Introduction to High-Performance Stainless Steel Baskets in Industrial Applications

In diverse industrial landscapes, the demand for robust, corrosion-resistant, and hygienically superior containment solutions is paramount. The stainless steel basket stands as an indispensable tool, offering unparalleled durability and performance across a spectrum of critical applications. From intricate component cleaning in manufacturing to precise sterilization in medical facilities, these baskets are engineered to withstand harsh environments while ensuring product integrity. Their inherent properties, such as high tensile strength, excellent thermal stability, and resistance to chemical degradation, make them a preferred choice over conventional materials. This article delves into the meticulous engineering, versatile applications, and strategic advantages that define a high-quality stainless steel basket, providing insights crucial for B2B decision-makers and technical procurement specialists. We explore how advanced manufacturing processes, stringent quality control, and a deep understanding of industry-specific needs contribute to the development of baskets that not only meet but exceed operational demands.

The market for stainless steel solutions continues to expand, driven by increasing regulatory compliance in sensitive sectors like food processing and pharmaceuticals, alongside a general trend towards long-term, sustainable industrial investments. A well-designed stainless steel basket, whether it's a specialized component for a production line or a general utility item, directly impacts efficiency, safety, and operational costs. We will detail the specific attributes that contribute to the longevity and effectiveness of these products, including material grades like SS304 and SS316L, which are chosen for their specific resistance profiles. Understanding these foundational elements is key to optimizing procurement strategies and ensuring that the selected baskets align perfectly with the rigorous requirements of modern industrial operations, guaranteeing a superior return on investment through extended service life and reduced maintenance.

The Engineering of Durability: Stainless Steel Basket Manufacturing Process

The manufacturing of a premium stainless steel basket involves a series of precision-engineered steps, starting from the meticulous selection of raw materials to the final quality assurance. The choice of stainless steel grade, typically SS304 or SS316L, is critical and depends on the intended application's corrosive environment, temperature extremes, and hygiene requirements. SS304 offers excellent general corrosion resistance and is widely used for kitchen and general industrial applications, while SS316L, with its added molybdenum content, provides superior resistance to pitting and crevice corrosion, making it ideal for marine, chemical, and pharmaceutical environments. This foundational material decision dictates the basket's long-term performance and durability.

