Trusted Global Supplier

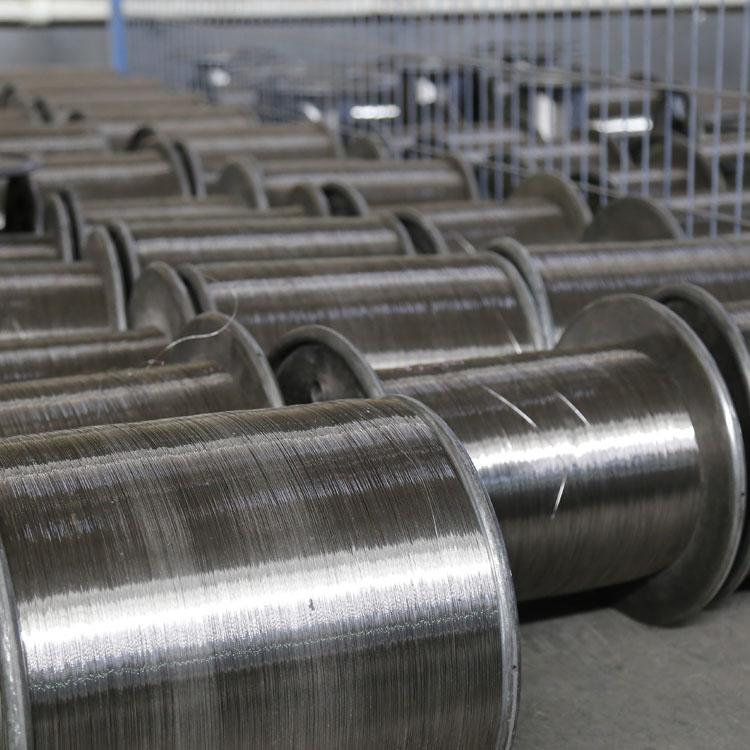

ANPING YUANDONG METAL PRODUCT CO.,LTD. has been a leading manufacturer and global exporter of premium stainless steel wires since 2002. With ISO 9001 certification and manufacturing facilities spanning 50,000 square meters in Hebei, China, we supply high-performance stainless steel wire solutions to industrial clients across 87 countries.

