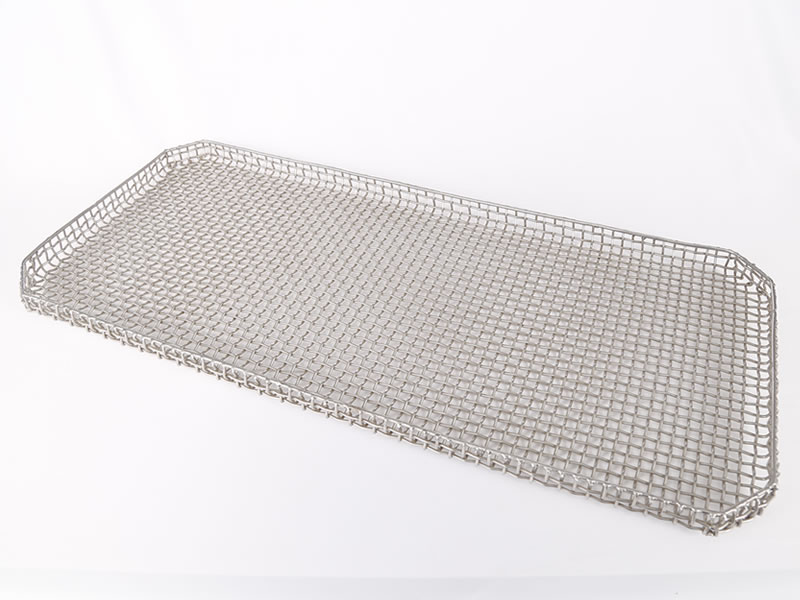

The stainless steel basket is a vital component across numerous industries and applications, renowned for its durability, corrosion resistance, and versatility. Whether applied in the kitchen, industrial processing, or specialized filtration systems, stainless steel baskets offer superior performance and a long service life. In this in-depth article, we analyze the latest industry trends, technical parameters, comprehensive factory comparisons, and real-world application scenarios of stainless steel baskets—including kitchen and tray variants—to provide procurement and engineering professionals with actionable intelligence.

View Full Product Specs

Industry Trends: The Rise of Stainless Steel Basket Solutions in Global Markets

Market research reveals that the global demand for stainless steel baskets is expected to grow at a CAGR of 6.5% from 2023 to 2030 (Grand View Research). Rapid industrialization, food safety awareness, the push for efficient storage solutions, and strict international standards such as ISO 9001 and FDA CFR 21 compliance are primary factors driving this surge.

Stainless steel basket kitchen products in particular enjoy strong demand, as the food & beverage sector moves away from plastics toward lifetime, eco-friendly alternatives.

Manufacturing Process of Stainless Steel Baskets: From Sheet to Precision Product

Stainless Steel Basket Manufacturing Workflow

-

1. Material Selection →

Premium 304/316L certified stainless steel sheet/wire, tested to ANSI/ISO standards for corrosion resistance & composition.

-

2. Sheet Cutting/Blanking →

Select laser or plasma cutting for dimensional accuracy.

-

3. Forming & Welding →

CNC bending for frames; high-precision TIG/MIG welding for mesh integration. Conforms to AWS D1.6.

-

4. Surface Treatment →

Electropolishing or sandblasting for smooth, contamination-free surfaces (especially for stainless steel basket kitchen products).

-

5. Inspection →

Dimensional tests, weld strength, salt-spray corrosion tests (ISO 9227)

-

6. Packing & Delivery

Protective packing, batch traceability, shipment arrangement.