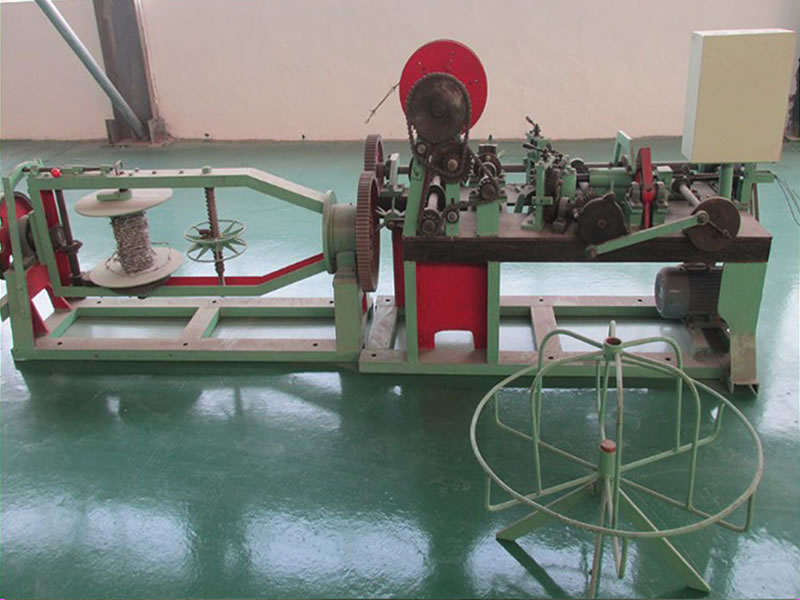

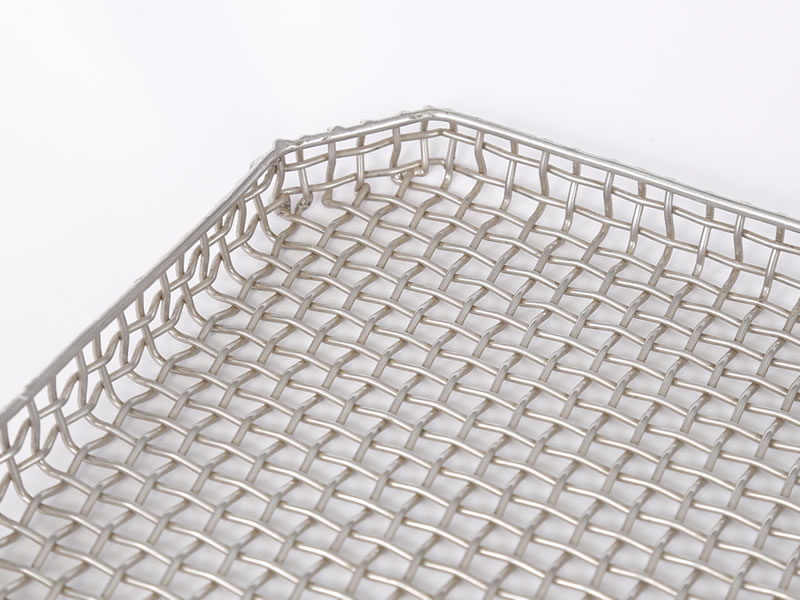

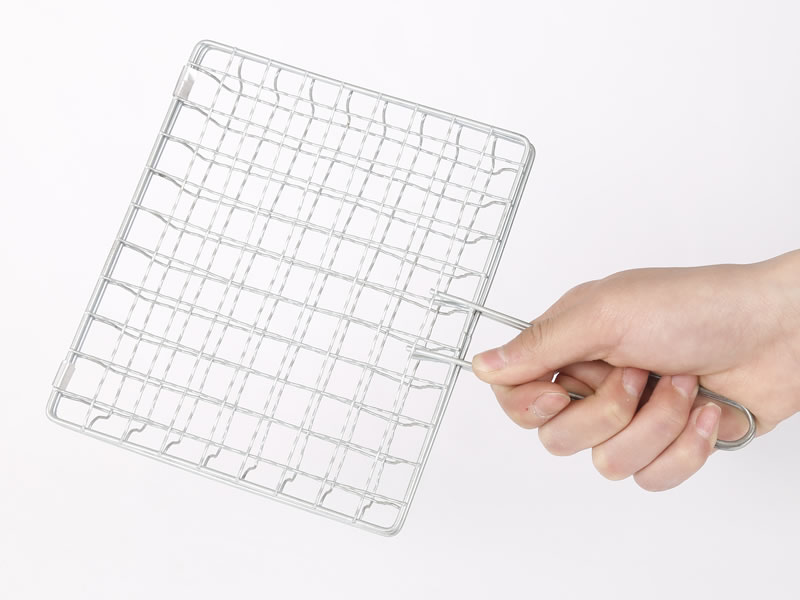

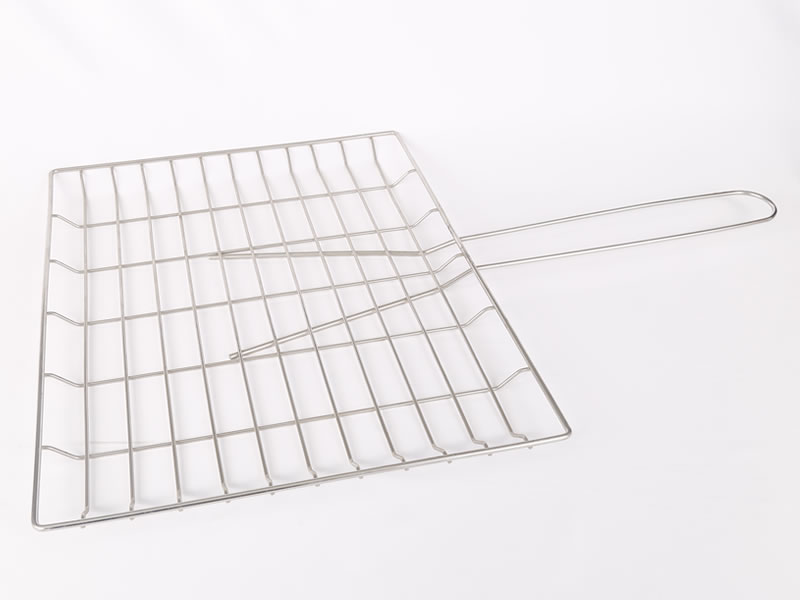

The process flow begins with wire drawing and straightening, where raw stainless steel rods are drawn into precise wire diameters and then meticulously straightened to ensure uniformity. This prepares the material for subsequent shaping operations. Following this, the wires undergo precision cutting and forming. Advanced CNC bending machines are employed to precisely shape individual wires into specific components, such as frames, mesh panels, and handles, adhering to exact dimensional tolerances. The accuracy at this stage is crucial for the overall structural integrity of the final stainless steel basket. Robotic automation often plays a role here, ensuring consistent bends and cuts, which reduces human error and increases production efficiency.

