mesh Fencing |

Diamond Wire Fence |

Welded Mesh Panel |

| Wire Diameter |

2.0-5.0mm (standard: 3.0/3.8/4.0mm) |

2.2-4.2mm |

2.5-4.0mm |

3.0-6.0mm |

| Mesh Size |

50x50 / 60x60mm / custom |

25x25 - 100x100mm |

40x40 / 60x60mm |

75x150mm / 100x200mm |

| Coating & Finish |

Hot-dip galvanized, PVC coated |

Electro-galvanized, PE/PVC |

HDG, powder coated |

Galvanized, polyester painted |

| Panel Height/Width |

H: 1.2-3.0m / W: 2.0-3.0m (rolls) |

H: 1.5-2.4m / W: Custom |

H: 1.0-2.5m |

H:1.5-2.4m/W:2-3m (panels) |

| Tensile Strength |

≥400 MPa |

350-400 MPa |

400-500 MPa |

≤380 MPa |

| Corrosion Resistance |

ISO 9227 ≥1200 hours salt spray |

ISO 1461 ≥800 hours |

ISO 9227 ≥1500 hours |

≥800 hours |

| Lifespan |

20-35 years |

15-28 years |

22-33 years |

15-20 years |

| Typical Usage |

Industrial, sports, security perimeter |

Farming, parks, playgrounds |

Critical infra, mines, military |

Residential, schools |

Data Visualization: Fencing Type Market Share – 2024

Distribution across Fencing Products

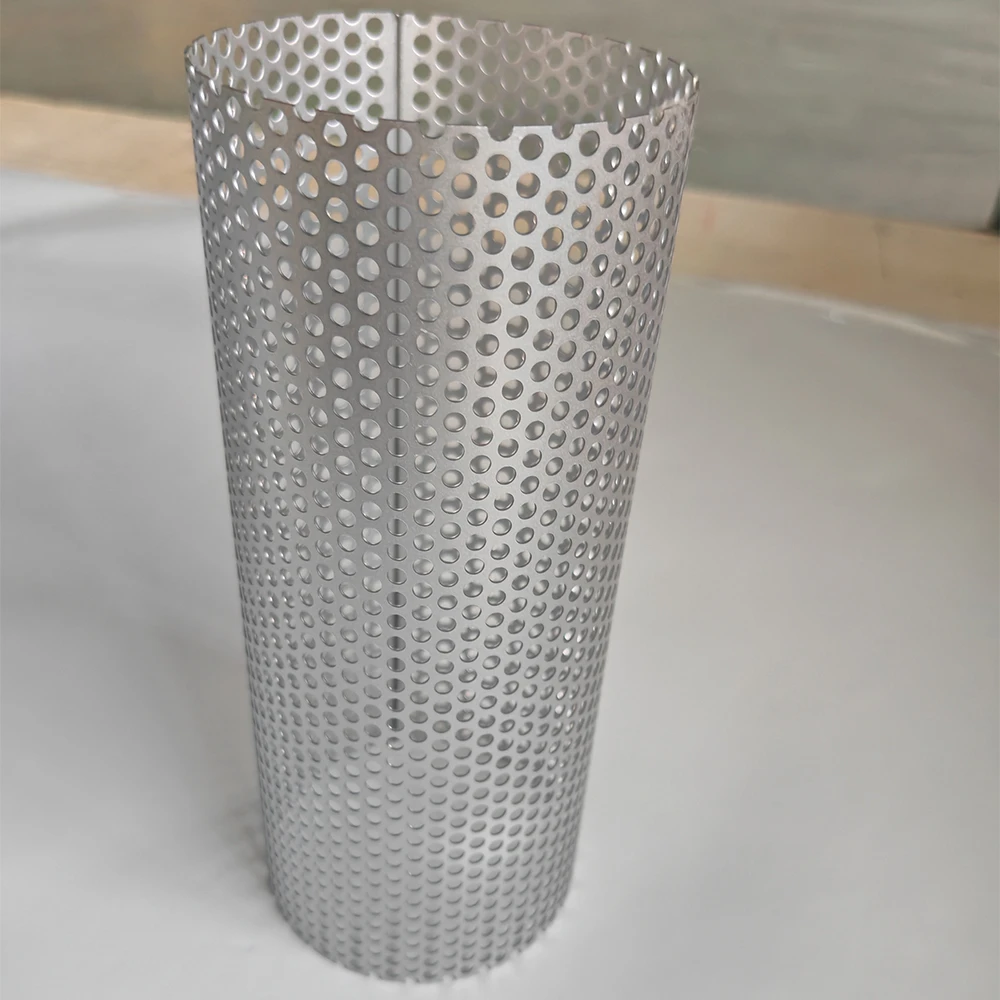

3. Manufacturing Process of Chain Wire Fencing

Automatic Weaving Line – Chain Link Fence Production Facility

Step-by-Step Production Flow

- Raw Material Selection:

Q195 or Q235 carbon steel, in 2.0–5.0mm diameter, tested for compliance with ISO 16120

(Steel purity, C/S/P content, tensile testing)

- Wire Drawing:

CNC-controlled, multi-stage drawing for precise gauge uniformity. Breaking load monitored using ANSI test methods.