Technical Advantages & Parameter Analysis of Stainless Steel Basket

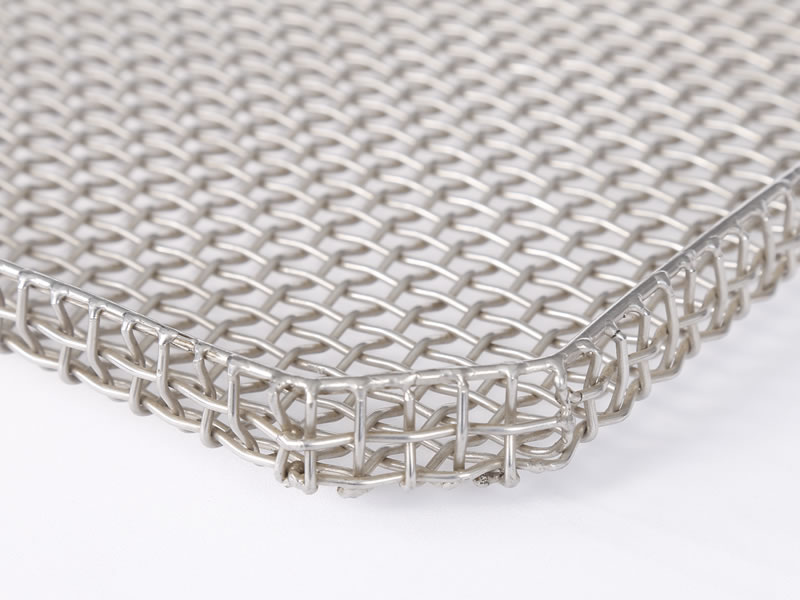

- Corrosion Resistance: With 18-20% chromium and 8-10.5% nickel (as in 304/316L), these baskets excel in harsh chemical, food processing, and high-humidity environments, preventing oxidation and rusting.

- Mechanical Strength: Yield strength ≥ 215MPa (304) allows stainless steel basket tray products to safely carry concentrated loads up to 50kg without permanent deformation (Tested: ASTM E8/E8M).

- Thermal Stability: End-use at temperatures up to 700°C for sintering, sterilization, or baking with minimal warpage.

- Hygienic & Food-Safe: Compliance with FDA CFR 21, and absence of micro crevices due to electropolished finish minimizes bacterial build-up – vital for kitchen baskets.

- Longevity: Lifecycle cost advantage—average service life exceeds 10-15 years, outperforming plastic/aluminum/iron baskets.

- Sustainability: 100% recyclable; meets circular economy standards in food, pharmaceutical, and water treatment industries.

Technical Indicator Comparison: Stainless Steel vs. Other Basket Materials

*Data represent averages from ASTM/BIS test reports, 2023.

Lifespan Distribution (Stainless Steel Basket)

*Empirical data compiled from user surveys and ISO 9227 salt spray tests.

Stainless Steel Basket Versatility: Application Scenarios, Customization & OEM Solutions

Key Application Scenarios

- Petrochemical process filter baskets

- Water & wastewater treatment (coarse/debris filtering, aeration trays)