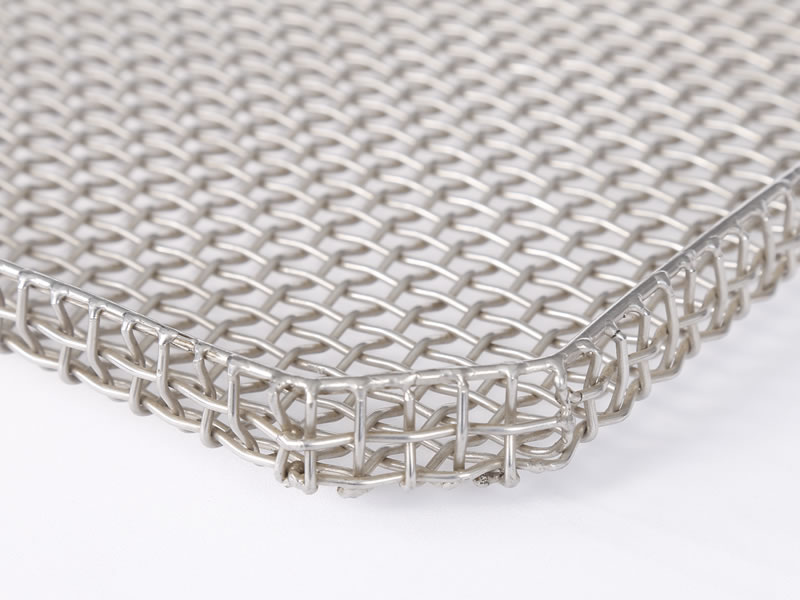

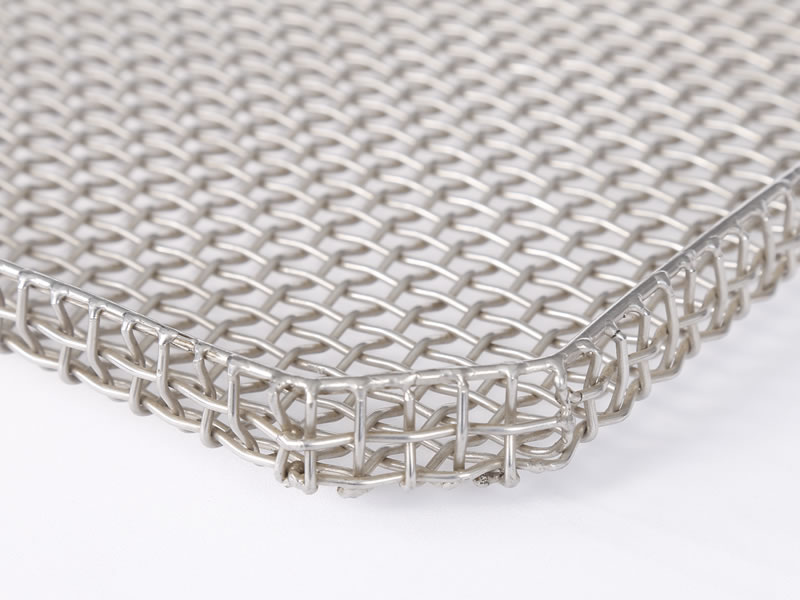

Welding is a critical stage, where individual formed components are joined to create the basket's final structure. Techniques such as TIG (Tungsten Inert Gas) welding and resistance spot welding are commonly utilized. TIG welding is preferred for its ability to produce strong, clean, and aesthetically pleasing welds with minimal distortion, crucial for applications requiring high hygienic standards. Resistance spot welding, on the other hand, offers efficient and robust joining for mesh intersections. Post-welding, the baskets undergo rigorous surface treatment, which includes cleaning to remove any contaminants, pickling to remove heat tint and scale from welding, and passivation. Passivation involves treating the surface with an acid solution to enhance the natural passive layer of chromium oxide, significantly improving the stainless steel basket's corrosion resistance. For highly demanding applications, electropolishing may be applied, which further refines the surface, making it smoother, more hygienic, and extremely resistant to adhesion and corrosion.

Finally, comprehensive quality control and inspection protocols are implemented. This includes visual inspection for defects, dimensional checks against specifications (e.g., ISO 2768 for general tolerances), material composition verification (e.g., using XRF analysis), and tests for weld integrity. For certain applications, load testing or salt spray tests (e.g., ASTM B117) may be performed to simulate harsh operational conditions and ensure the basket's structural integrity and corrosion resistance over its projected service life. Adherence to international standards such as ISO 9001 for quality management and relevant ANSI standards for design specifications ensures that each stainless steel basket meets the highest benchmarks for performance and reliability. The typical service life for a well-maintained industrial stainless steel basket can range from 10 to 20 years, depending on the environment and initial quality.

Key Technical Parameters of Industrial Stainless Steel Baskets

Understanding the critical technical parameters is essential for selecting the optimal stainless steel basket for specific industrial applications. These parameters directly influence the basket's performance, durability, and suitability for its intended environment. Below is a comprehensive table outlining typical specifications that are frequently encountered in industrial and commercial settings, providing a clear reference for procurement specialists and engineers. Each parameter plays a vital role in determining how the basket will interact with its contents and environment, from chemical processes to high-temperature sterilization cycles.

Typical Stainless Steel Basket Technical Specifications

| Parameter |

Description |

Typical Range/Value |

| Material Grade |

Primary alloy used for construction. |

SS304, SS316, SS316L (most common) |

| Wire Diameter (Gauge) |

Thickness of individual stainless steel wires. |

0.5 mm - 5.0 mm (12-24 Gauge) |

| Mesh Aperture (Opening Size) |

Size of the openings in the mesh structure. |

2 mm x 2 mm to 50 mm x 50 mm (or custom) |

| Dimensions (L x W x H) |

Overall external dimensions of the basket. |

Customizable, typically from 150mm up to 1200mm |

| Load Capacity |

Maximum weight the basket can safely hold. |

5 kg - 200 kg+ (depending on design) |

| Temperature Range |

Operating temperature suitability. |

-196°C to +800°C (depending on grade) |

| Surface Finish |

Treatment applied to the surface. |

Electropolished, Passivated, Bright Annealed |

| Welding Method |

Technique used for joining components. |

TIG Welding, Resistance Spot Welding |

| Compliance Standards |

Relevant industry and quality certifications. |

ISO 9001, ASTM, FDA (for food/medical) |

The selection of these parameters is not arbitrary; it is driven by specific application requirements. For instance, in an environment requiring precise filtration or component separation, a finer mesh aperture would be critical. In contrast, for heavy-duty material handling, a larger wire diameter and robust structural design are paramount to ensure high load capacity. The surface finish is particularly important in hygienic applications like food processing or medical sterilization, where electropolishing significantly reduces bacterial adhesion and facilitates easier cleaning, contributing to the overall operational efficiency and safety of the stainless steel basket.