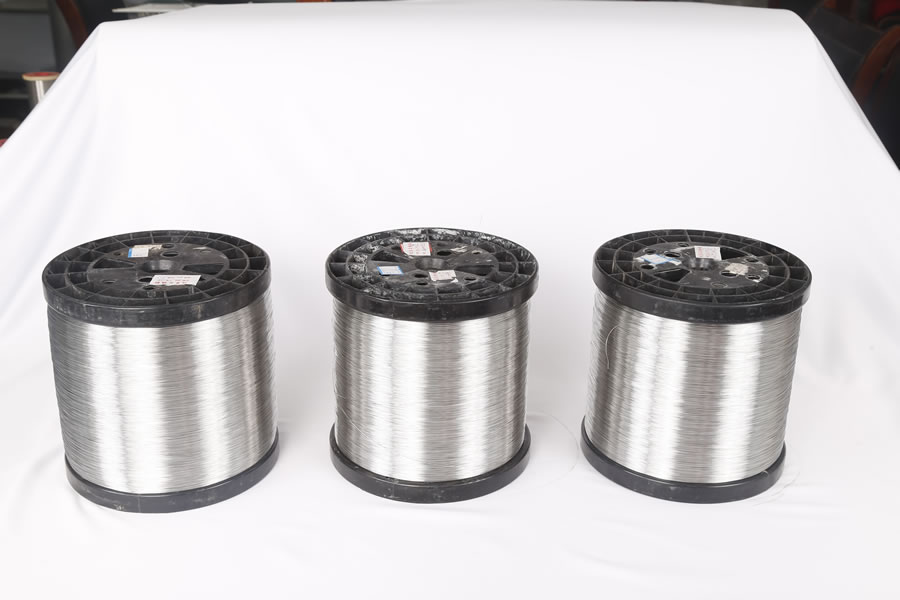

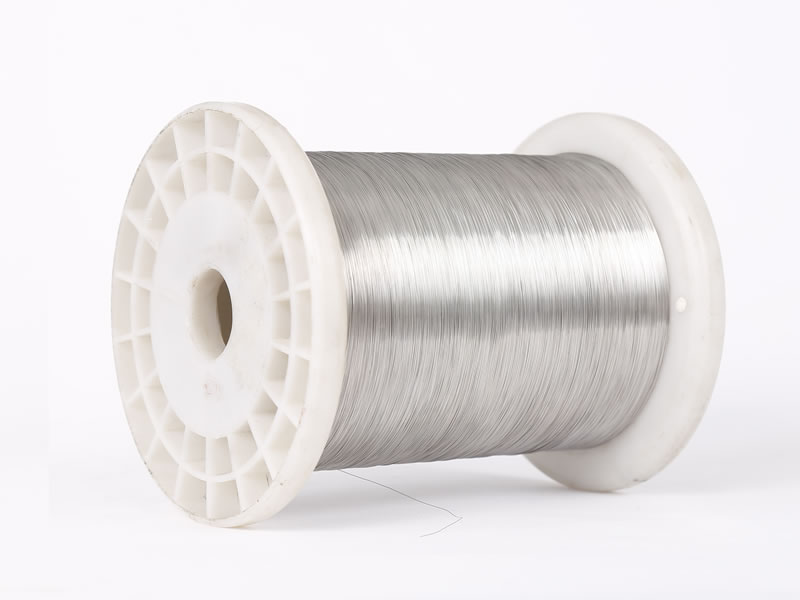

Premium Stainless Steel Wire

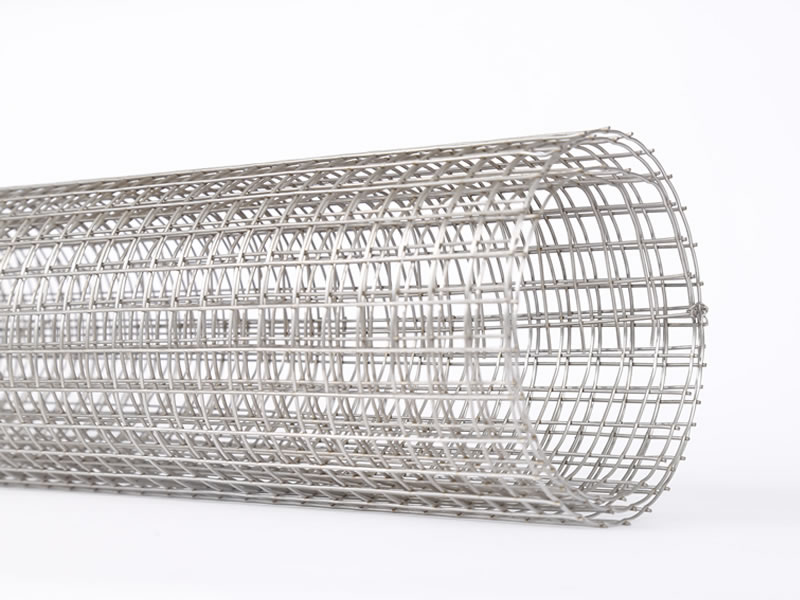

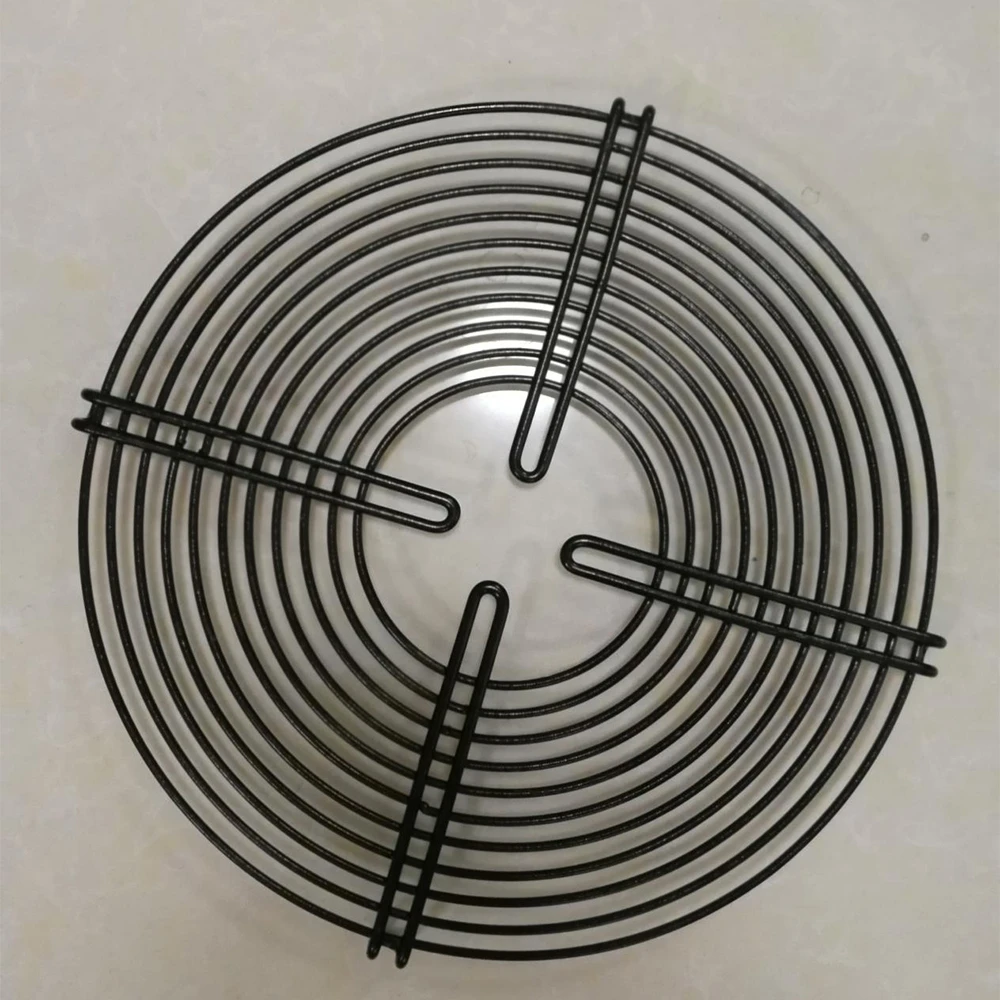

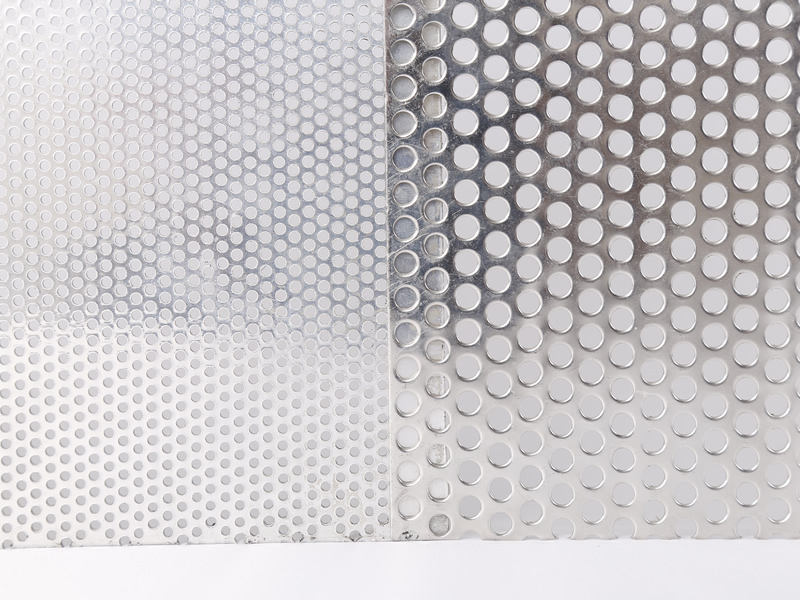

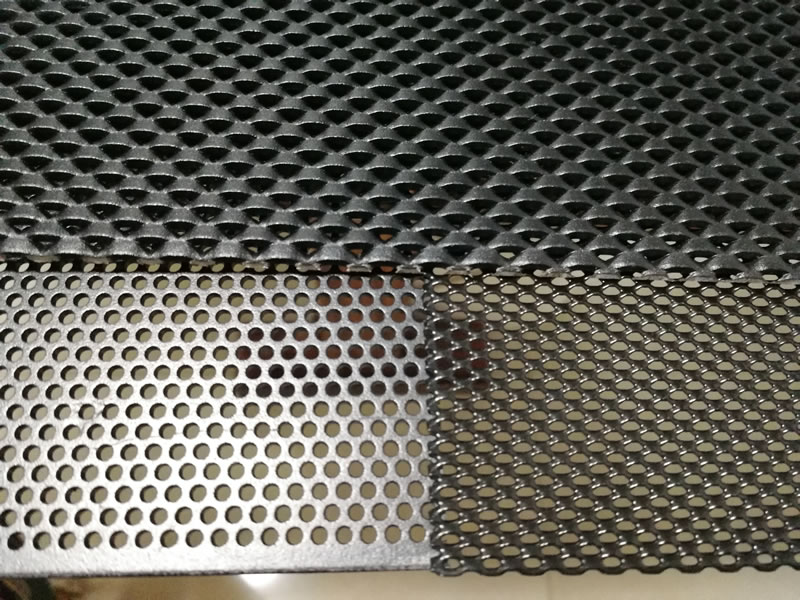

Our flagship product is engineered to meet the most demanding industrial applications with precision and reliability. Manufactured using advanced cold-drawing technology under controlled atmospheric conditions, our wires offer unmatched performance characteristics.

Material: 304, 304L, 316, 316L, 310S, 430 stainless steel grades