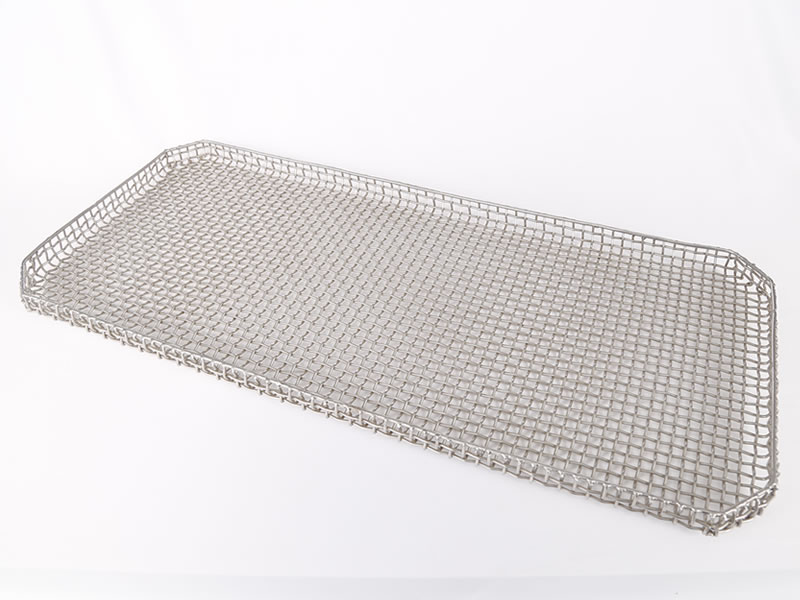

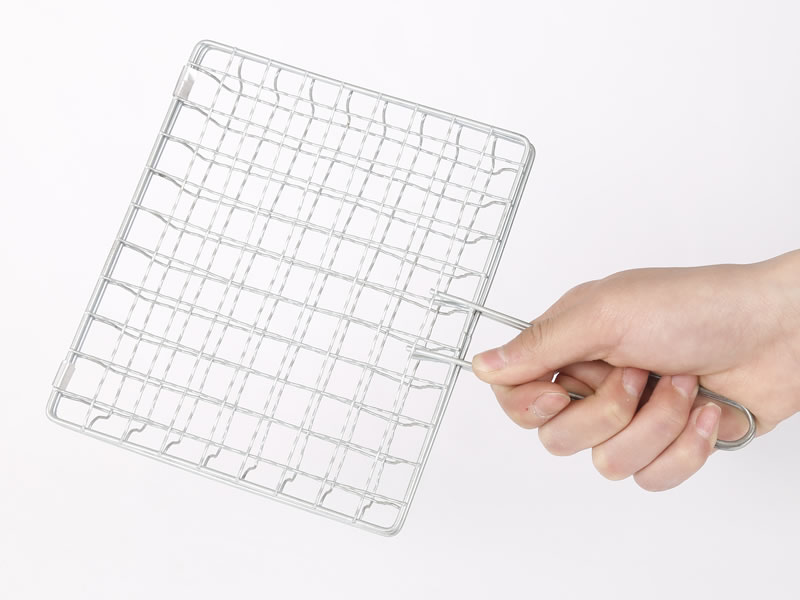

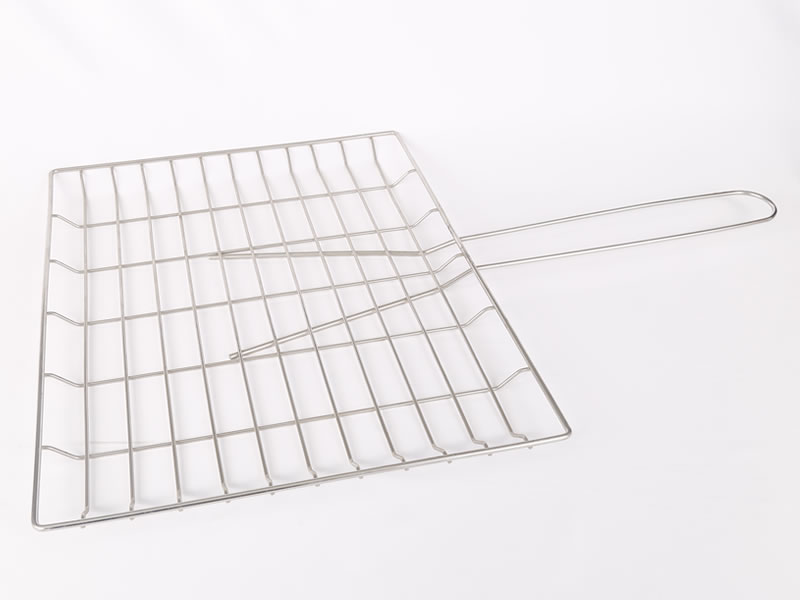

- Commercial kitchen: storage, draining, and steaming

- Baking and food preparation baskets

- Laboratory sample handling trays

- Steam sterilization racks (sterilizer basket)

- Parts cleaning baskets (auto/aviation industry)