Applications Across Industries: Where Stainless Steel Baskets Excel

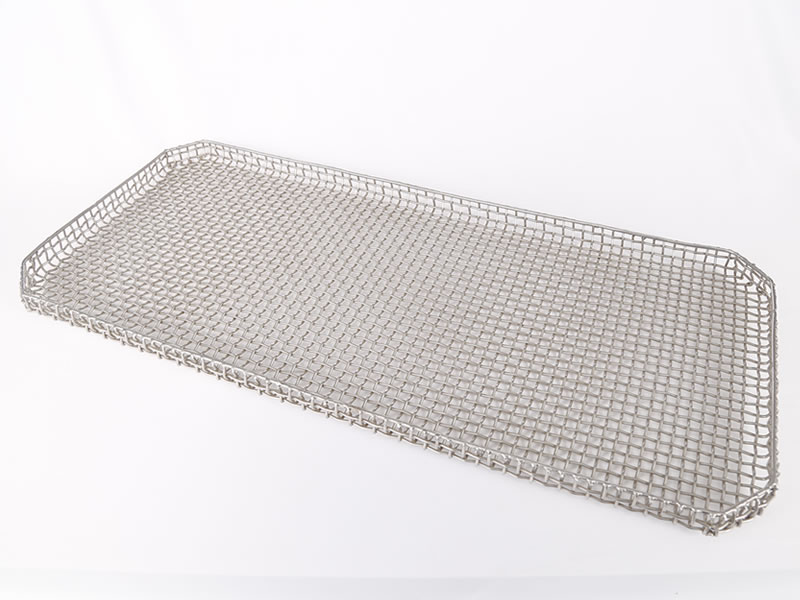

The versatility and inherent advantages of the stainless steel basket make it an essential tool across a multitude of industries, particularly where durability, hygiene, and resistance to harsh conditions are non-negotiable. Its robust construction and chemical inertness allow it to thrive in environments that would rapidly degrade other materials, providing long-term value and operational reliability.

