Stainless steel wire is a foundational material in countless industries—serving roles in construction, automotive, electronics, medical devices, and more. This video takes you inside the production and properties of stainless steel wire, highlighting the technology, precision, and performance that define every spool.

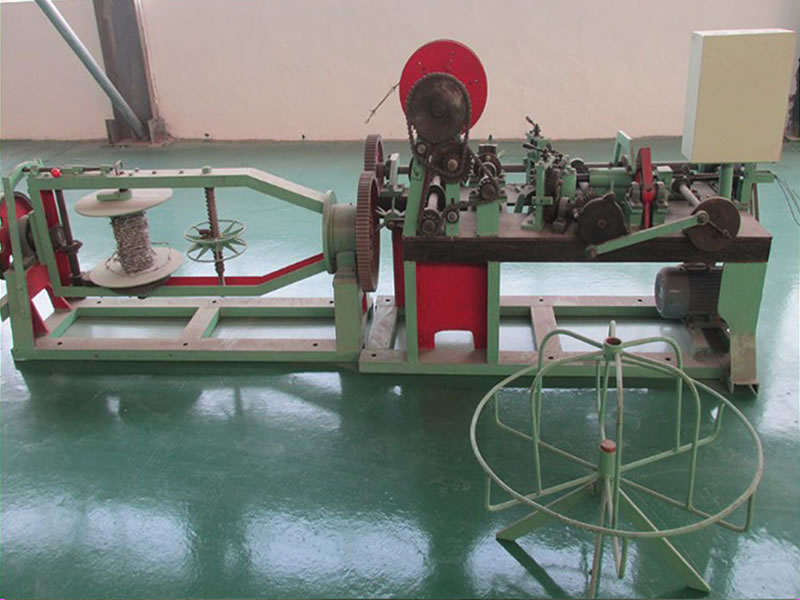

The journey starts with the selection of high-quality stainless steel billets, often from grades such as 304, 316, 302, or 430, depending on the required mechanical strength, corrosion resistance, and application. These billets are hot-rolled into rods, which are then drawn through a series of dies in a process known as wire drawing. This reduces the wire diameter while increasing tensile strength and achieving the desired thickness.

Throughout this stage, lubrication and cooling systems play a crucial role in maintaining surface integrity and reducing friction. The wire is drawn to various gauges, from ultra-fine diameters for medical or electronic use to thicker gauges for structural and industrial purposes.

After drawing, the wire undergoes heat treatment—typically annealing—to relieve internal stresses and restore ductility. This process is essential for ensuring the wire can be further processed or formed without cracking. The wire is then cleaned, either through acid pickling or electro-cleaning, to remove any oxide scales and surface impurities.

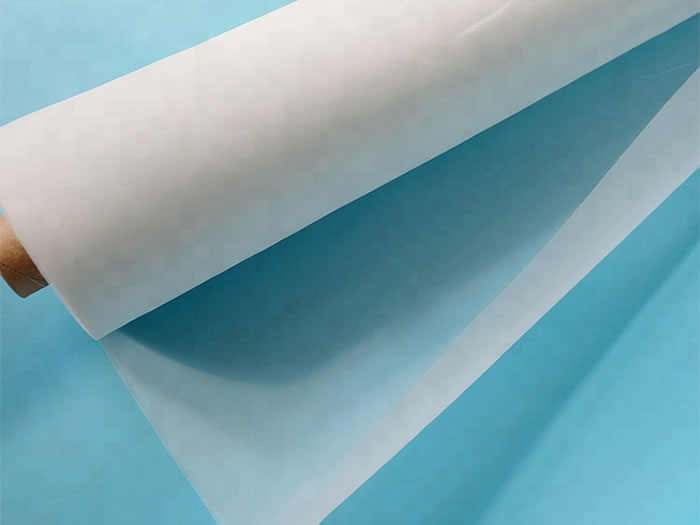

Surface finishes vary based on end use. For example, bright finish wire is used in springs or decorative products, while matte or coated surfaces may suit industrial needs. Precision winding onto spools, coils, or reels ensures easy handling and transport while protecting the wire’s surface.

The video also highlights extensive quality control measures, including diameter testing, tensile strength analysis, elongation checks, and surface inspections. Each batch is manufactured to meet global standards, including ASTM, DIN, or ISO, depending on the target market.