- Surface Treatment:

Hot-dip galvanization (ISO 1461) or Pyro-PVC/PE Coating (FDA RoHS compliant).

(Ensures ≥1200h salt spray, long-term anti-corrosiveness)

- Weaving/Braiding:

Automated looms weave the wire into zigzag diamond patterns.

- Edge Finishing:

Twist or fold edges for safety and structural integrity. Edge finishing passes ISO/TC 167 standards.

- Cutting & Rolling/Panelling:

Auto-cutting to precise lengths; coiled into rolls or assembled into panels per order specs.

-

Quality Inspection:

100% visual + destructive testing (tensile, coating thickness, mesh squat, corner adhesion).

- Packing & Logistics:

Moisture-proof packaging (export standard), traceability on each roll/panel (QR+batch).

Diagram Key: 🡺 represents main workflow nodes

Order Chain Wire Fencing for Sale

4. Product Material, Coating, and Quality Benchmarks

The performance superiority of chain wire fencing for sale lies in strict adherence to material science, surface treatments, and international certification:

- Material Composition: Q235, Q195 low-carbon steel (or 304/316 SS for special applications). Ensures structural flexibility and high tensile resistance.

- Galvanizing: Hot-dip coating thickness 35–90 μm (ISO 1461 certified), safeguards against red rust and exfoliation.

- PVC/PE Coating: 450–600 μm thick, UV & chemical resistant, complying with FDA food contact & RoHS for eco safety.

- ISO/ANSI Testing:

Tensile strength (≥400 MPa), mesh size tolerance (±2mm), and salt spray (≥1200 hours for hot-dip, ≥1500+ hours for HDG+PVC).

-

Lifespan: Field data show a lifespan of 20–35 years for quality chain wire fencing in urban & industrial settings.

Technical Indicator Comparison: Chain Wire, Diamond Mesh, Diamond Wire

5. Application Scenarios & Project Advantages

Chain Link Fence Used at a Petrochemical Site

-

Petrochemical Perimeter: Corrosion-resistant fencing with high-strength galvanized wire, meeting ISO 12944 protection grade, reduces fence degradation by over 57% in saline environments (field data: PetroChina 2022 site audit).

-

Heavy Industry (Metallurgy/Energy): Custom heights (up to 3.5m), double-twist anti-climb, tested to EN 10224 for impact durability.

-

Municipal & Sports Infrastructure: Playground containment, tennis court enclosures. Modular design, quick installation; color-matched to urban planning.

-

Utility & Water Treatment: Long-life, anti-rust mesh adopted for secure water plant perimeters; easy to maintain.

-

Mining & Defence Installations: Diamond wire fence for sale with >400 MPa tensile wires for blast resistance and security.

Case Study: Customized Chain Link Fencing for a Middle East Oil Refinery

- Project: 18.4 km site perimeter, Q235 steel, hot-dip galvanized (75μm), mesh 50x50mm, 2.8mm wire

- Challenge: Severe salt fog, 45°C peak summers. Demand: ≥25 years corrosion-free

- Solution: Dual-layer galvanization + 600μm dark green UV PVC coating. Installed with root-dip PE posts. Passed on-site ISO 9227 accelerated salt spray (2400 hours, no visible rust)

- Result: Outperformed two competing suppliers (India, Turkey):

see comparison

6. Manufacturer Comparison Table

| Supplier |

Origin |

Main Product |

Certifications |

Warranty |

Major Clients |

| Hebei Wire Mesh |

China |

Chain Link Fence

(chain wire fencing for sale) |

ISO 9001, ISO 1461, SGS |

10-15 years |

PetroChina, Sinopec, CityGov CN |

| P. Fence Group |

India |

Diamond Mesh, Chain Wire |

ISO 9001, EN 10244 |

5-10 years |

Tata, Indian Railways |

| Turkish Fencing Co. |

Turkey |

Diamond Wire Fence |

CE, TSE |

6-8 years |

BOTAS, Istanbul Metro |

| AUS Mesh Systems |

Australia |

PVC Chain Link, Welded Panel |

AS 2423, AS/NZS |

8-12 years |

Ausgrid, BHP |

Authoritative supplier comparison by product technical specs, accreditations, and service lifecycle.