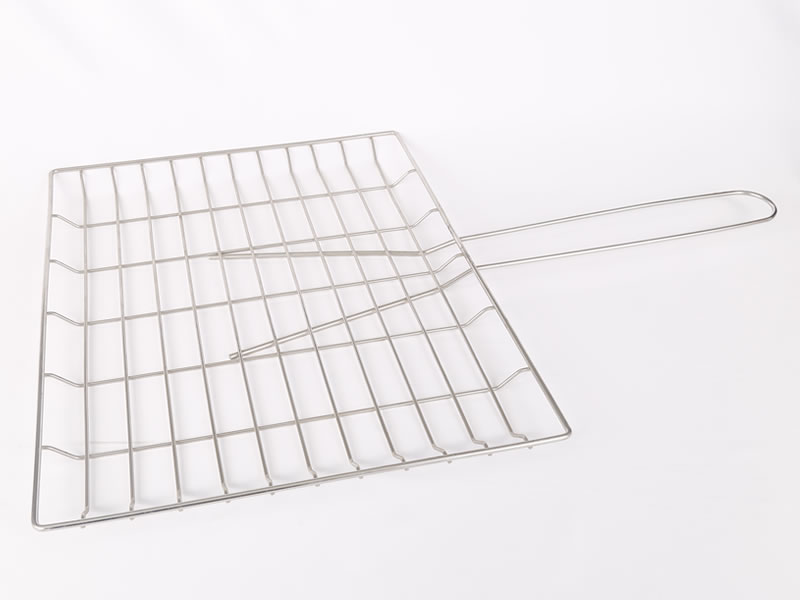

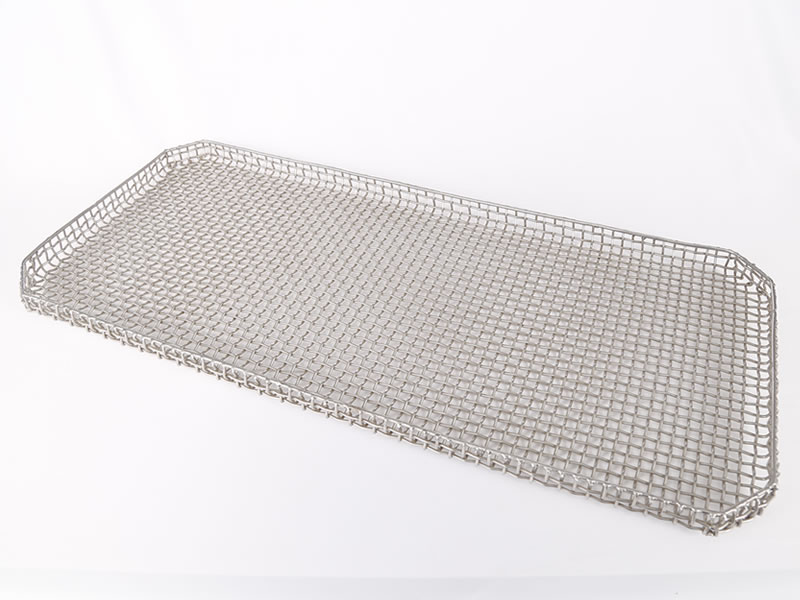

In the Food & Beverage Industry, stainless steel basket kitchen applications are widespread. They are vital for washing, draining, deep-frying, and sterilization processes. Their non-reactive surface prevents contamination and maintains the purity of food products, while their resistance to high temperatures and corrosive cleaning agents ensures longevity even with daily rigorous use. Similarly, in the Medical & Pharmaceutical Industry, these baskets are critical for instrument sterilization (autoclaves), washing, and storage. The ability to withstand repeated sterilization cycles (e.g., steam sterilization at 121°C or dry heat sterilization up to 160°C) without degradation, combined with their non-porous and easy-to-clean surfaces, makes them indispensable for maintaining aseptic conditions and preventing cross-contamination, aligning with stringent FDA and ISO 13485 standards.