- Pharmaceutical and hospital equipment

- Electronic component washing baskets

- Metalworking: annealing and sintering baskets

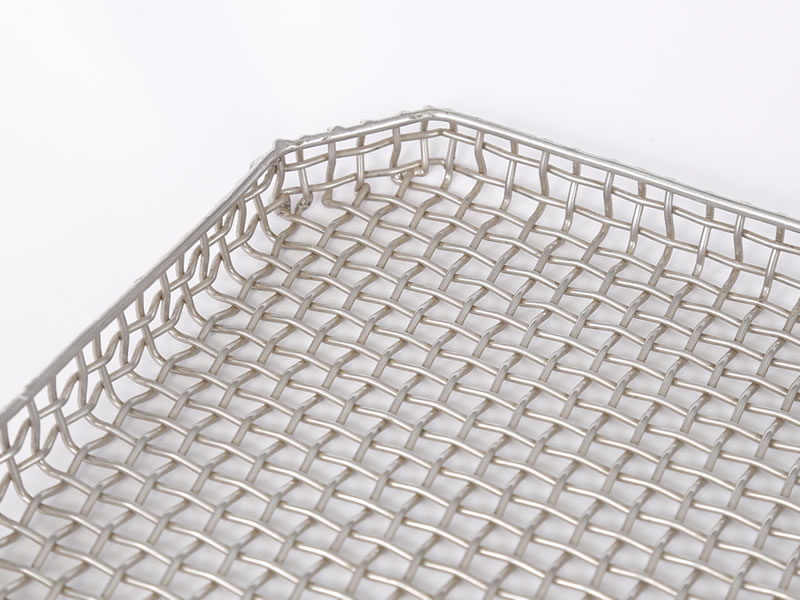

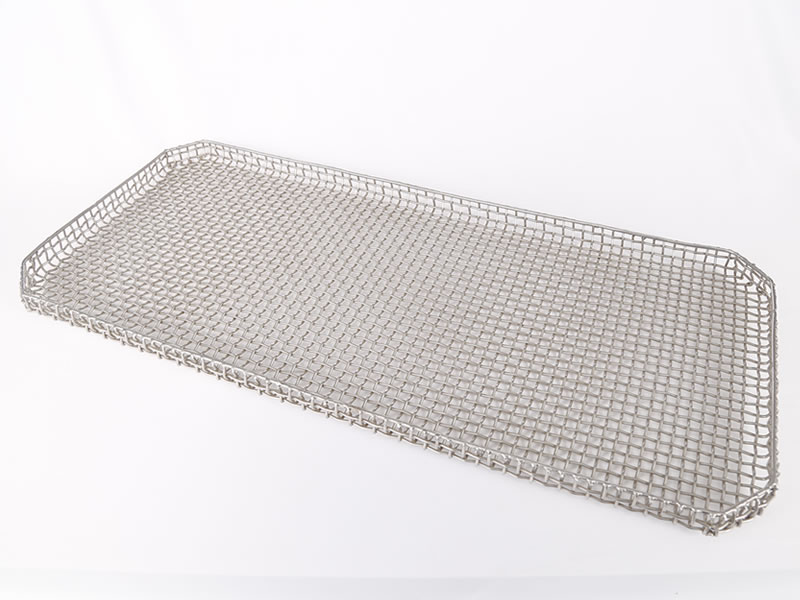

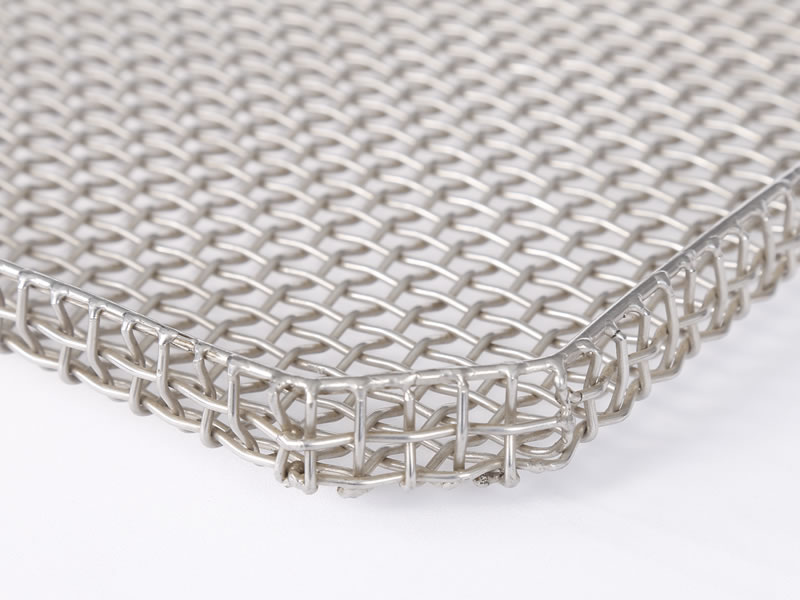

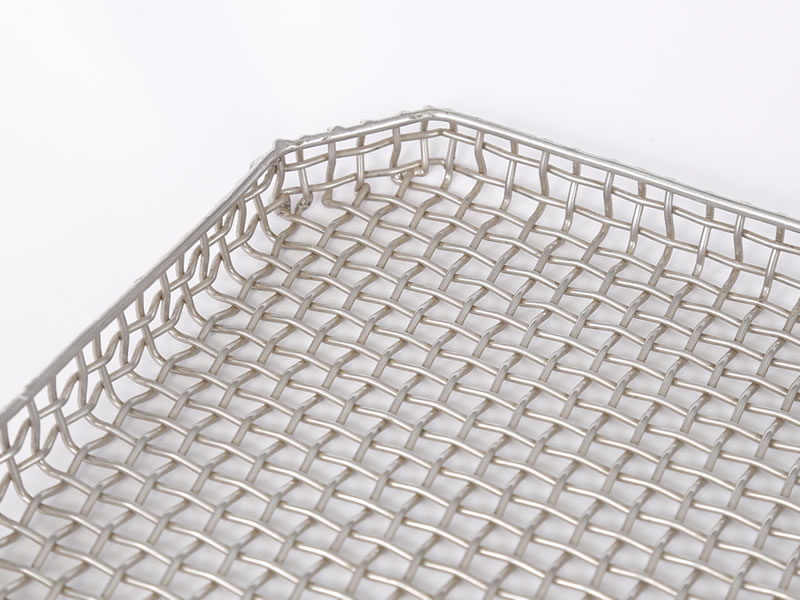

Customization Case Study: OEM Stainless Steel Basket for Filtration & Storage

- Client: Leading European automotive OEM

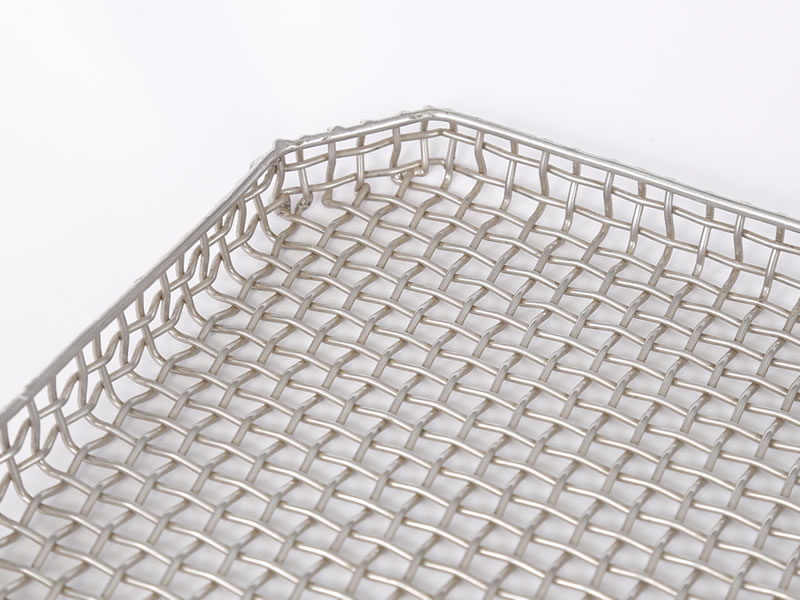

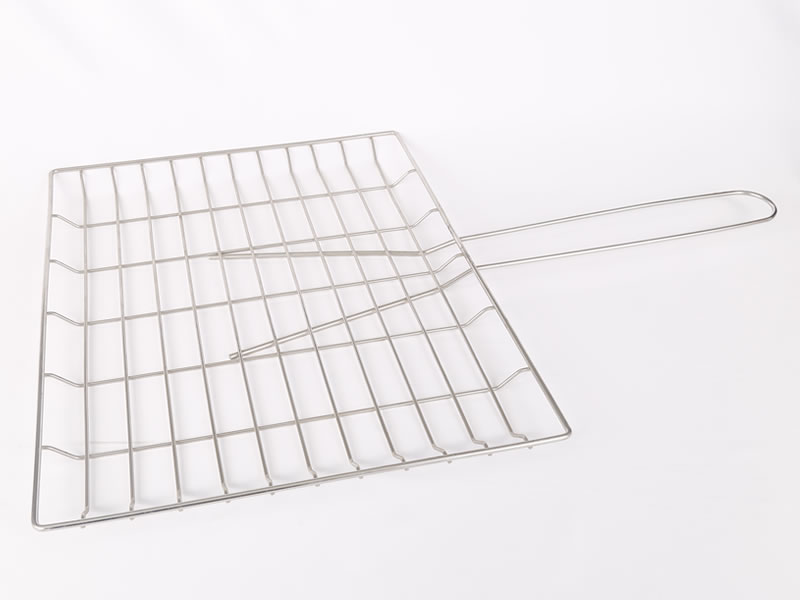

- Requirements: Acid-proof, 316L, mesh basket for parts washing; 600×400×125mm, with handles & stacking lips

- Design: Custom mesh size 1.5mm, load capacity 35kg, laser-etched batch trace code

- Result: 2400 pieces, passed ISO 9227 (salt spray) 720h - No corrosion; 4.8% unit cost reduction over previous supplier, service life stretched by 35%

Factory Comparison: Material, Process & Certification

Service & Support Capabilities

- Customization: Free CAD/3D drawing/engineering support, batch laser etching, nonstandard shapes

- Delivery: For standard stainless steel basket types, 3-7 days; for customized: 15-25 days depending on complexity and volume

- Quality Assurance: 2–5 years warranty; 100% product traceability; global after-sales support

- Certifications: ISO 9001, ISO 13485, FDA, SGS, other locally recognized quality marks on request

- References: Over 3,000 enterprise customers worldwide (OEM & ODM), including Fortune 500 factories

Frequently Asked Questions (FAQ): Stainless Steel Basket

Q1: What are the principal grades used for stainless steel basket manufacturing?

A: The most common grades are 304 (great overall performance & cost), and 316/316L (enhanced corrosion resistance using molybdenum, ideal for marine/chemical use). For food or kitchen, 304 is standard due to its non-toxicity.