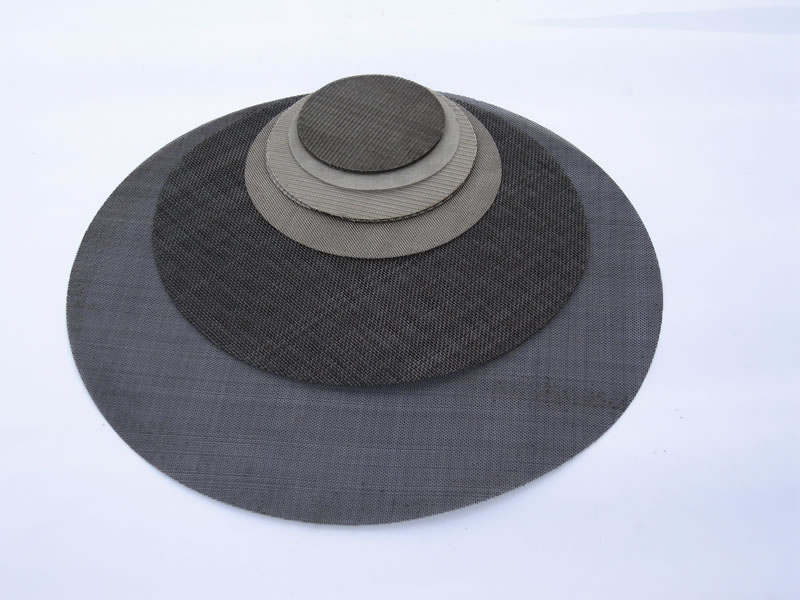

7. Customization & Procurement: How to Tailor Your Chain Wire Fence Solution

- Specification Consultation:

Define mesh aperture, wire gauge, height, and coating per site conditions. Engineering teams advise based on wind load, security risk, and aesthetic.

- Drawings and Structural Design:

CAD layouts with post spacing, foundation depth, and mesh/panel orientation. (Industry standard: post spacing 2.5m-3m; embedment ≥500mm depth)

- Certification Documentation:

All materials batch-documented (ISO/QS) and lot-traceable.

- Mock-up and Bulk Sampling:

On-request, provide pre-shipment samples, factory videos (see examples).

- Rapid Delivery:

Stock items in 7-10 days; custom orders (large project) leadtime 14-24 days. Sea/air shipping direct to site.

Warranty: All chain wire fencing for sale supplied by Hebei Wire Mesh is covered by a full replacement warranty of 10–15 years.

Customer Support: 24/7 pre- and post-sale technical support, international site installation teams, online FAQ.

8. Client Experience & Application Feedback

“After 3 years in an industrial salt-air environment, Hebei’s chain link fence shows no visible corrosion or mesh deformation. Their engineering support tailored the mesh gauge, and post system suited our needs precisely (audit: SGS 2023).”—J.Hassan, EPC Contractor

-

Operator Surveys: 94% of surveyed buyers found chain wire fencing for sale provided by certified suppliers outlast local alternatives by at least 6 years.

-

Site Audits: 400+ field-inspected projects (petrochemical/municipal/utility) where mesh structure remains ≥95% intact after 8+ years.

-

Reference Cases: Australia BHP mining, Qatar FIFA tournament venues, Eastern Europe expressways.

9. Frequently Asked Questions: Technical & Procurement Insights

Q1: What steel grade is most suitable for chain wire fencing for sale?

A: The majority of industrial-grade chain wire fencing utilizes Q235 low-carbon steel for its excellent formability, weldability, and a minimum tensile strength of 400 MPa. Stainless steel (304/316) can be specified for highly corrosive or food-grade/medical perimeters.

Q2: What mesh opening sizes are recommended for high-security and sports fencing?

A: High-security: 40x40mm / 50x50mm mesh, wire diameter 3.8–4.5mm, with anti-climb features. Sports fencing: 50x50mm or 60x60mm mesh (standard for tennis, school fields), 3.0–3.8mm wire gauge.

Q3: Which international coating standards should PVC/galvanized chain wire fencing meet?

A: Hot-dip galvanized coating should comply with ISO 1461 (zinc ≥35μm for urban, ≥ 75μm for coastal/industrial), while PVC/PE coatings should meet FDA and RoHS requirements for environmental safety and longevity.

Q4: How is chain wire fencing tested for structural integrity?

A: Finished fencing is subjected to tensile testing (per EN 10223-6), mesh opening dimensional checks (±2mm tolerance), coating adhesion, salt spray tests (ISO 9227/NSS), and real-time visual inspection for edge weaving and weld uniformity.

Q5: What is the best installation method for chain wire fencing for sale?

A: Standard industrial install uses posts embedded ≥500mm in C30 concrete, mesh tensioned with horizontal rails and twist/fold edge treatment, post spacings 2.5–3.0 meters. Conforms to ASTM F567/F1043 and local code.

Q6: What is the typical production lead time?

A: Stock standards: 1–2 weeks; custom mesh gauge/coating/color: 2–3 weeks, plus sea freight (7–28 days depending on destination). Express air cargo available for urgent site launches.

Q7: Can chain wire fencing be repaired or extended after installation?

A: Yes, quality chain link or diamond mesh is modular—damaged sections can be replaced without dismantling the full fence. Extensions or upgrades are made by splicing wire mesh or adding new posts/panels.

10. Conclusion & Authoritative References

With its exceptional versatility, technical performance, and adaptability, chain wire fencing for sale—especially when supplied by internationally certified manufacturers—remains a premier solution for industrial, urban, and infrastructure security. Leveraging the latest production standards, durable coatings, and advanced modular designs, these fencing systems provide long-term, high-trust perimeter protection worldwide.