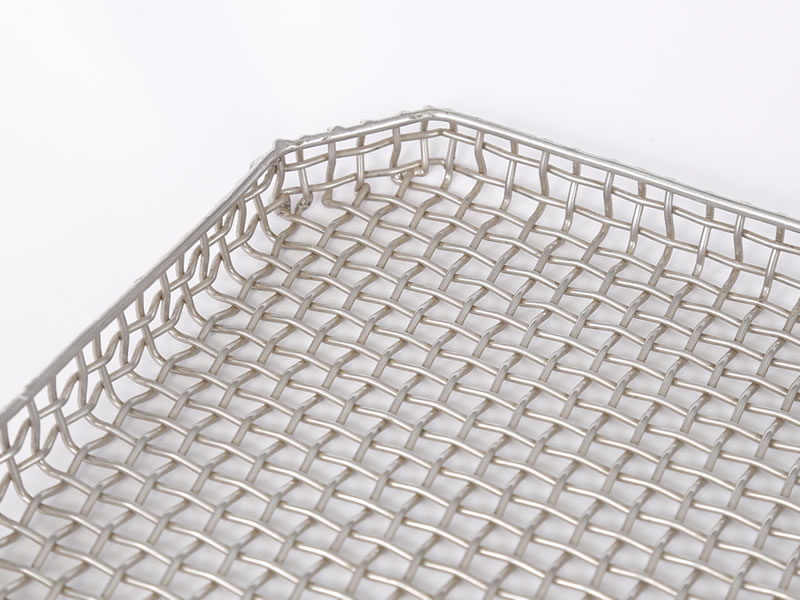

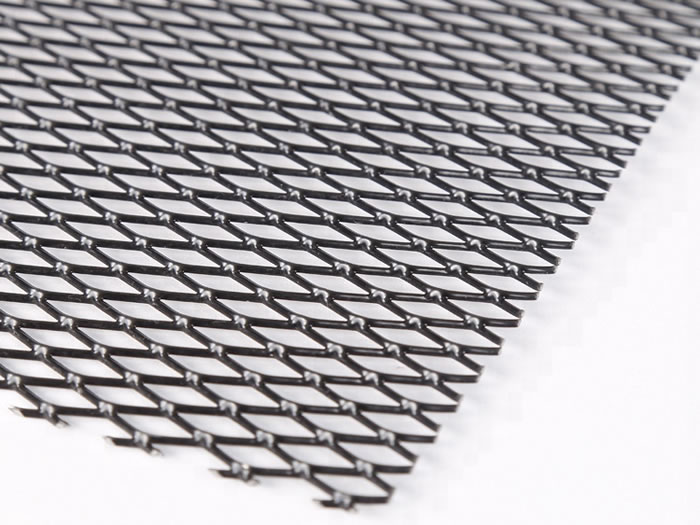

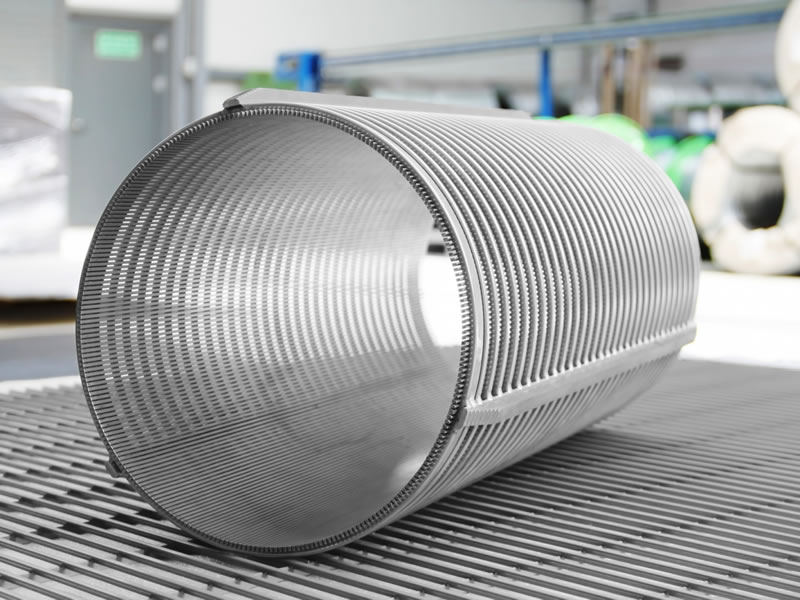

For Industrial Filtration and Parts Cleaning, specifically the stainless steel basket tray designs, these are extensively used in washing machines, ultrasonic cleaners, and degreasing operations. Their robust structure can hold heavy components, while the mesh design allows for efficient liquid flow and debris removal. In Petrochemical and Chemical Processing, the corrosion resistance of SS316L baskets is crucial for handling aggressive chemicals and high temperatures, where they are used for filtration, catalyst support, or component washing within reactors or processing units. Their durability under such extreme conditions significantly reduces downtime and maintenance costs.

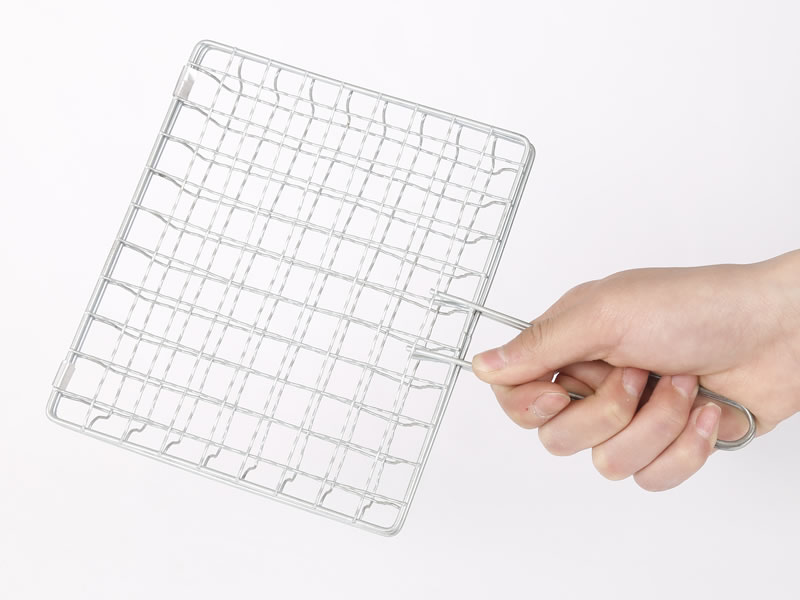

In Laboratories and Research Facilities, specialized stainless steel basket models assist in organizing samples, conducting experiments involving chemicals or heat, and cleaning glassware. Their inertness ensures no reaction with sensitive reagents. Furthermore, in general Manufacturing and Engineering, these baskets are invaluable for material handling, part organization, and facilitating assembly lines. Their resilience minimizes wear and tear, providing a cost-effective solution for long-term operational needs. The ability of stainless steel to maintain structural integrity and aesthetic appeal across such diverse and demanding sectors underscores its superior material properties and the meticulous engineering behind each basket.

Technical Advantages & Performance Beyond the Standard

Beyond basic containment, the technical advantages of a well-engineered stainless steel basket provide significant operational benefits that translate into enhanced efficiency and reduced costs for businesses. Firstly, their superior Corrosion Resistance is paramount. Stainless steel, particularly grades like 304 and 316L, forms a passive chromium oxide layer that naturally resists rust, oxidation, and various chemical attacks. This is crucial in environments exposed to moisture, acids, alkalis, or saline solutions, common in petrochemical, food processing, and medical sterilization. This resistance ensures a longer product lifespan and reduces the need for frequent replacements.

Secondly, their Thermal Stability is exceptional. Stainless steel baskets can withstand extreme temperatures, ranging from cryogenic conditions down to -196°C to high-temperature sterilization processes exceeding 800°C without significant deformation or loss of mechanical properties. This makes them ideal for autoclaving, baking, or applications involving heat treatment. Thirdly, Hygienic Properties and Ease of Cleaning are critical, especially in sensitive industries. The non-porous surface of stainless steel prevents the proliferation of bacteria and accumulation of residues. When combined with electropolishing, the surface becomes even smoother, making cleaning and sanitization remarkably efficient and reducing cross-contamination risks, which is a major advantage for any stainless steel basket used in medical or food-contact applications.

Furthermore, the Exceptional Strength-to-Weight Ratio of stainless steel allows for robust designs that can handle substantial loads while remaining manageable. This structural integrity minimizes bending, warping, and breakage, even under repetitive stress or impact. This contributes directly to a Long Service Life and Cost-Effectiveness, as stainless steel baskets require minimal maintenance and infrequent replacement, offering a superior return on investment compared to alternative materials. Finally, Energy Efficiency can be an understated advantage. In washing, drying, or heating cycles, the open mesh design of a stainless steel basket allows for optimal fluid circulation and heat transfer, reducing process times and energy consumption. This holistic performance profile underscores why stainless steel baskets are a premium, high-value choice for demanding industrial applications.