Feature: Superior corrosion resistance, exceptional tensile strength (1,500-2,100 MPa), excellent surface finish, precise dimensional tolerance (±0.01mm), uniform mechanical properties throughout the coil

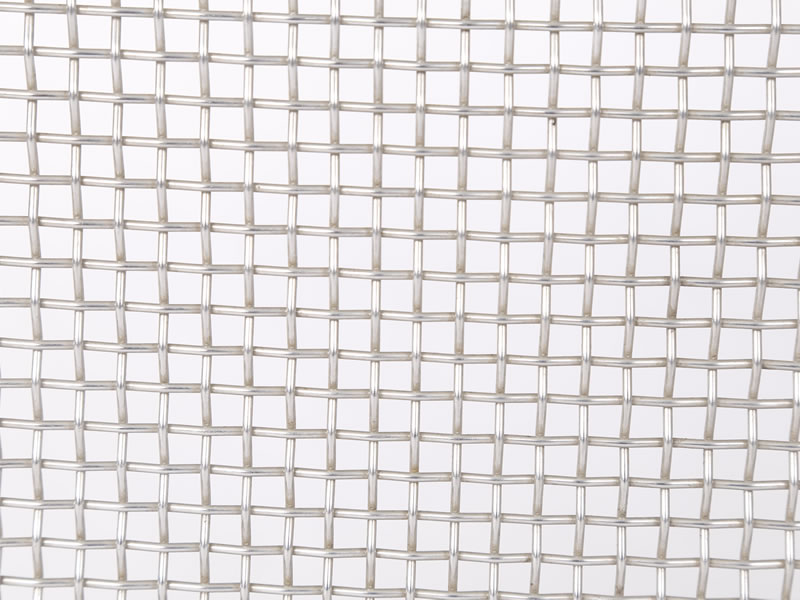

Application: Industrial filtration systems, architectural mesh, automotive components, marine hardware, chemical processing equipment, food processing machinery, medical instruments, and construction reinforcement

Standard Specifications: ASTM A580, ASTM A313, EN 10270-3, JIS G4309, DIN 17440

Industry Trends in Stainless Steel Wire Market

The global stainless steel wire wholesale market is projected to reach $23.8 billion by 2028, growing at a CAGR of 6.2% from 2023-2028. This growth is primarily driven by increasing demand from construction (32% market share), automotive manufacturing (28%), and industrial filtration (18%). With rising environmental regulations worldwide, there's a significant shift toward corrosion-resistant materials like 316L marine-grade stainless steel, which has seen 12% annual demand growth since 2020. The steel wire wholesale segment specifically benefits from infrastructure development projects in emerging economies, particularly in Southeast Asia and Africa.

