This video provides a comprehensive overview of the stainless steel mesh preparation process—an essential foundation for high-quality performance in industrial, architectural, and commercial applications. From selecting raw materials to precise processing techniques, every step ensures the durability, precision, and versatility of the final mesh product.

The journey begins with the careful selection of stainless steel wire. Typically made from grades such as 304, 316, or 316L, these wires are chosen for their corrosion resistance, strength, and suitability for various environmental conditions. The wire is then cleaned and straightened to remove any surface contaminants and ensure uniform tension, which is vital for accurate mesh construction.

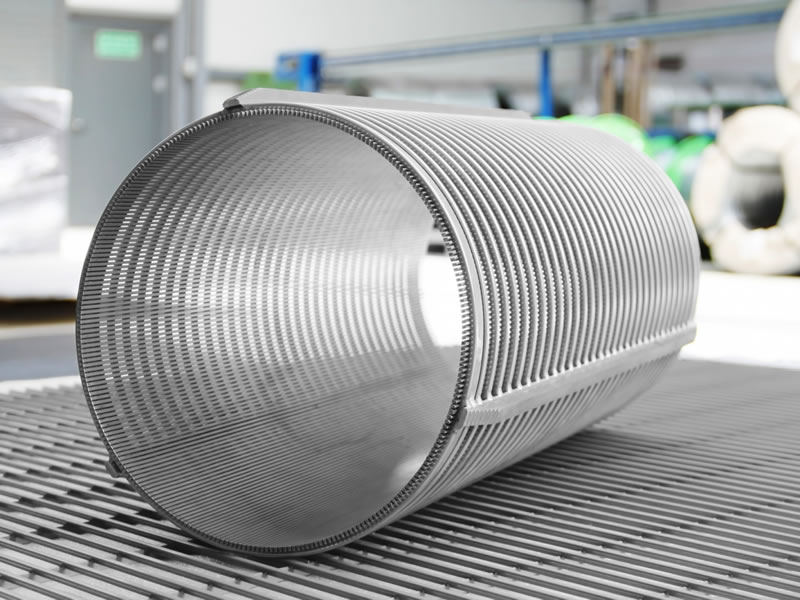

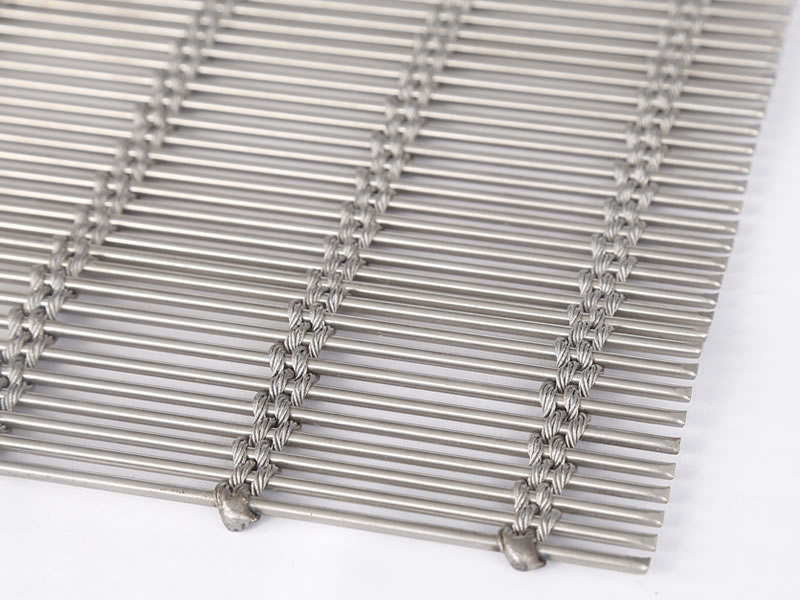

The next stage features the core preparation process: weaving or welding. In woven mesh preparation, precision looms interlace wires into specific patterns such as plain weave or twill weave, creating consistent mesh openings. For welded mesh, resistance welding fuses intersecting wires at fixed intervals, creating rigid, flat panels with uniform spacing.

Once the mesh structure is formed, it moves to the finishing stage. Surface treatments such as pickling, passivation, or electro-polishing are applied to remove scale, oxidation, and impurities from the mesh surface. This not only enhances the material’s corrosion resistance but also improves its appearance, especially important in architectural or hygienic applications.

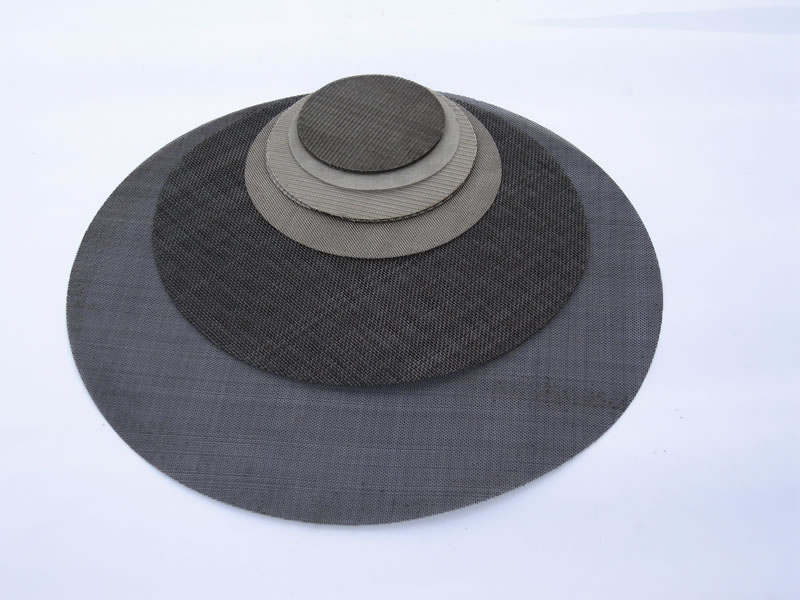

After surface finishing, the mesh is flattened and cut into specified dimensions. Automated equipment ensures accuracy and consistency, whether the mesh is destined for rolls, panels, or custom-fabricated components. Quality control is implemented throughout, including visual inspection, dimensional checks, and, in some cases, tensile strength testing to ensure each batch meets industry standards.

The video concludes by showcasing the wide range of uses for prepared stainless steel mesh—from filtration and ventilation to fencing, security enclosures, and reinforcement materials. With its strength, flexibility, and resistance to corrosion, stainless steel mesh is an indispensable material in modern industry.