Stainless steel welded mesh plays a critical role across various industries, from construction and agriculture to security and filtration. This video offers an inside look at the complete production process of stainless steel welded mesh—highlighting the precision, innovation, and craftsmanship behind each sheet.

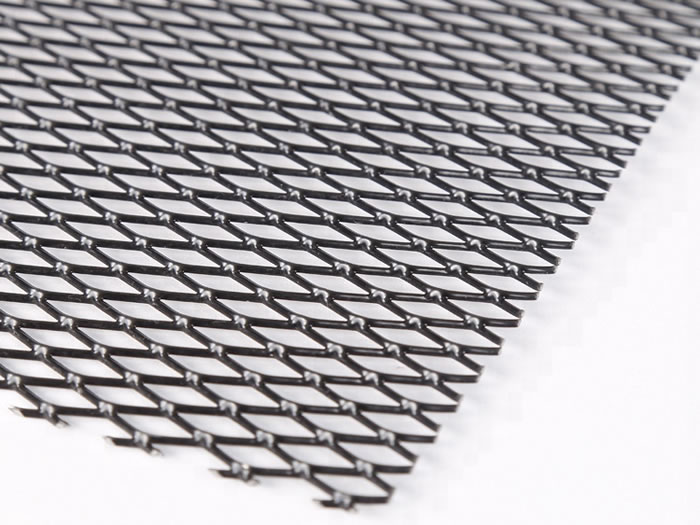

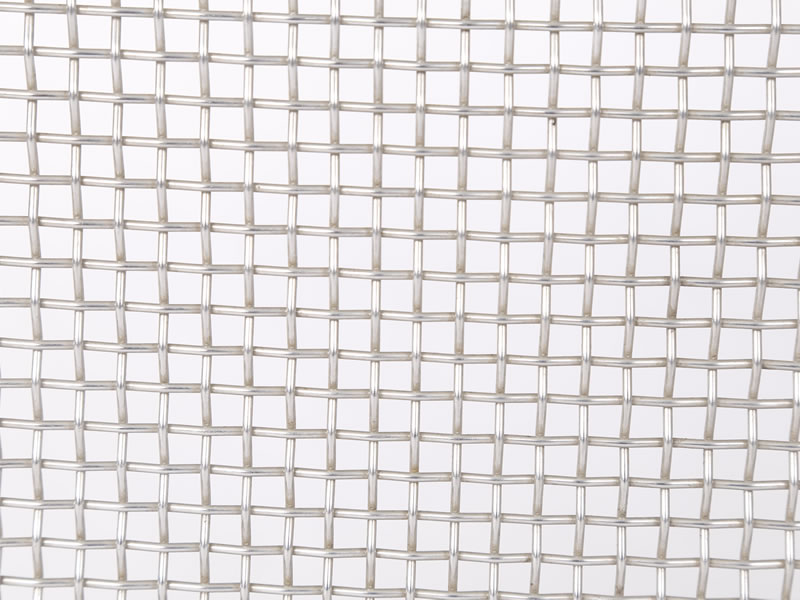

We begin with raw material selection, using premium-grade stainless steel wire—commonly 304 or 316—to ensure superior corrosion resistance, tensile strength, and durability. The video then transitions to the welding process, where automated resistance welding machines accurately join vertical and horizontal wires. These high-performance machines ensure each intersection is securely fused, resulting in a mesh with strong, uniform weld points and a consistent grid layout.

Next, the focus shifts to sizing and straightening. Once the mesh is welded, it is cut into specific dimensions according to customer requirements. Straightening machines then flatten and align the mesh panels to achieve an even surface, ensuring they meet strict quality standards for both aesthetics and function.

Surface treatment is a crucial step that enhances the mesh’s resistance to harsh environments. Processes such as pickling, passivation, or electro-polishing are applied to clean the surface, remove welding residues, and provide a smooth, bright finish.

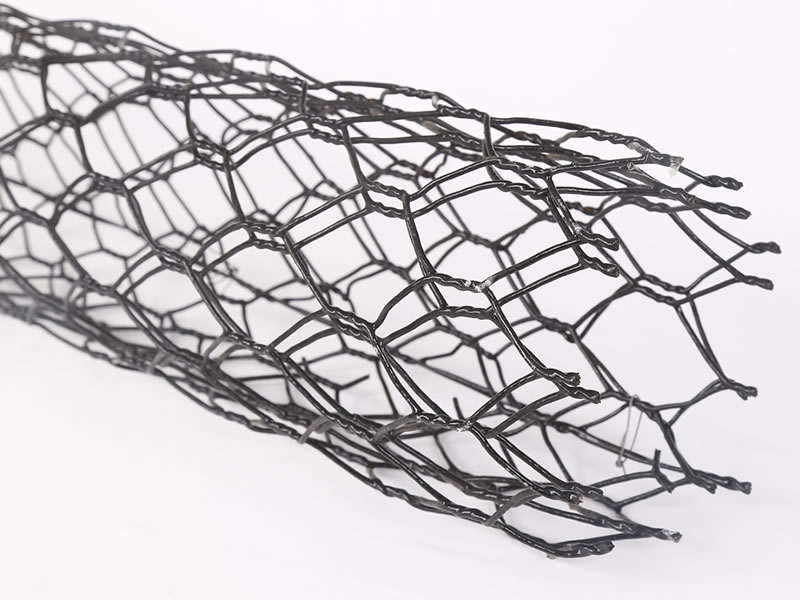

The video also highlights the wide range of applications for stainless steel welded mesh. In construction, it reinforces concrete and serves as protective fencing. In agriculture, it’s used for animal enclosures and crop support. In industrial settings, it forms part of machinery guards, ventilation panels, and filtration systems. Wherever strength, stability, and corrosion resistance are needed, stainless steel welded mesh proves its value.

Our manufacturing process combines advanced technology with strict quality control to deliver reliable mesh products for global markets.