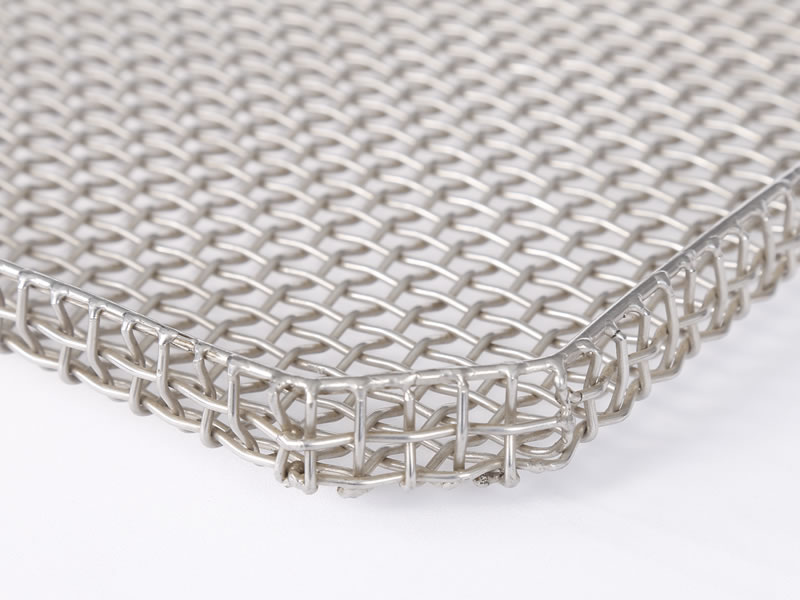

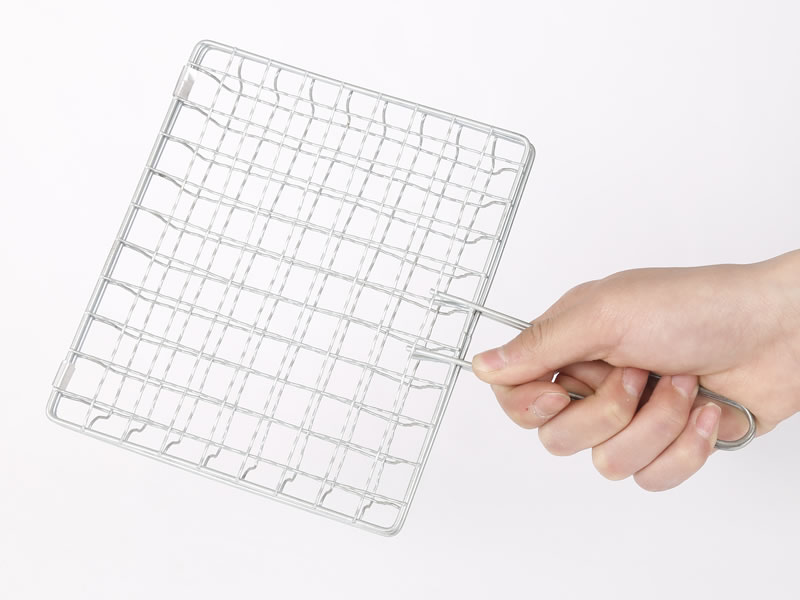

Q2: How to select the optimum mesh size and wire thickness?

A: This depends on application—fine filtration prefers 0.5-1mm mesh; general storage or kitchen use: 2–12mm mesh, wire thickness typically 1.5–4mm for robust stability.

Q3: What international standards do stainless steel baskets adhere to?

A: ISO 9001 (quality system), ASTM A240 (material), AWS D1.6 (welding), ISO 9227 (corrosion resistance), FDA CFR 21 (food contact), and occasionally EN 13485 (medical devices).

Q4: Can I get baskets with special surface finishes?

A: Yes, electropolishing (smoother, finer, best for pharma/food—Ra < 0.6 μm), pickling (standard), and powder coating (for color) are all supported. Electropolished baskets are notably easier to sterilize.

Q5: What installation and handling guidelines are recommended?

A: For industrial trays or baskets: align supports evenly, avoid overloading, regularly inspect welds for fatigue cracks, and follow local ISO/ANSI mounting standards where applicable.

Q6: Are stainless steel baskets compatible with aggressive chemicals?

A: 316L baskets withstand strong acids (up to 20% H2SO4, 10% HCl) at room temperature with minimal pitting; verify chemical compatibility charts for specifics.

Q7: What is the typical warranty and after-sales protocol?

A: Standard warranty: 24–60 months depending on type; 48-hour response window for claims, free spare parts for verified quality issues, and international on-site inspection arrangement on demand.

Customer Feedback & Real-World Application Cases

Case: Wastewater Treatment Plant (Europe)

- Application: Intake debris filtration in a municipal plant

- Basket: 10mm mesh, 316L, 900×600×250mm, electropolished

- Performance: 97% particle retention, 41% longer replacement interval vs. prior mild steel units

- Customer Quote: "After eight years, no noticeable corrosion or deformation, even in saline conditions."

Case: Commercial Kitchen Chain (USA)

- Application: Customized stainless steel basket kitchen for vegetable washing & draining

- Specification: 304 SS, 1.8mm wire, 8mm grid, stackable, mirror electropolished

- Result: Saved 32% cleaning time, eliminated prior plastic basket replacement costs

- Staff Feedback: "Easy to sterilize, space-efficient, looks premium on the prep line."

Data-Driven Selection: Why Choose Our Stainless Steel Basket?

- Proven Durability: Avg. replacement cycle: 13.7 years (user audit, 2022)

- Superior Cleanliness: Microbe test (ISO 22196): 50x fewer bacteria colonies compared to plastic trays after 12 hours’ use

- Traceable Quality: Each basket batch engraved for full traceability; test reports available

- International Compatibility: Products exported to 30+ countries; serviced by local partners

- Quality References: Used by Siemens, Nestlé, Mayr-Melnhof, and over 500 global manufacturers

Contact & Quote

For technical questions, engineering support, or custom order requests, visit our Stainless Steel Basket page or contact our certified engineers (English, German, Spanish, Chinese supported).

References & Further Reading:

[1] Grand View Research: Stainless Steel Market Analysis

[2] ResearchGate: Corrosion Resistance of Stainless Steel in Industry

[3] Metalworking Forums: Manufacturing Stainless Steel Wire Baskets Discussion