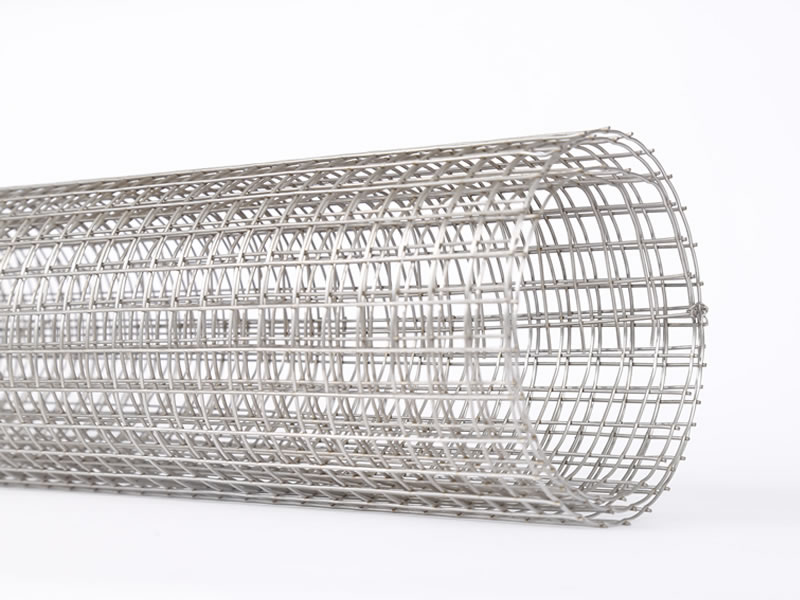

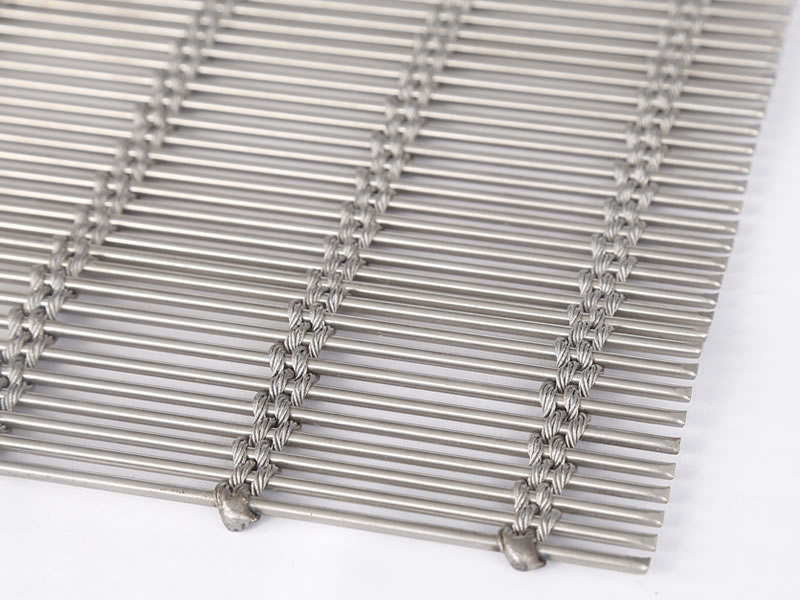

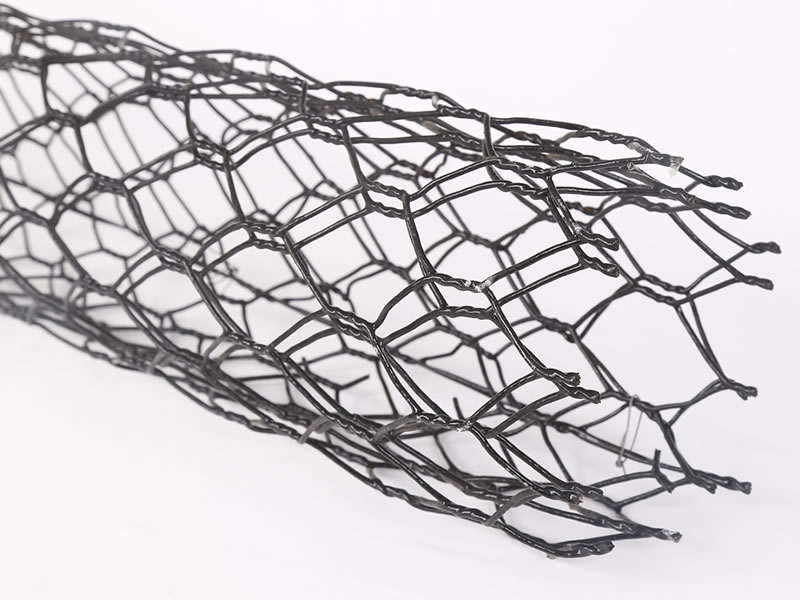

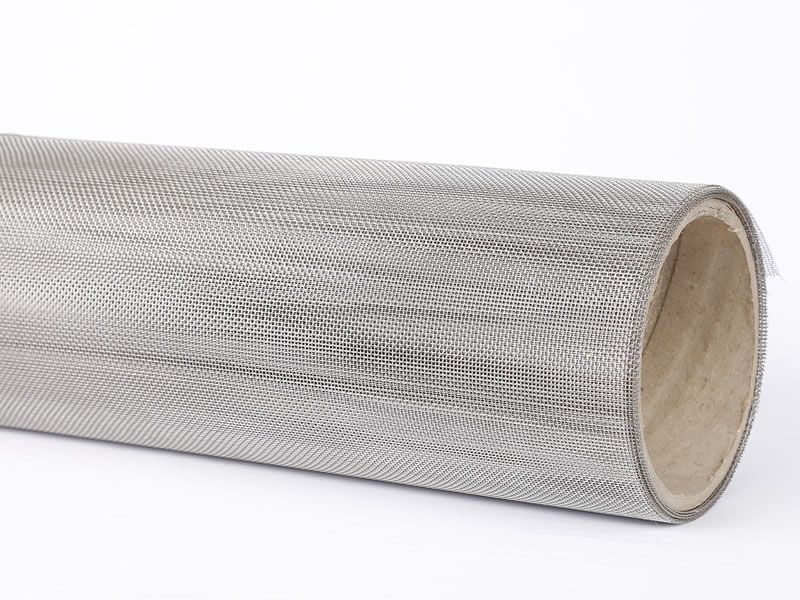

Finally, the video showcases the incredible versatility of stainless steel wire. It’s used in mesh production, springs, wire ropes, surgical instruments, welding electrodes, fasteners, and more. The combination of corrosion resistance, strength, and formability makes stainless steel wire a critical material for demanding environments.