Technological advancements have transformed stainless steel wire manufacturing, particularly in cold-drawing precision and surface treatment. Modern production facilities now achieve dimensional tolerances within ±0.005mm through multi-stage drawing processes. Additionally, the development of specialized coatings such as PTFE (polytetrafluoroethylene) and PVC has expanded application possibilities for stainless steel mig wire for sale in aggressive chemical environments. These coatings improve corrosion resistance while reducing friction coefficients by up to 40%, significantly enhancing performance in dynamic applications.

Technical Specifications Overview

Selecting the appropriate stainless steel wire requires understanding critical technical parameters that impact performance. The tensile strength of stainless steel wires varies significantly based on grade and tempering process. For example, Type 302 achieves tensile strength of 1,860-2,070 MPa when full-hard tempered, while annealed 304 maintains 620-870 MPa. Surface finish plays a crucial role in corrosion resistance, measured by Ra (Roughness Average) values typically between 0.05-0.20μm for industrial applications. Diameter consistency across lengths is vital, with premium stainless steel wire wholesale products maintaining ±0.01mm tolerance even on diameters of 0.10mm.

Technical Expertise: FAQ

Q1: What determines the corrosion resistance of stainless steel wire?

Corrosion resistance primarily depends on the chromium content (minimum 10.5%) and presence of alloying elements. The chromium forms a passive oxide layer that protects against oxidation. Grades like 316L contain molybdenum (2-3%) which enhances resistance to chlorides and acidic environments. The PREN (Pitting Resistance Equivalent Number) calculated as %Cr + 3.3×%Mo + 16×%N determines pitting corrosion resistance - standard grades typically have PREN 18-25, while 316L has PREN >26.

Q2: How do wire diameter tolerances impact manufacturing processes?

Tolerances significantly affect downstream processing capabilities. Precision ±0.005mm tolerance wire ensures consistent weaving patterns for meshes, maintaining aperture accuracy. In spring manufacturing, tolerance directly affects spring constant consistency. High-precision wire reduces tool wear in CNC coilers by 15-20% and improves production yields by 5-8% compared to commercial tolerance (±0.03mm) wires in automated assembly applications.

Q3: What distinguishes MIG welding wire for stainless steel?

Stainless steel MIG wire for sale features specific alloy compositions optimized for welding characteristics. ER308L contains silicon (0.3-0.6%) and manganese (1.0-2.5%) for improved arc stability and wetting action. Surface finish (Ra 0.15-0.25μm) and minimal lubrication ensure smooth feeding through welding guns. Copper plating is often applied to prevent corrosion during storage without affecting weld pool chemistry. These wires typically come in 0.8-1.2mm diameters with ±0.02mm tolerance.

Q4: What standards apply to architectural stainless steel cables?

Architectural wire rope must comply with ASTM A492 (Stainless Steel Rope Wire) with additional aesthetic requirements. Type 316 (marine grade) is mandated in coastal environments with >100ppm chloride. International Building Code (IBC) requires 3x design safety factors for structural elements. DIN EN 1993-1-11 specifies fatigue requirements for dynamic installations. Surface finishes must maintain Ra ≤0.25μm to minimize corrosion initiation points, typically achieved through precision cold drawing.

Q5: How does annealing temperature affect wire properties?

Annealing relieves cold-working stresses and restores ductility. For austenitic grades (300-series), optimal annealing occurs at 1010-1120°C followed by rapid quenching to prevent chromium carbide precipitation. Full annealing reduces tensile strength by 35-50% but increases elongation by 300-500%. Critical annealing temperatures include: Recrystallization begins at 650-700°C, carbide dissolution above 900°C, and grain growth acceleration beyond 1050°C. Controlled atmosphere annealing prevents surface scaling and maintains corrosion resistance.

Q6: What determines fatigue life in stainless steel springs?

Spring fatigue life depends on surface finish, inclusions content, and residual stresses. Mirror-polished wire (Ra

Q7: What packaging protects stainless steel wire during transit?

VCI (Volatile Corrosion Inhibitor) packaging is standard for international shipments. Wrapped coils first receive anti-tarnish paper coating, then VCI-impregnated polyethylene wrapping. Desiccant bags maintain