Customization and Bespoke Solutions for Specific Needs

Recognizing that standard products often fall short of highly specialized industrial requirements, we emphasize our capability in providing bespoke stainless steel basket solutions. Many applications demand unique dimensions, specific mesh configurations, or integrated features to optimize a particular process. Our engineering team collaborates closely with clients to understand their precise operational challenges, component geometries, and environmental conditions. This includes determining the optimal material grade (e.g., SS304, SS316, or even duplex stainless steels for extreme conditions), wire diameter, mesh aperture, and overall structural design to ensure the basket performs flawlessly within its designated system.

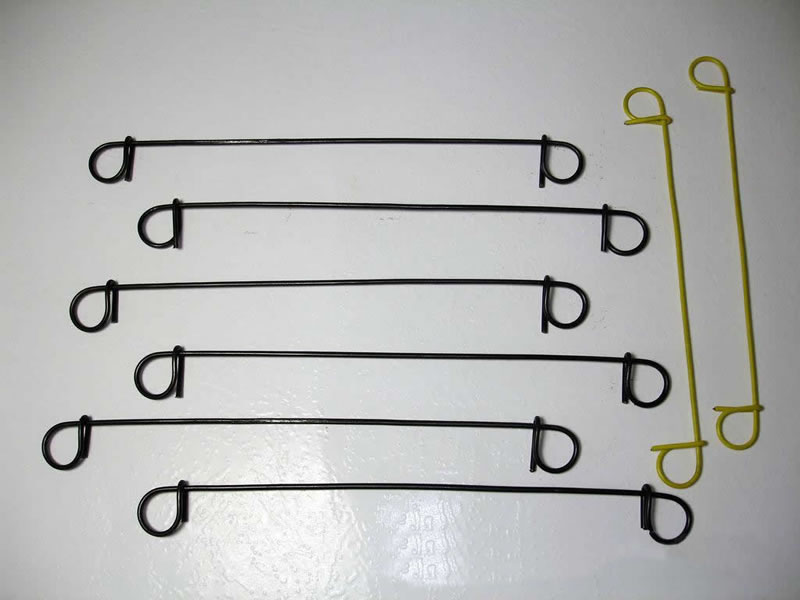

Whether it's a stainless steel basket tray designed for a unique part-washing machine, a deep basket with specialized compartments for medical instruments, or a heavy-duty container111 for material handling in harsh chemical baths, our manufacturing flexibility accommodates these custom demands. We utilize advanced CAD/CAM software for design and simulation, allowing for rapid prototyping and validation of designs before full-scale production. This meticulous approach ensures that each customized stainless steel basket perfectly integrates into the client's workflow, enhancing efficiency, improving safety, and significantly extending the lifespan of the equipment it complements. Our expertise extends to incorporating features such as specialized handles, stacking frames, dividers, lids, or custom mounting brackets, all tailored to the specific operational needs.

Ensuring Quality & Trust: Our Commitment to Excellence ()

Our unwavering commitment to quality is the cornerstone of our operations, ensuring every stainless steel basket we produce meets the highest standards of reliability and performance. We hold ISO 9001:2015 certification, signifying our adherence to rigorous quality management systems across all stages of manufacturing, from raw material sourcing to final inspection and delivery. This certification is a testament to our structured processes and continuous improvement initiatives.

Our internal Testing Protocols are comprehensive, including material composition verification using X-ray fluorescence (XRF) spectroscopy to confirm alloy grade, dimensional accuracy checks using precision measuring tools, and weld integrity assessments through visual and penetrant testing. For specific applications, we conduct load-bearing tests to validate the structural capacity of the stainless steel basket and corrosion resistance tests like salt spray testing (e.g., ASTM B117) to ensure long-term durability in corrosive environments. Our long-standing presence in the wire mesh industry, spanning over two decades, is a testament to our Expertise and Experience. We have successfully completed hundreds of complex projects for global clients in diverse sectors, including major players in the food processing, medical device, and petrochemical industries.

Our clients consistently praise our product quality and responsive service. For instance, a major medical device manufacturer reported a 30% increase in instrument longevity after switching to our electropolished stainless steel basket for their sterilization cycles, citing reduced scratching and improved cleanliness. Similarly, a petrochemical firm noted a significant reduction in basket replacement costs due to the superior corrosion resistance of our SS316L baskets in their chemical washing processes. These direct client experiences underscore our product's real-world Authoritativeness and the tangible benefits it delivers. We believe that Trustworthiness is built not just on product quality, but also on transparent communication, reliable delivery, and steadfast post-sales support, ensuring a seamless experience from inquiry to long-term usage.

Manufacturer Comparison: What Sets Us Apart

In a competitive market, discerning what truly differentiates a manufacturer of stainless steel basket products is crucial. While many suppliers exist, our unique value proposition lies in a combination of unparalleled material expertise, advanced manufacturing capabilities, and a customer-centric approach that ensures superior product performance and service.

Firstly, our Material Sourcing and Certification protocols are exceptionally stringent. We procure raw stainless steel only from certified mills, ensuring that every batch meets specific chemical compositions and mechanical properties required for demanding industrial use. This eliminates the risk of using substandard alloys that might compromise the performance and longevity of the final stainless steel basket, a common pitfall with less scrupulous suppliers. Secondly, our Precision Engineering and Automated Processes set us apart. Unlike manufacturers relying heavily on manual labor, our integration of CNC wire bending, robotic welding, and automated surface treatment ensures consistent product quality, tighter tolerances, and higher production efficiency. This leads to baskets with superior weld integrity, accurate dimensions, and a pristine finish, critical for high-stakes applications.

Furthermore, our dedication to Customer Collaboration and Customization is a key differentiator. We don't just sell standard products; we partner with clients to develop tailored solutions. Our engineering team provides comprehensive consultation, from initial concept to final design, ensuring that the customized stainless steel basket perfectly aligns with unique operational challenges and integrates seamlessly into existing workflows. This proactive approach minimizes design flaws and optimizes performance. Finally, our robust Post-Sales Support and Warranty demonstrate our confidence in our products and commitment to long-term client satisfaction. We stand behind every basket, offering clear warranty terms and responsive technical support, ensuring that our clients receive not just a product, but a reliable solution backed by a trusted partner.

Frequently Asked Questions (FAQ)

Q1: What are the primary differences between SS304 and SS316L stainless steel for baskets?

SS304 is a widely used general-purpose stainless steel, offering good corrosion resistance and is suitable for most applications, including general industrial and kitchen use. SS316L, however, contains molybdenum, which significantly enhances its resistance to pitting and crevice corrosion, particularly in chloride-rich environments like saltwater or certain chemical processing applications. It also has a lower carbon content, making it better for welding and reducing the risk of sensitization.

Q2: How do I determine the correct mesh aperture for my application?

The appropriate mesh aperture for a stainless steel basket depends on the size of the items being contained or processed, and the required flow-through for liquids or gases. For very small components or fine filtration, a smaller aperture (e.g., 2mm x 2mm) is needed. For larger items or when maximum flow is critical (e.g., in a washing process), a larger aperture might be more suitable. Our technical team can assist in selecting the optimal mesh size based on your specific requirements.

Q3: What kind of load capacity can a typical stainless steel basket handle?

The load capacity of a stainless steel basket varies significantly based on its design, wire diameter, and overall dimensions. Standard utility baskets can typically handle 5-20 kg. Heavy-duty industrial baskets, with thicker wires and reinforced frames, can be designed to safely hold 100 kg or more. It is crucial to specify your required load capacity during the inquiry phase so we can design and engineer a basket that meets your exact structural integrity needs.

Q4: Are your stainless steel baskets suitable for high-temperature sterilization?

Yes, our stainless steel basket products are highly suitable for high-temperature sterilization processes, including steam autoclaving (typically up to 134°C) and dry heat sterilization (up to 180°C or higher for some grades). Stainless steel maintains its structural integrity and corrosion resistance exceptionally well at elevated temperatures, making it ideal for medical, pharmaceutical, and laboratory applications that require stringent sanitation.

Q5: What is your typical delivery lead time for custom orders?

Delivery lead times for custom stainless steel basket orders depend on the complexity of the design, order volume, and current production schedule. Generally, for bespoke solutions, the design and prototyping phase can take 1-2 weeks, followed by a manufacturing period of 3-6 weeks. We provide an estimated delivery timeline upon confirmation of your order and strive to meet deadlines efficiently without compromising quality. We also offer expedited options for urgent requirements.

Procurement & Support: Delivery, Warranty, and After-Sales Service

Our commitment to our clients extends beyond the manufacturing of a high-quality stainless steel basket. We understand that efficient procurement, timely delivery, and reliable post-sales support are integral to a successful partnership in the B2B sector.

Delivery: We operate with a streamlined logistics process to ensure efficient and reliable delivery of your orders. For standard products, typical lead times range from 2-4 weeks. For custom or bulk orders, specific timelines will be provided upon quotation, tailored to the complexity and volume of the project. We utilize reputable freight partners to ensure secure and timely shipment, with options for various incoterms (e.g., FOB, CIF, DDU) to best suit your logistical preferences. Our team provides regular updates on shipment status, ensuring transparency throughout the delivery process for every stainless steel basket order.

Warranty: Every stainless steel basket we produce is backed by a comprehensive warranty, typically covering manufacturing defects and material integrity for a period of 12-24 months from the date of purchase. This warranty reflects our confidence in the durability and craftsmanship of our products. In the rare event of a defect arising from our manufacturing process or materials, we commit to prompt repair or replacement, ensuring minimal disruption to your operations. Detailed warranty terms and conditions are provided with each quotation and order confirmation.

Customer Support: Our dedicated customer support team is available to assist with any inquiries, technical questions, or after-sales service needs. From initial consultation and custom design support to troubleshooting and maintenance advice, we provide expert assistance. We believe that exceptional support is key to building long-term relationships, ensuring that your stainless steel basket solutions continue to perform optimally throughout their impressive service life. You can reach our support team via phone or email during business hours, and we aim to respond to all inquiries within 24 hours.

References

- American Society for Testing and Materials (ASTM) International Standards.

- International Organization for Standardization (ISO) 9001:2015 Quality Management Systems.

- U.S. Food and Drug Administration (FDA) Regulations for Materials in Contact with Food and Medical Devices.

- ASM Handbook, Vol. 13A, Corrosion: Fundamentals, Testing, and Protection.

- Journal of Materials Processing Technology.